Sealing structure for sealing multiple joints

A technology of sealing structure and joint surface, applied in the direction of engine sealing, mechanical equipment, engine components, etc., to achieve the effect of improving production efficiency, increasing costs, and optimizing sealing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

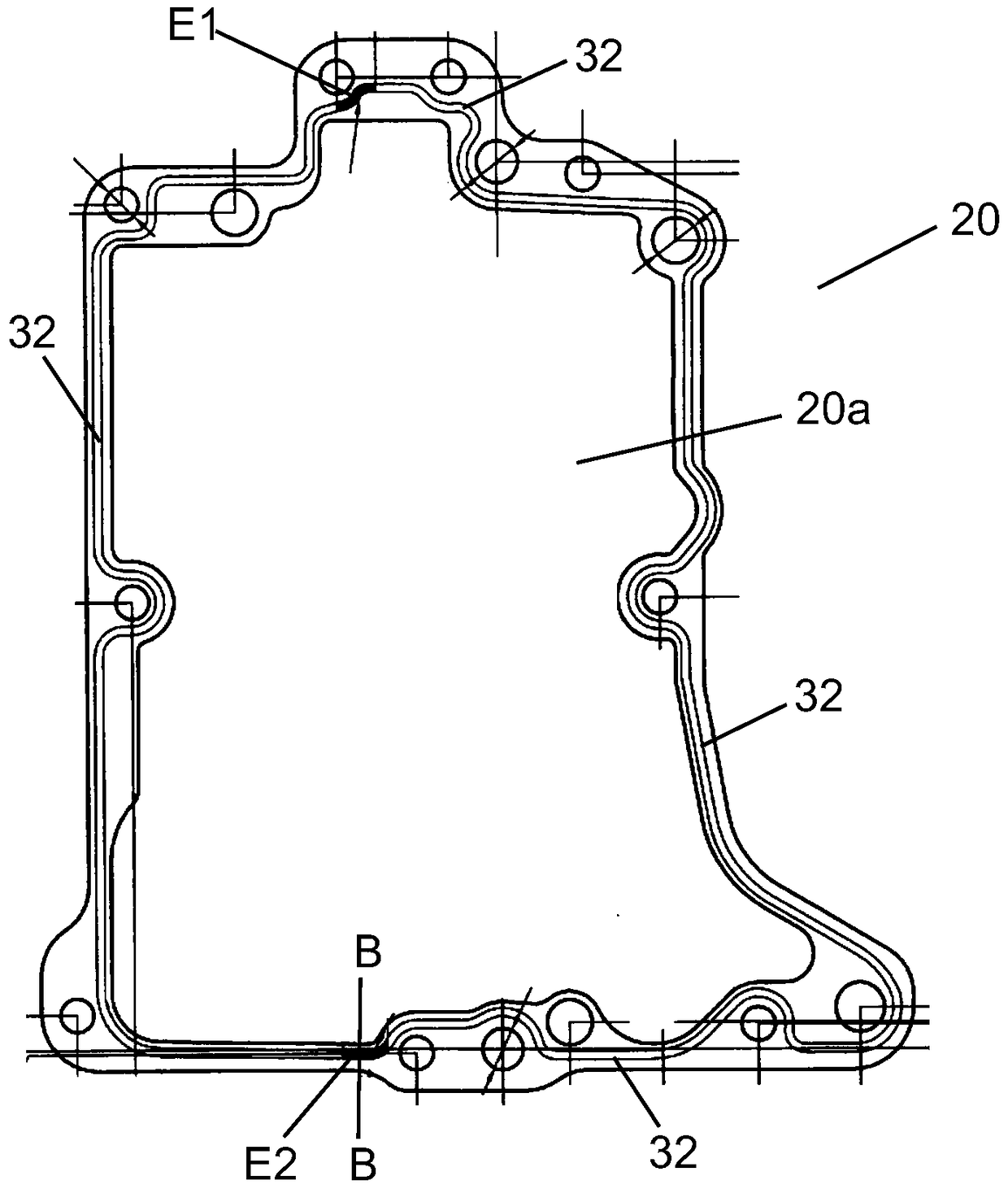

[0022] The sealing structure of the preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

