Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Excellent high temperature wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant and wear-resistant hard alloy and preparation method thereof

ActiveCN102978499AGuaranteed temperatureEnsure that the temperature of the powder does not exceed the temperatureHydrogen atmosphereWear resistant

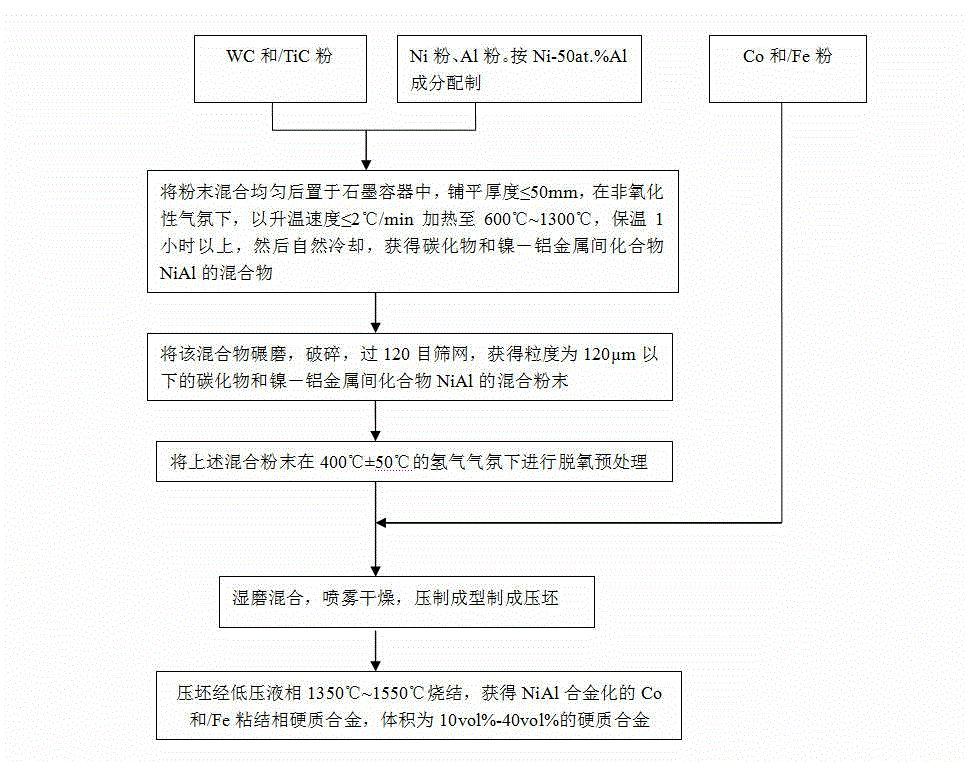

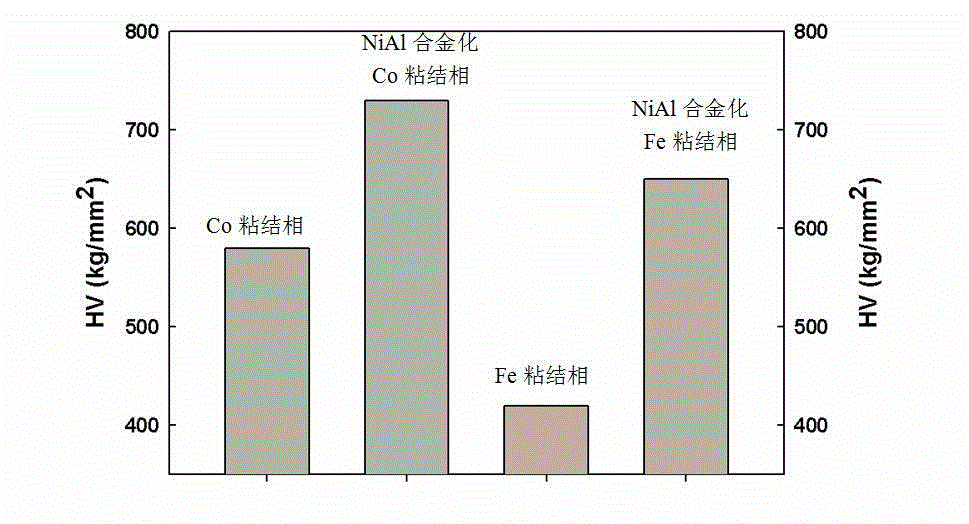

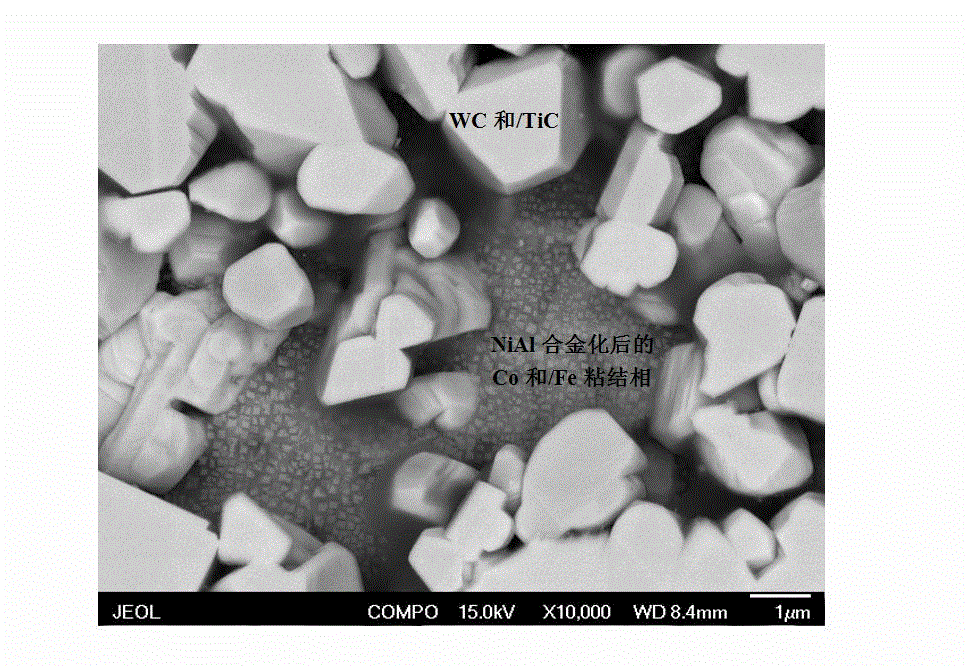

The invention discloses a high-temperature-resistant and wear-resistant hard alloy with a NiAl alloying bonding phase. WC and / TiC is used as a hard phase, NiAl alloying Co and / Fe is used as a bonding phase, and the volume ratio of the hard phase to the bonding phase is equal to 10-40%. The preparation method comprises the following steps of: uniformly mixing 0.03-21.04wt% of nickel powder and aluminum powder with carbide powder based on the component proportion of Ni-50at.%Al; placing the mixture in a graphite container to spread out, heating the mixture to 660-1300 DEG C at a non-oxidative atmosphere, preserving heat, and then naturally cooling to obtain a mixture of a carbide and NiAl; grinding, crushing and screening to obtain mixed powder; carrying out deoxidation pretreatment at a hydrogen atmosphere of 400+ / -50 DEG C; carrying out wet grinding on 45.77-96.34wt% of mixed powder and the balance of Co and / Fe powder; carrying out spray-drying on the mixed material subjected to wet grinding and pressing; and sintering a compaction in a liquid phase at low pressure at the temperature of 1350-1550 DEG C to obtain the high-temperature-resistant and wear-resistant hard alloy.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

