Computer simulation method for casting property of particle-reinforced aluminum matrix composite

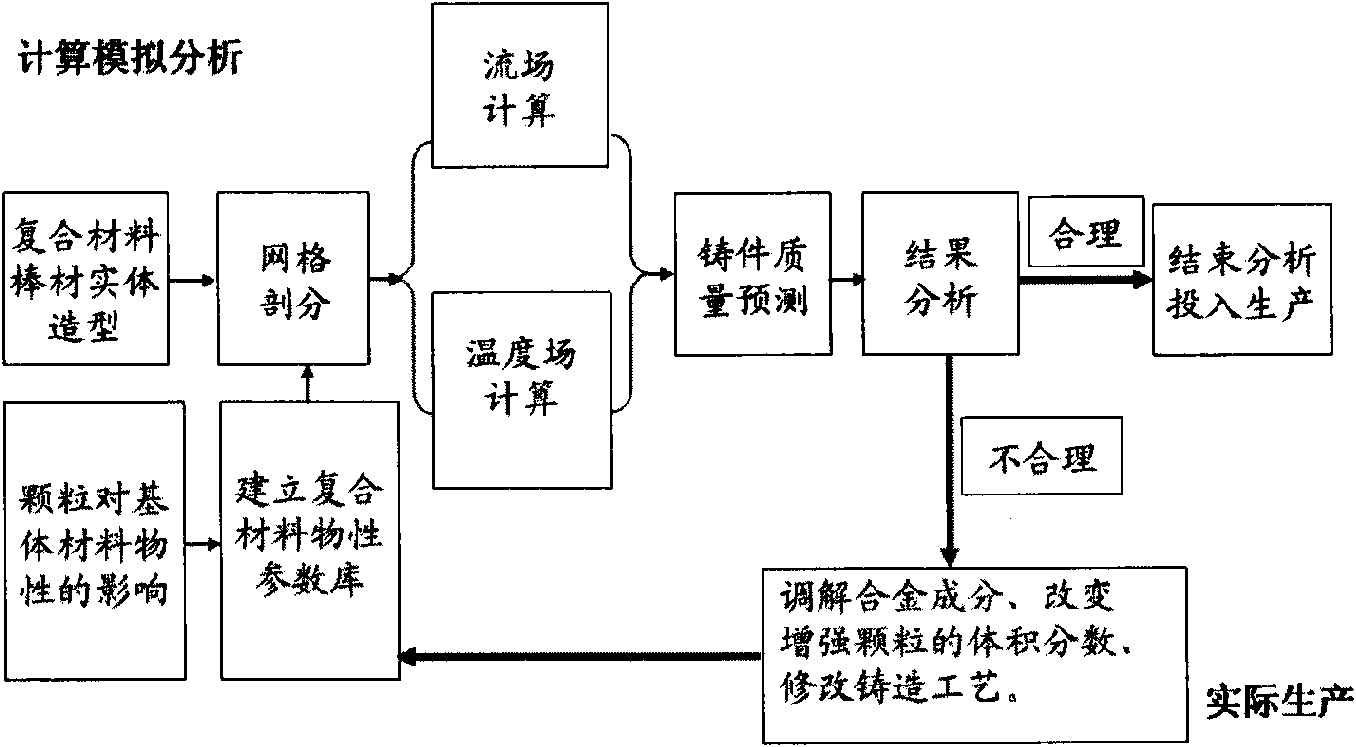

A particle-reinforced aluminum and composite material technology, applied in computing, special data processing applications, instruments, etc., to optimize the casting process, eliminate casting defects, and shorten the development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in conjunction with a research example of the casting performance of a particle-reinforced aluminum matrix composite motorcycle wheel.

[0050] 1) Determination of physical parameters of particle reinforced aluminum matrix composites

