Method for achieving TWIP steel superplasticity based on deformation twin degradation

A technology of deformation twinning and superplasticity, which is applied in the field of metal material forming and superplastic deformation, can solve the problems of large deformation of TWIP steel, low difficulty in processing and production, and high deformation resistance, so as to reduce the requirements for control accuracy and reduce energy consumption. Cost-effective, fast forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

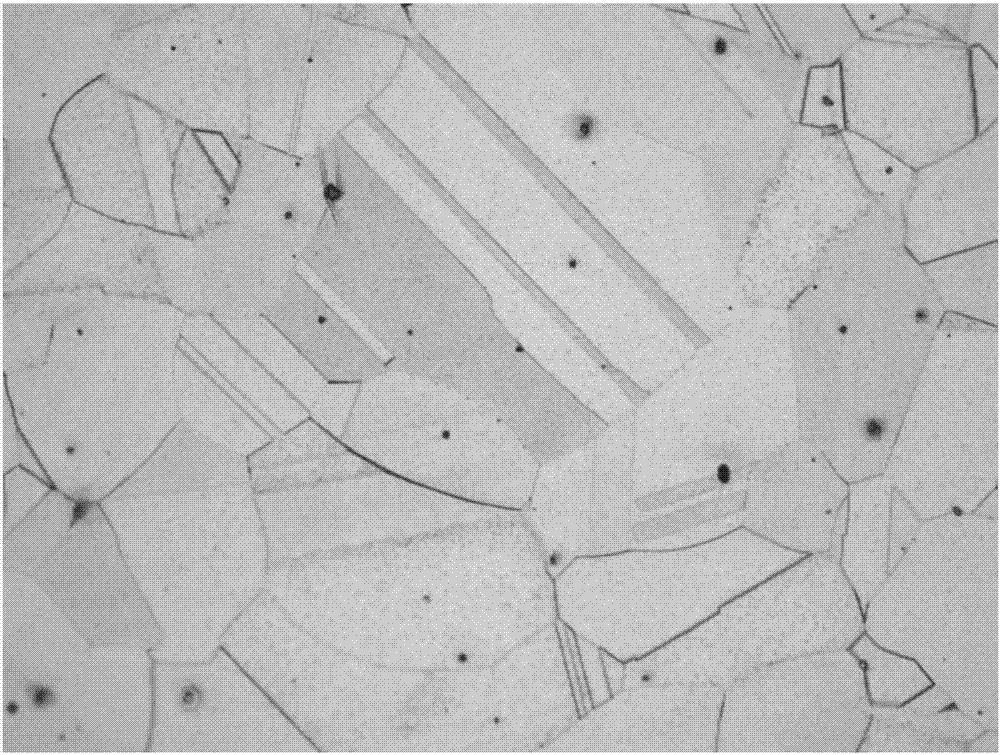

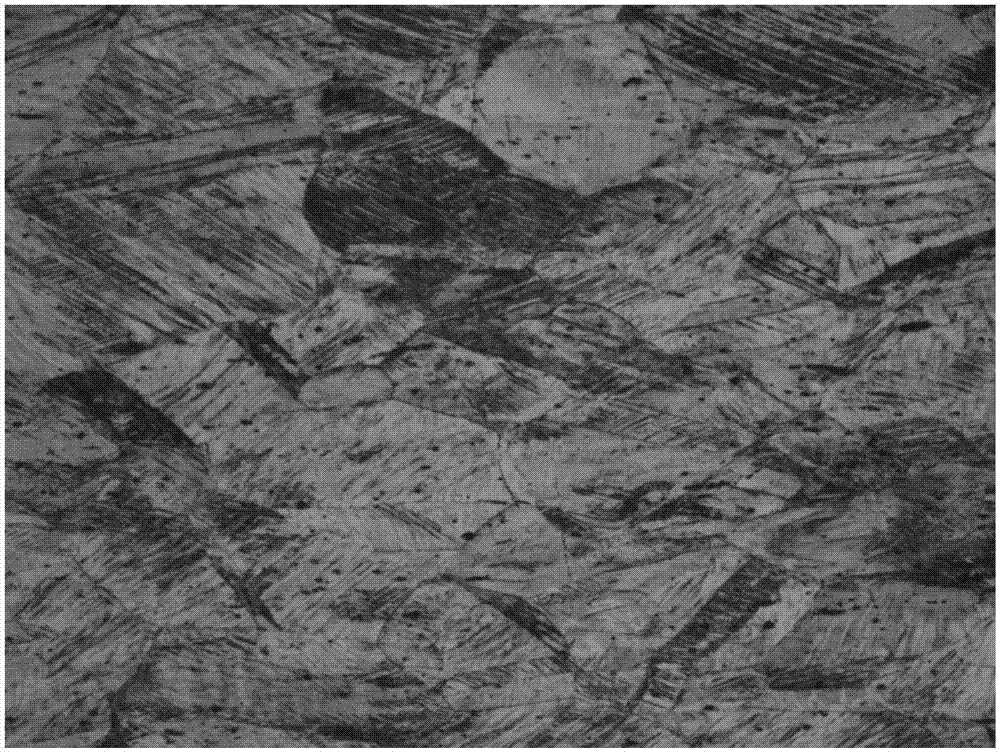

[0035] 1) TWIP steel bar is used, and its microstructure is shown in figure 1 , stretch it at room temperature, the tensile deformation rate is 1mm / s, the deformation amount is 40%, the microstructure after stretching can be seen figure 2 ;