High-temperature wear-resisting and corrosion-resisting steel powder for additive manufacturing and additive manufacturing method

ActiveCN105886923AExcellent high temperature wear resistanceImprove temper stabilityAdditive manufacturing apparatusIncreasing energy efficiencyAdditive layer manufacturingLaser

The invention discloses high-temperature wear-resisting and corrosion-resisting steel powder for additive manufacturing. The high-temperature wear-resisting and corrosion-resisting steel powder is prepared from the following elements in percentage by weight: 0.1 to 0.3 weight percent of C, 1.0 to 1.5 weight percent of Mn, 0.2 to 0.6 weight percent of Si, 5 to 9 weight percent of Cr, 2.0 to 6.0 weight percent of Ni, 1.0 to 1.5 weight percent of Mo, 0.2 to 0.4 weight percent of V, 0.3 to 0.7 weight percent of Nb, and the balance of Fe, wherein the sum of mass percent of all the elements is 100 percent. A method for additive manufacturing by using the steel powder comprises the following steps of putting the steel powder into additive manufacturing equipment; partitioning a part to be manufactured and setting laser process parameters: output power is 200 to 400W, the spot diameter is 0.06 to 0.1mm, the scanning speed is 960 to 1500mm / s, and track pitch is 0.06 to 1.2mm; then importing partitioned programs into the additive manufacturing equipment; filling the additive manufacturing equipment with high-purity argon; finally, printing layer by layer, and obtaining a high-temperature wear-resisting and corrosion-resisting steel part at last.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Manufacture method of multilayer gradient nano-composite diamond film of surface of die steel

