Forming method for achieving different-area performance stable transition of high-strength steel hot-forming part

A technology of hot forming and high-strength steel, which is applied in the field of hot stamping forming, can solve the problems such as the reduction of formability, achieve the effects of ensuring formability, reducing production costs, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

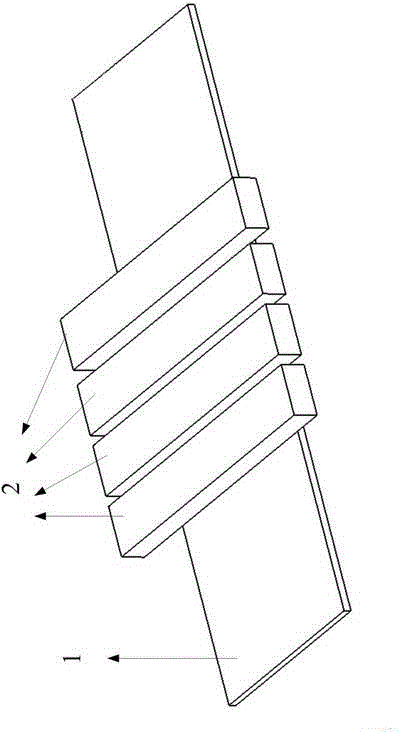

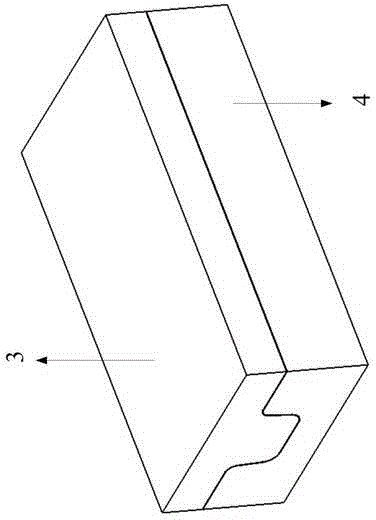

[0024] In Embodiment 1, as attached figure 1 Shown is a forming method for the smooth transition of properties in different regions of high-strength steel hot-formed parts. In this embodiment, boron-containing hot-stamped steel is used, and the plate thickness is 0.5-3.0mm uniform plate, and the delivery state is annealed. The chemical composition is shown in Table 1.

[0025] Table 1 Chemical composition of boron-containing steel (wt, %)

[0026]

[0027] Specifically include the following steps:

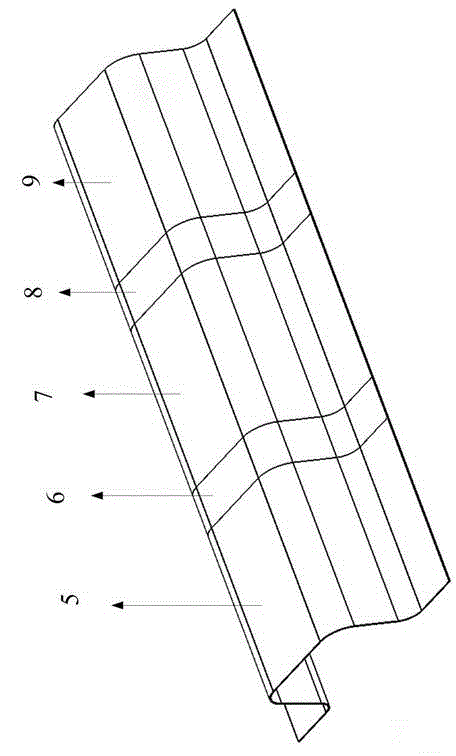

[0028] Step A, determining the positions of the impact energy-absorbing areas (5, 9) and the position of the high-strength area 7 of the formed sheet 1 according to the strength requirement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com