Aluminium alloy semi-solid preform body and preparation method thereof

A semi-solid, aluminum alloy technology, which is applied in the field of preparation of aluminum alloy semi-solid blanks, can solve the problems of low mechanical properties and poor corrosion resistance of semi-solid blanks, and achieve high tensile strength, good corrosion resistance, and technological conditions. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

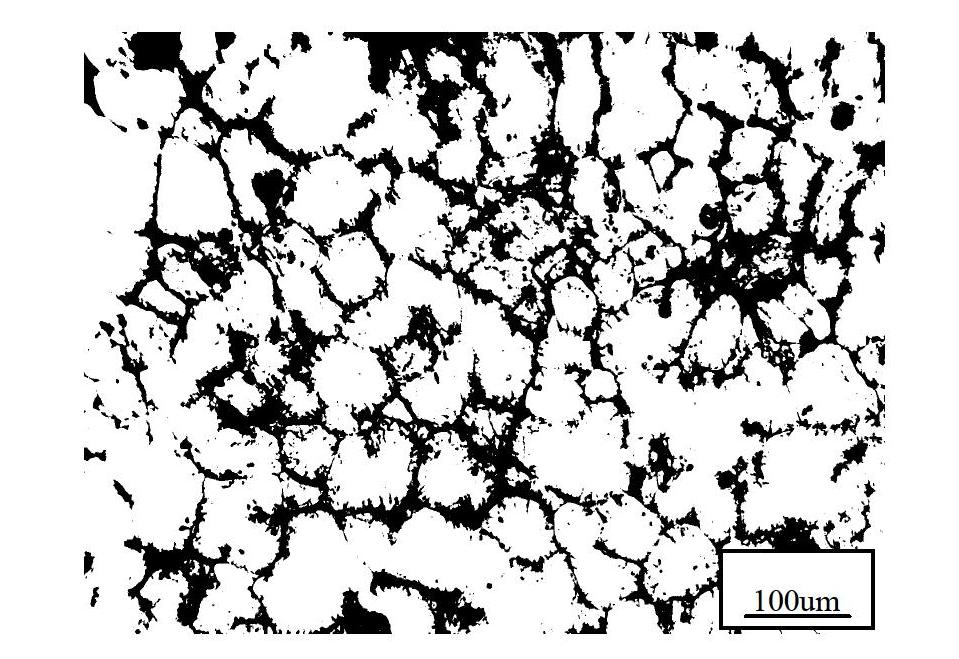

[0020] Example 1, an aluminum alloy semi-solid billet, which is LC4 deformed aluminum alloy, consists of the following components: Zn: 5.58wt%, Mg: 2.40wt%, Cu: 1.58wt%, Cr0.21wt%, Si: 0.3wt% %, Fe: 0.35wt%, Mn: 0.2wt%, and the balance is Al. The liquidus temperature of the alloy is 620°C. After melting the alloy in an intermediate frequency induction furnace, the temperature of the alloy melt is 690-710°C. The melt is transferred to a standing furnace for refining and slag removal. After refining, it is melted The body temperature is 680-690°C, and then the molten metal is transferred into the tundish for ultrasonic vibration semi-continuous casting. The tundish temperature is controlled at 690-700°C, the ultrasonic vibration frequency is 30000HZ, the metal mold preheating temperature is controlled at 395-405°C (ultrasonic treatment time is 12s), the ultrasonic power is 300W, and the ultrasonic wave is introduced for stirring to obtain a semi-solid Blank, its metallographic ...

Embodiment 2

[0021] Example 2, an aluminum alloy semi-solid billet, which is LC9 deformed aluminum alloy, consists of the following components, Zn: 5.64wt%, Mg: 2.57wt%, Cu: 1.63wt%, Cr0.16wt%, Si: 0.2wt% %, Fe: 0.25wt%, Al balance. First melt the alloy in a resistance furnace, refine it at 690°C and let it stand for 10 minutes to remove slag, then put it into an ultrasonic vibration head for vibration, the ultrasonic vibration frequency is 20000HZ, the ultrasonic power is 200W, and the vibration temperature of the aluminum liquid is controlled at 675 -685°C, mold preheating temperature is 195-205°C. The tensile properties of the thus obtained semi-solid material are as follows: Rm=310MPa, Rs=220MPa, A=2%.

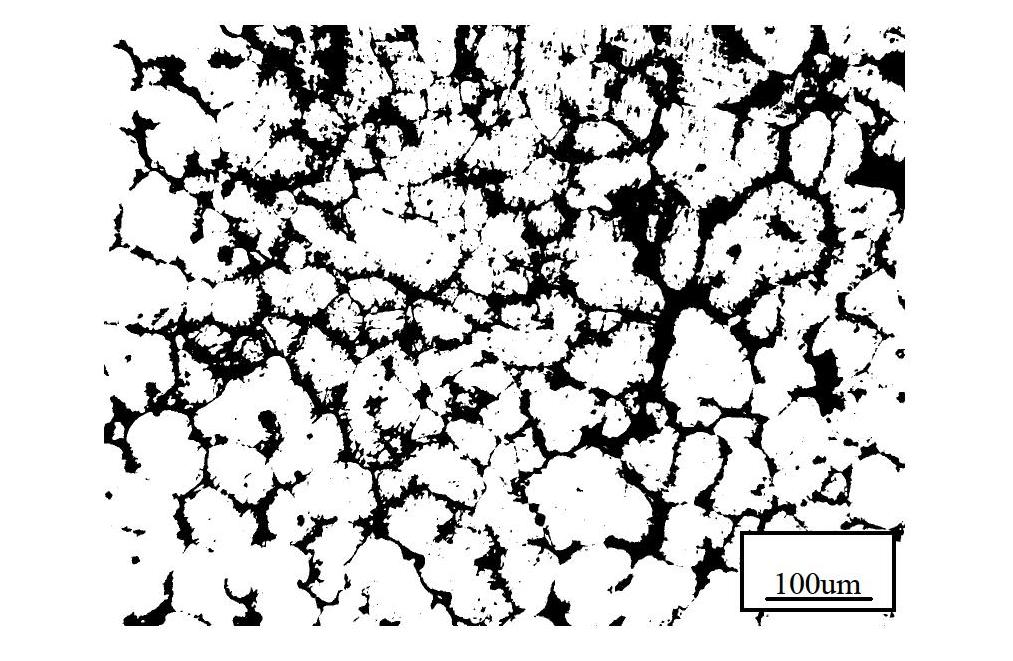

[0022] The semi-solid material is heat treated. The heat treatment process is 480°C×4h solid solution, 175°C×5h aging. After heat treatment, dissection, rough grinding, fine grinding and polishing, the metallographic sample was prepared and etched with 0.5% HF aqueous solution. The ...

Embodiment 3-23

[0023] Example 3-23, an aluminum alloy semi-solid billet, is LC9 deformed aluminum alloy, see Table 1 for composition, see Table 2 for process conditions, and the rest are the same as Example 1.

[0024] The composition of table 1 embodiment 3-23

[0025]

[0026] The process condition of table 2 embodiment 3-23

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com