ActiveCN103160781AImprove bindingOvercome stressVacuum evaporation coatingSputtering coatingGas phaseBinding force

The invention discloses a manufacture method of a multilayer gradient nano-composite diamond film of the surface of die steel. The manufacture method includes that a plunger undergoing conventional pretreatment is arranged in a vacuum system of a magnetron sputtering composite vapor deposition system, and multiple layers of gradient films are sequentially deposited. Each layer of the multiple gradient transition layers undergoes high-temperature annealing treatment and argon ion surface etching treatment so as to improve binding force of the films and a base. The defects of high internal stress and poor adhesive force and the like of a conventional diamond film on the surface of the mold steel are overcome.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Manufacturing method of metal ceramic coating crystallizer copper plate

The invention provides a manufacturing method of metal ceramic coating crystallizer copper plate, belonging to the technical field of continuous casting crystallizer. The invention comprises the following steps: firstly pretreating the surface of the base material; carrying out purifying treatment on the surface of to-be-sprayed workpieces with acetone; carrying out sand spraying and roughening process with 20 meshes of brown aluminium oxide; then adopting the supersonic flame spraying method to spray Cr3C2-25NiCr metal ceramic coating on the surface of a copper crystallizer, coating a layer of brazing filler metal with low melting point mixed with metal ceramics on the metal ceramic coating; finally carrying out remelting treatment in a vacuum furnace, preserving heat for 0.5-2 hours at the temperature of 600 DEG C to 700 DEG C, and cooling to the room temperature by blowing high-pressured nitrogen. The invention has the advantages of ensuring the bonding intensity between the metal ceramic coating and the substrate, lowering the porosity of the coating, and improving the cohesion strength of the coating; the invention further has the advantages of even and compact coating, flat surface, realization of metallurgical bonding with the substrate, good properties of high temperature abrasion resistance and corrosion resistance, and good cold fatigue and hot fatigue resistance properties; the coating can bear the high temperature abrasion of the casting blank surface and the casting blank has lower friction coefficient, thus being beneficial for improving the quality of the casting blank surface and improving the speed of jolleying.

Owner:SHOUGANG CORPORATION

Preparation method of high-temperature anti-wear Fe-Cr-B-Al alloy

InactiveCN104164668AHigh hardnessHigh strengthMetallic material coating processesAl powderIron powder

The invention discloses a preparation method of a high-temperature anti-wear Fe-Cr-B-Al alloy and belongs to the technical field of wear-resistant materials. The alloy is prepared by adopting a laser cladding process. The preparation method comprises the following steps: firstly, uniformly mixing 12.0wt%-15.0wt% of low-carbon Cr-Fe powder, 12.0wt%-15.0wt% of high-carbon Cr-Fe powder, 6.0wt%-8.0wt% of B-Fe powder, 5.0wt%-6.0wt% of metal Al powder, 1.5wt%-2.0wt% of re-Si-Fe powder, 4.0wt%-5.0wt% of Fe2O3 powder and 52wt%-57wt% of pure Fe powder, wherein the particle size of the powder is within a range of 100-160 meshes; and secondly, inputting heat by adopting an optical fiber laser device, and feeding the powder materials by adopting a laser cladding synchronous powder feeder to obtain the Fe-Cr-B-Al alloy which is high in hardness and good in high-temperature wear resistance, wherein in the cladding process, the powder feeding rate is 15-20g / min, the laser power is 1500-2500W, and the scanning speed is 3-8mm / s.