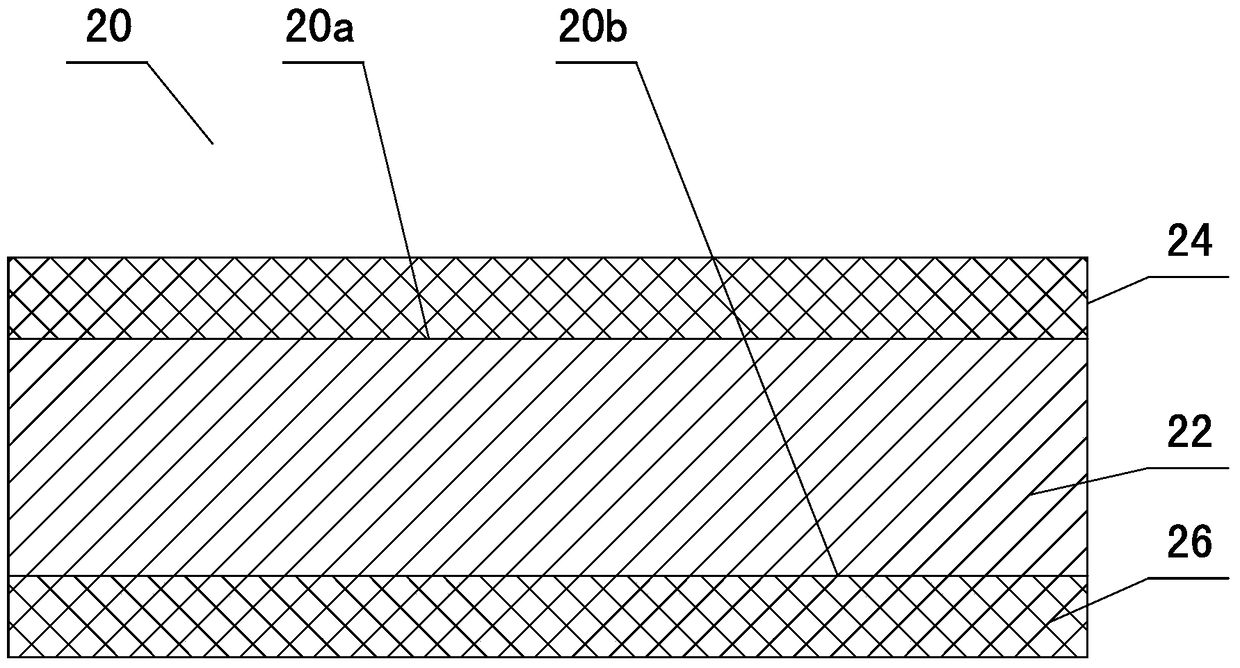

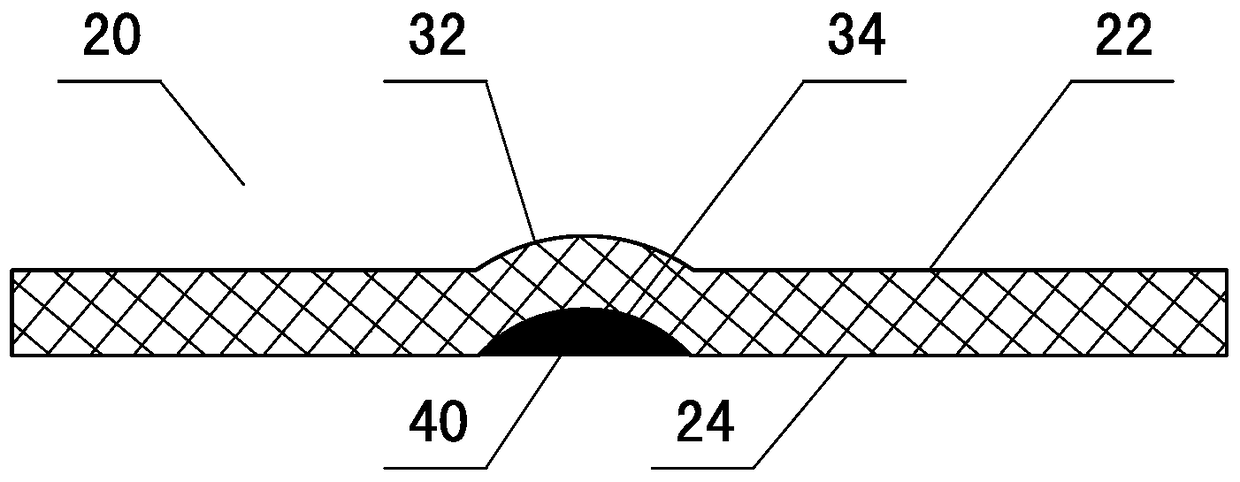

[0023] According to the present invention, the sealing structure for sealing multi-joint surfaces is mainly composed of a three-layer structure, the metal layer in the middle provides rigidity for the sealing structure, and the two-layer rubber composite material layer is assembled between the multi-joint surfaces when the force is applied. Microscopic unevenness of the joint surface can be filled. The sealing structure of the invention is especially suitable for the multi-joint surface sealing in the box body of the automobile power assembly. On the one hand, it can ensure the sealing effect, on the other hand, it will not adversely affect the cleanliness inside the powertrain.

[0024] figure 1 A cross-sectional view of a sealing structure according to a preferred embodiment of the present invention is shown. Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com