A pet antistatic coil

An anti-static and coil technology, applied in the field of polymer films, can solve the problems of insufficient anti-static performance, discounted anti-static ability, large frictional static voltage value of polymers, etc., and achieve uniform and stable anti-static performance and service life. Long, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

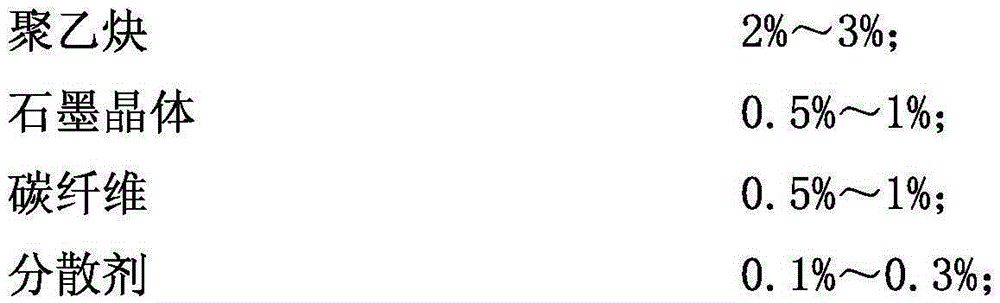

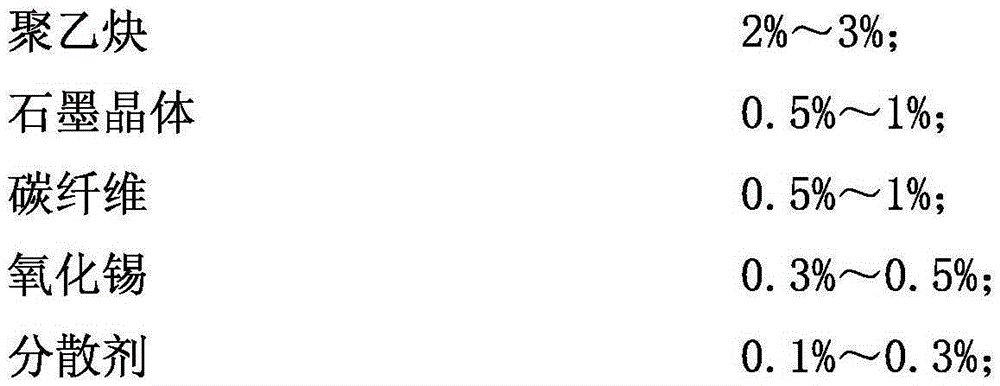

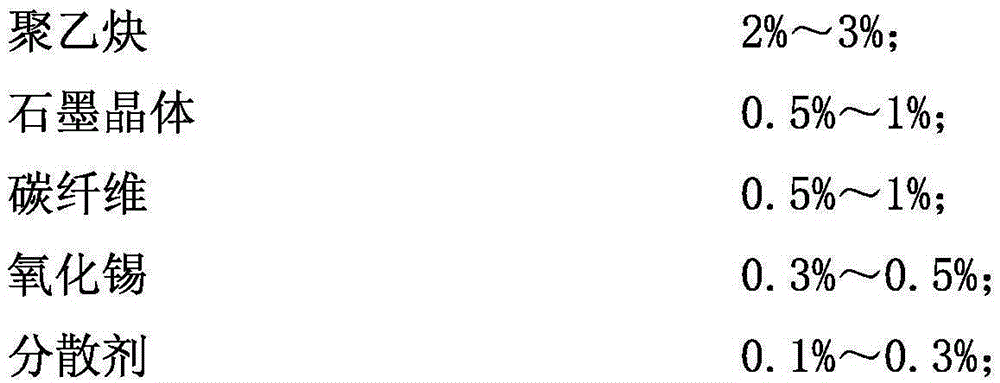

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0022] Antistatic agents can generally be divided into two types, external coating type and internal mixing type. External coating antistatic agent refers to a kind of antistatic agent used on the surface of polymer materials. It is generally formed by coating, spraying or dipping on the surface of polymer materials, and then dried at room temperature or hot air. Antistatic coating. Although this kind of external antistatic agent is suitable for many kinds of polymers, their effectiveness is only temporary, and it is easy to lose after contact with solvent or friction with other objects. In-mix antistatic agent refers to a type of antistatic agent added to the resin during the processing of the product. Usually the resin and a certain quality of antistatic agent are mechanically mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com