Owner:BEIJING UNIV OF TECH

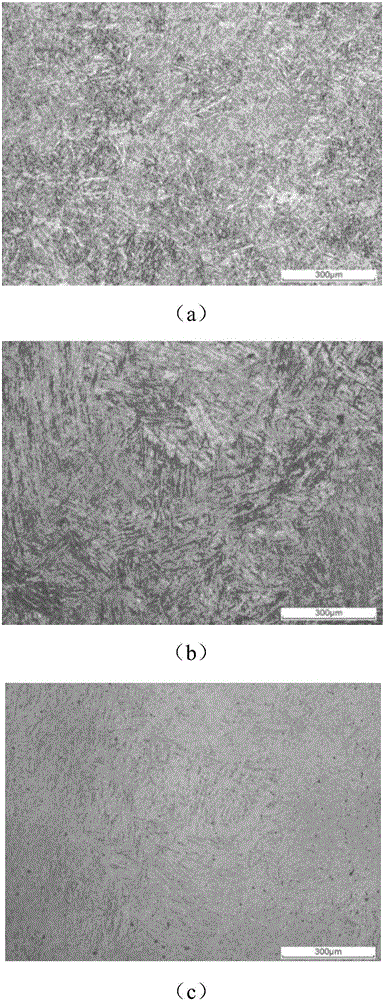

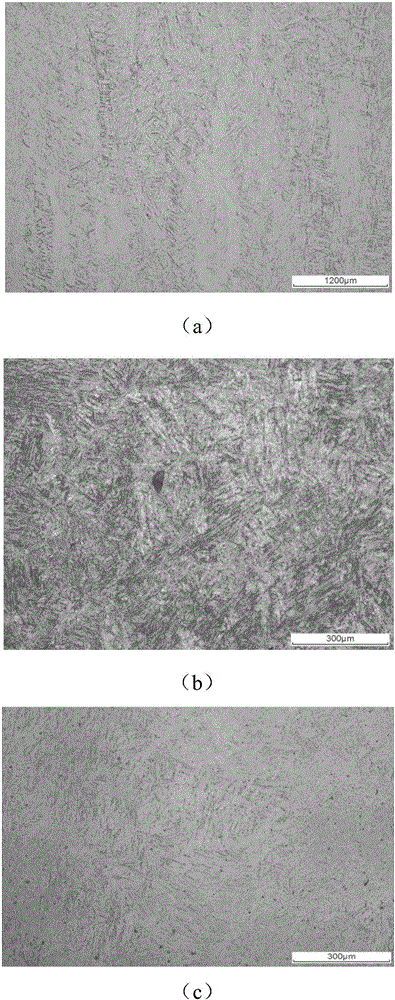

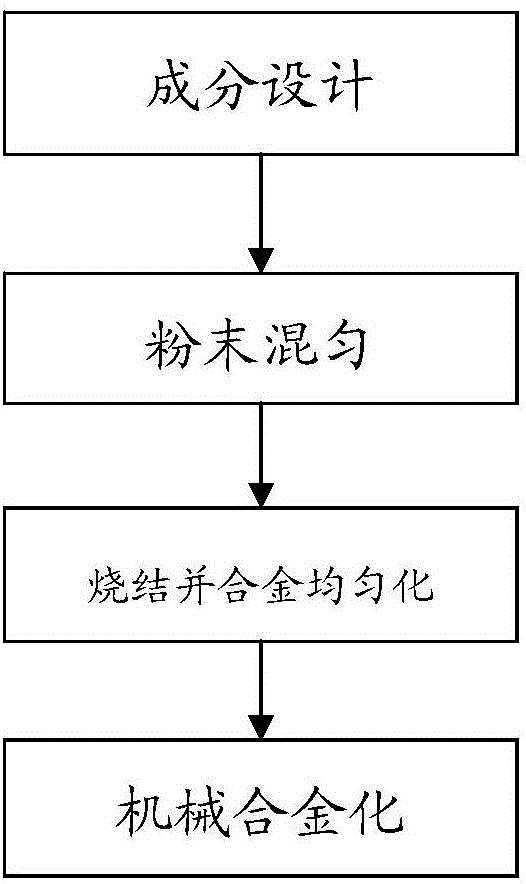

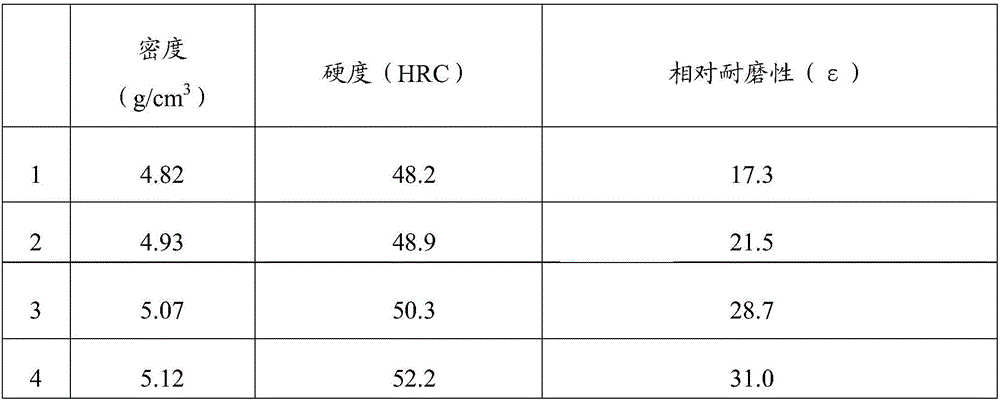

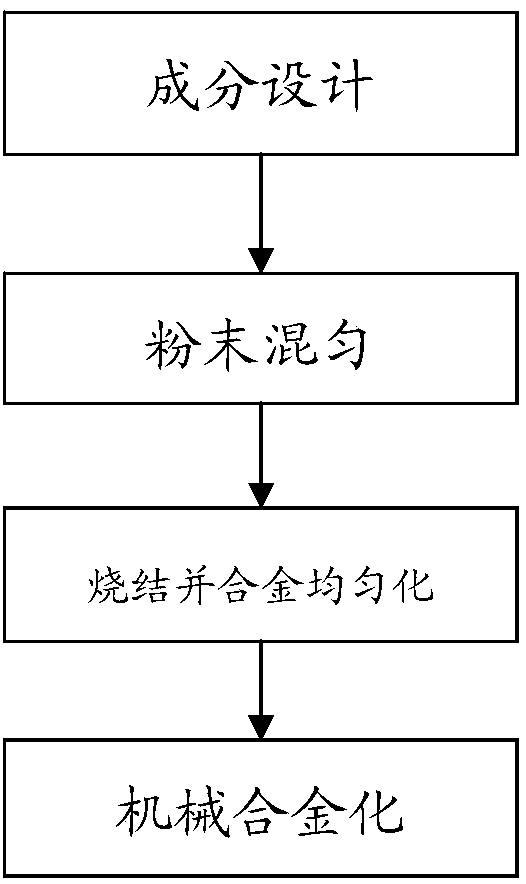

Titanium-based tungstenic alloy material used for 3D printing and preparation method thereof

ActiveCN106756240AHigh temperature hardnessExcellent high temperature wear resistanceAdditive manufacturing apparatusCorrosionHardness

The invention discloses a titanium-based tungstenic alloy material used for 3D printing. The material contains tungsten carbide, nickel, niobium, vanadium, copper, molybdenum and titanium. A preparation method comprises the steps that metal powder is fully mixed after component design is completed; the mixed powder is subjected to sintering and alloy homogenizing; and then alloy powder is obtained through mechanical alloying. A 3D printing finished product of the obtained material has the advantages of being low in weight, high in high-temperature hardness, excellent in high-temperature abrasion resistance, and resistant to corrosion.

Owner:康硕电气集团有限公司

Sink roll shaft sleeve

InactiveCN104294183AImprove mechanical propertiesImprove toughnessHot-dipping/immersion processesProcess efficiency improvementNiobiumTitanium

The invention discloses a sink roll shaft sleeve which is composed of 0.24%-0.45% of C, 0.60%-2.0% of Mn, 0.80%-1.10% of Si, 0.02%-0.12% of Zr, 0.035%-0.080% of Al, 2.7%-3.5% of Cr, 0.75%-1.60% of Ni, 0.02%-0.03% of Y, 0.5%-2.5% of Mo, 0.03%-0.55% of Nb, 2.5%-3.3% of B, 0.003%-0.01% of N, less than 0.035% of P, less than 0.045% of S and the balance of Fe. By adding the boron element on the basis of the low-carbon high-speed steel, the sink roll shaft sleeve has excellent liquid zinc corrosion resistance on the premise of keeping favorable high-temperature red hardness of the high-speed steel. Besides, proper amounts of yttrium, magnesium, calcium, titanium, niobium and potassium are also added to mainly perform the functions of removing oxygen and sulfur, refining the structure and improving the inclusion morphology and distribution, thereby being beneficial to enhancing the mechanical properties of the sink roll shaft sleeve and especially the obdurability of the sink roll shaft sleeve.