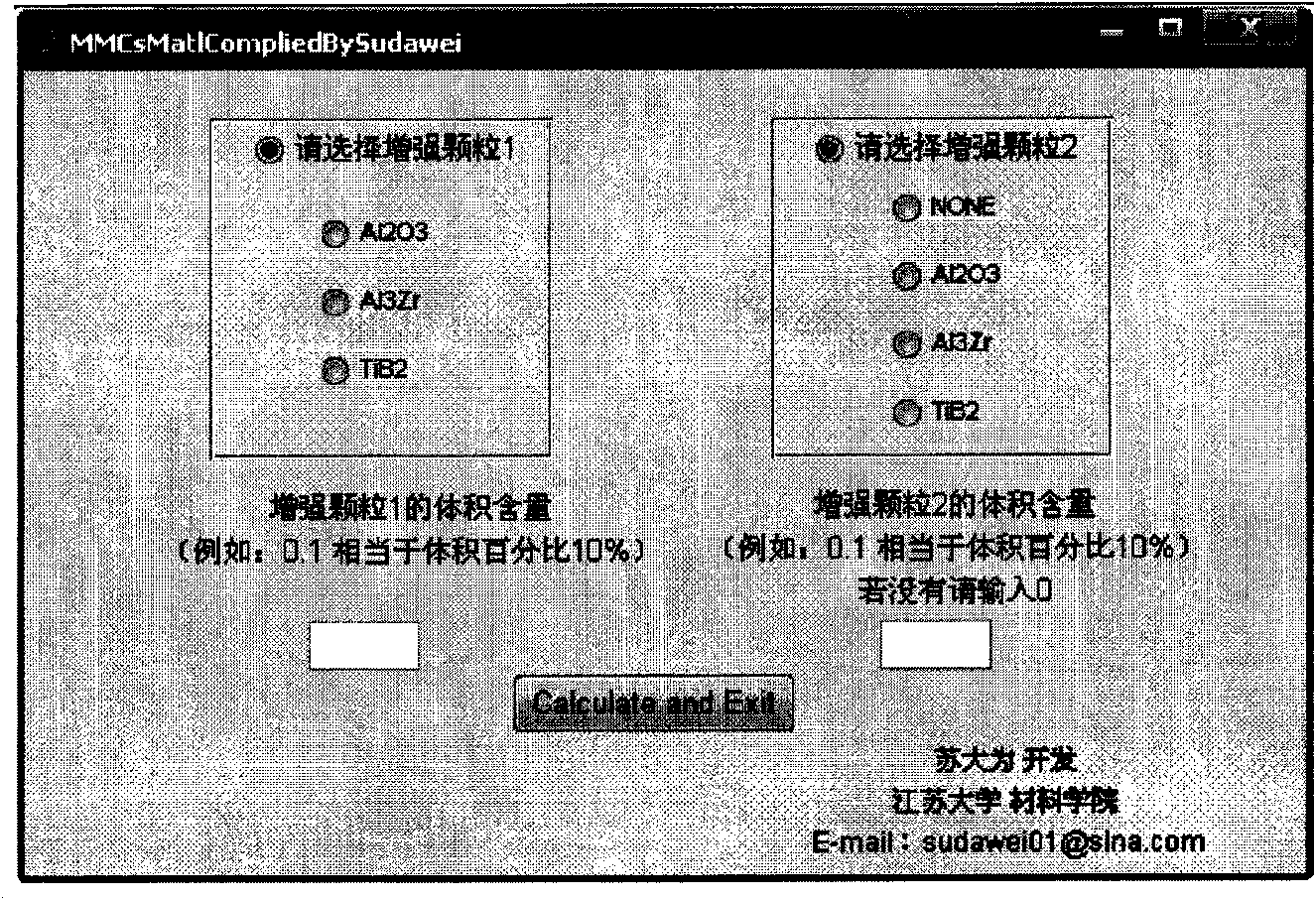

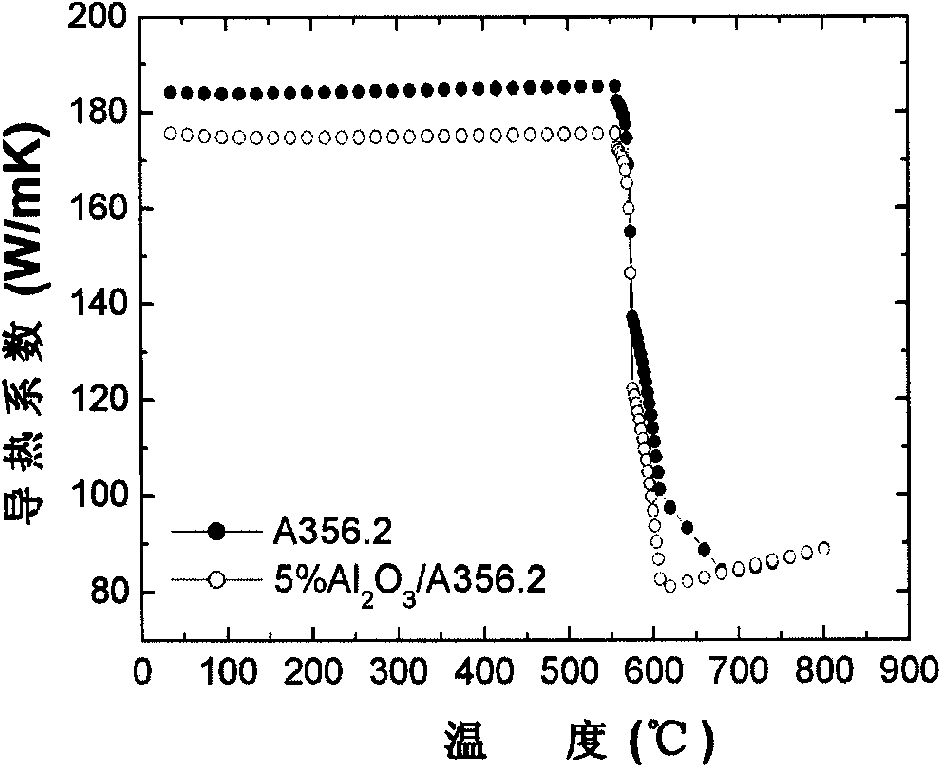

[0051] Taking the LMC499-2 type (15in×4.5in×9.76kg) motorcycle wheel of an aluminum industry as the object, the Al with a volume fraction of 5% was studied 2 o 3 Casting properties of particle reinforced A356.2 aluminum matrix composites. The mass fraction of the matrix A356.2 components is ω(Si)=7%, ω(Mg)=0.33%. The volume fraction of 5% Al is calculated by using the secondary developed metal matrix composite material performance calculation program 2 o 3 / A356.2 Numerical relationship between thermal conductivity, density, viscosity and temperature of composite materials, such as image 3 Shown in the solid line, and compared with the thermal conductivity, density, and viscosity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com