High-elongation high-strength hot-dip galvanized steel sheet and production method thereof

A technology of hot-dip galvanized steel and high elongation, which is applied in the field of iron and steel smelting to achieve the effects of improving stability, reducing costs, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

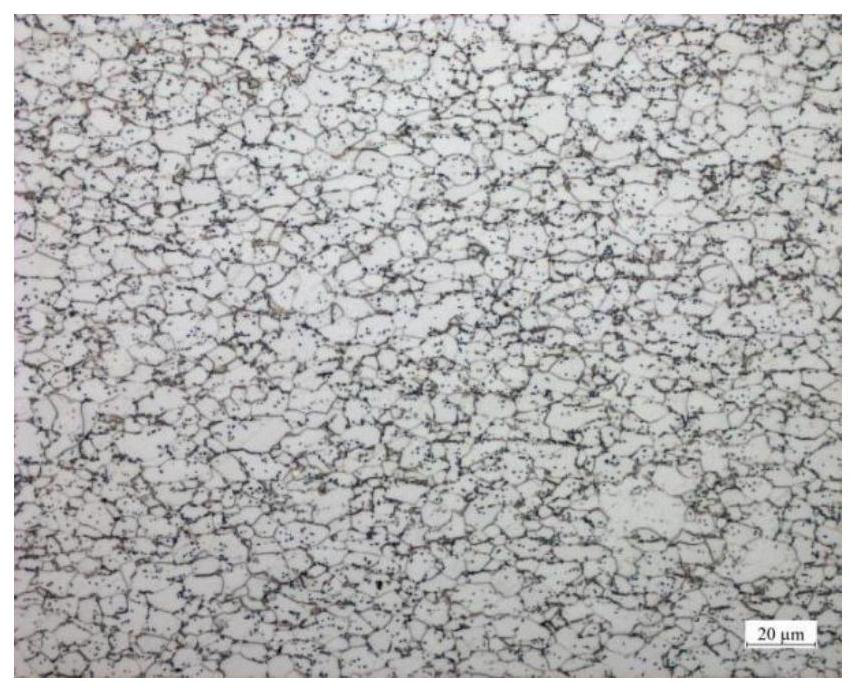

Image

Examples

Embodiment 1

[0039] (1) Smelting process: through the smelting process, prepare a hot-dip galvanized steel billet with chemical composition as shown in Table 1; billet thickness 230mm;

[0040] (2) Hot rolling process: heat the billet to 1233°C, and use 5 passes of rough rolling for 263 minutes in the furnace. After rough rolling, the thickness of the middle slab is 42 mm. The rolling temperature is 907°C, rolling is carried out, and then sparsely cooled, the cooling rates of the upper and lower surfaces are 50% and 75% respectively, and finally coiled at 607°C to obtain a hot-rolled sheet with a thickness of 3.0mm;

[0041] (3) Pickling process: After the hot-rolled coil is pickled, it is cold-rolled into thin strip steel, and the cold-rolling reduction rate is 62.5%;

[0042] (4) Annealing and hot-dip galvanizing process: the thin strip is heated to 300°C at a heating rate of 17°C / s, heated to 700°C at a heating rate of 10°C / s, and heated to 761°C at a heating rate of 4°C / s After holdin...

Embodiment 2

[0044] (1) Smelting process: through the smelting process, prepare the hot-dip galvanized steel billet of chemical composition as shown in Table 1;

[0045] (2) Hot rolling process: heat the billet to 1233°C, and use 5 times of rough rolling in the furnace for 263 minutes. After rough rolling, the thickness of the middle slab is 42mm. The rolling temperature is 893°C, and then sparsely cooled, the cooling rates of the upper and lower surfaces are 50% and 75% respectively, and finally coiled at 587°C to obtain a hot-rolled sheet with a thickness of 3.0mm;

[0046] (3) Pickling process: After pickling the hot-rolled coils, they are cold-rolled into thin strips; the cold-rolling reduction rate is 61.0%.

[0047] (4) Annealing and hot-dip galvanizing process: the thin strip steel is heated to 300°C at a heating rate of 18.5°C / s, heated to 700°C at a heating rate of 11°C / s, and heated to 768°C at a heating rate of 4.5°C / s And keep it at 768°C for 58s, then cool slowly at 1.3°C / s t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com