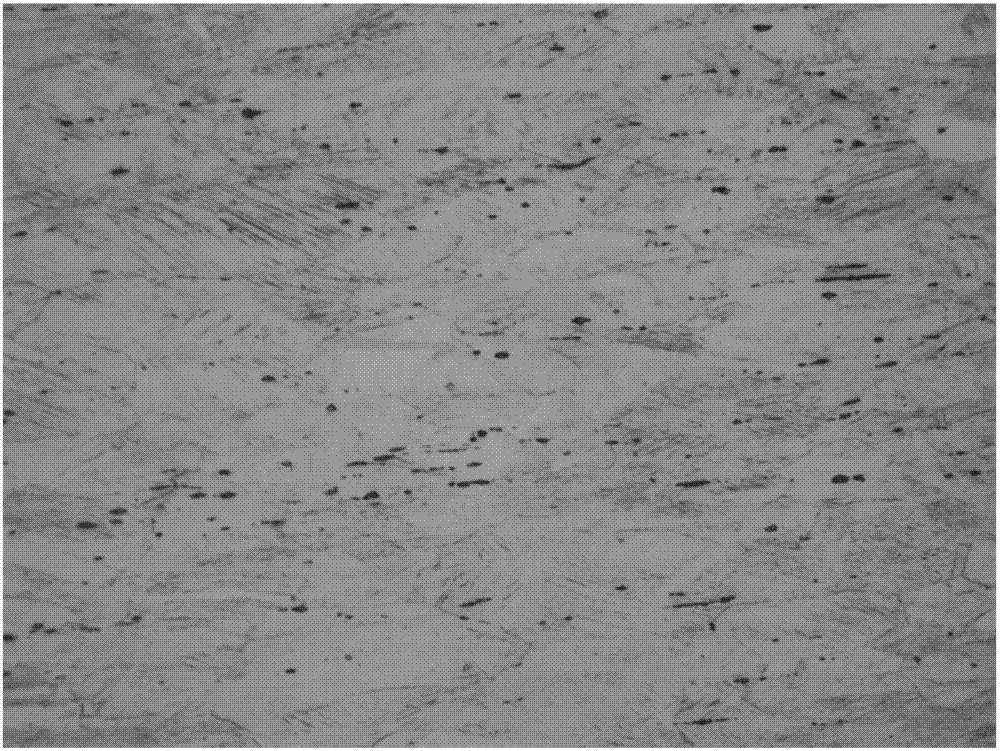

[0036] 2) Deformation twin degeneration treatment, holding temperature: 650°C, holding time 60min, quenching after heat treatment, the microstructure after quenching can be seen image 3 ;

[0037] 3) Stretch the TWIP steel bar at room temperature, the tensile deformation rate is 1mm / s, and the deformation amount is 30%;

[0038] 4) Deformation twin degeneration treatment, the holding temperature is 650°C, the holding time is 60min, and quenching is carried out after heat treatment;

[0039] 5) Stretch the TWIP steel bar at room temperature, and the tensile deformation rate is 10 -1 mm / s, deformation is 30%;

[0040] 6) Deformation twin degeneration treatment, the holding temperature is 650°C, the holding time is 60min, and quenchin...

Embodiment 2

[0043]1) Stretch the TWIP steel bar at room temperature, the tensile deformation rate is 5mm / s, and the deformation amount is 40%;

[0044] 2) Deformation twin degeneration treatment, the holding temperature is 850°C, the holding time is 30min, and quenching is carried out after heat treatment;

[0045] 3) Stretch the TWIP steel bar at room temperature, the tensile deformation rate is 1mm / s, and the deformation amount is 30%;

[0046] 4) Deformation twin degeneration treatment, the holding temperature is 850°C, the holding time is 30min, and quenching is carried out after heat treatment. After quenching, the microstructure can be seen Figure 4 ;

[0047] 5) Stretch the TWIP steel bar at room temperature, and the tensile deformation rate is 10 -1 mm / s, deformation is 30%;

[0048] 6) Deformation twin degeneration treatment, the holding temperature is 850°C, the holding time is 30min, and quenching is carried out after heat treatment;

[0049] After measurement, the total e...

Embodiment 3

[0051] 1) Stretch the TWIP steel bar at room temperature, the tensile deformation rate is 10mm / s, and the deformation amount is 40%;

[0052] 2) Deformation twin degeneration treatment, the holding temperature is 650°C, the holding time is 30min, and quenching is carried out after heat treatment;

[0053] 3) The TWIP steel bar is stretched at room temperature, and the tensile deformation rate is 10 -1 mm / s, deformation is 30%;

[0054] 4) Deformation twin degeneration treatment, the holding temperature is 650°C, the holding time is 30min, and quenching is carried out after heat treatment;

[0055] 5) Stretch the TWIP steel bar at room temperature, and the tensile deformation rate is 10 -1 mm / s, deformation is 30%;

[0056] 6) Deformation twin degeneration treatment, the holding temperature is 650°C, the holding time is 30min, and quenching is carried out after heat treatment. After quenching, the microstructure can be seen Figure 5 .

[0057] from Figure 5 It can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com