Preparation method for low-carbon production of refined corundum mullite high-temperature material

A technology for refining corundum and high-temperature materials is applied in the field of low-carbon production of refined corundum-mullite high-temperature materials. Guarantee the effect of molding performance and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

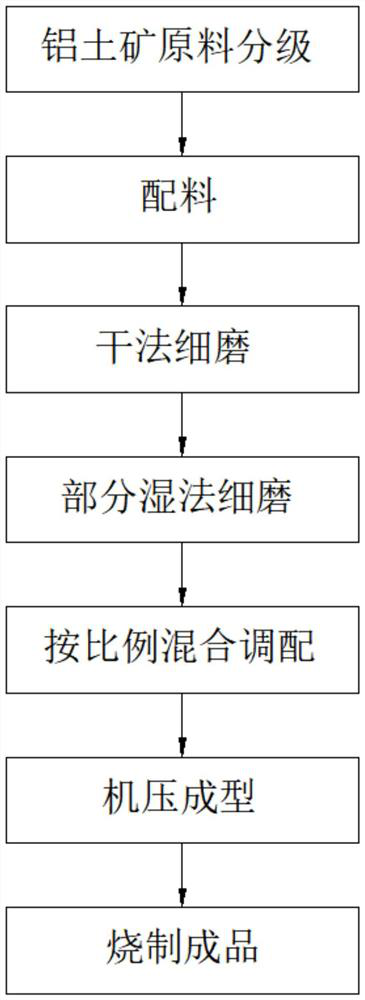

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] A low-carbon preparation method for producing refined corundum-mullite high-temperature materials, the method comprising the following steps:

[0025] Step 1: Classify the bauxite raw materials, group and adjust the bauxite raw materials according to their chemical components;

[0026] Step 2: batching, blending the graded bauxite raw material into a material with an aluminum content of 88.5% after firing;

[0027] Step 3: dry fine grinding, the bauxite raw material prepared by dry method is finely ground, and the D50 is 6 μm;

[0028] Step 4: partial wet fine grinding, wet fine grinding is carried out on some raw materials of the same batch to obtain fine grinding mud, and the D50 of the fine grinding mud is 2.8 μm;

[0029] Step 5: Mix and prepare according to the proportion, fully stir the above-mentioned dry fine grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com