Owner:JIANGSU HUAYE TECH

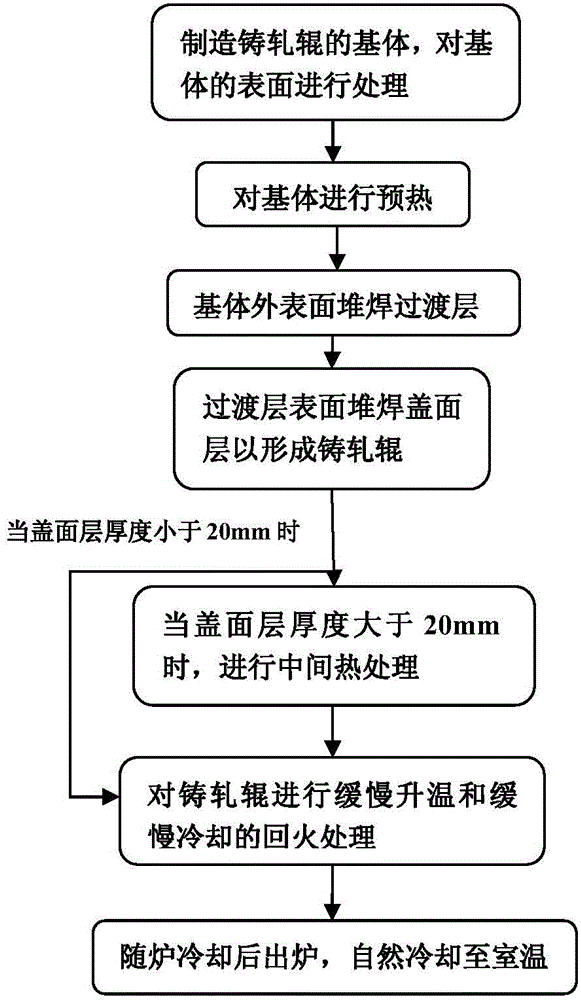

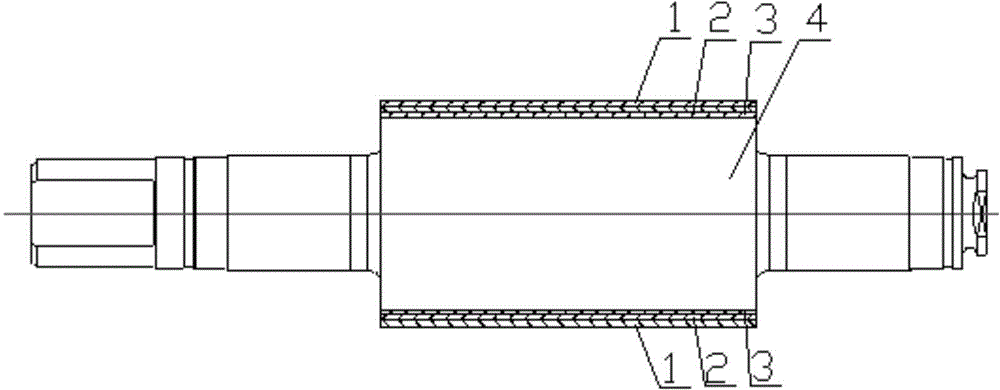

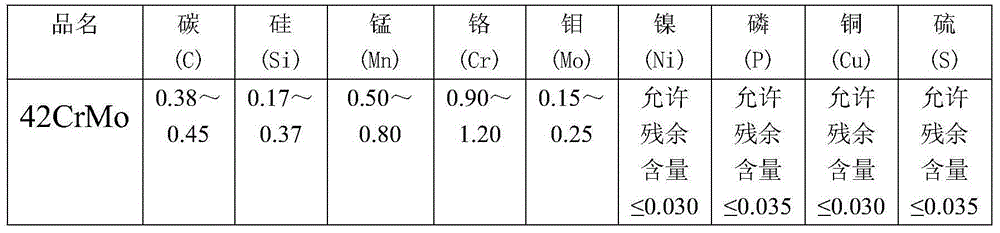

Composite overlaying manufacturing method of casting roller

InactiveCN104416293AEasy to implementEasy to operateArc welding apparatusRare-earth elementMetallurgy

The invention discloses a composite overlaying manufacturing method of a casting roller. The method comprises the steps of 1) manufacturing a base body of the casting roller, and processing the surface of the base body; 2) preheating the base body; 3) sequentially manufacturing a bottom layer and a transition layer in the periphery of the base body by overlaying; 4) overlaying surface covering layer on the surface of the transition layer to form the casting roller, wherein the surface covering layer comprises the following chemical elements and components in percentage by mass: 0.3 to 0.8% of C, 1.0 to 4.8% of Mn, 0.4 to 6.0% of Si, 4.0 to 8.0% of Cr, 0.01 to 1.0% of Ti, 2.0 to 10% of V, 2.0 to 10.0% of W, 1.0 to 6.0% of Mo, 2.0 to 5.0% of Co, 0 to 0.4% of Ca, 0 to 0.4% of Ba, 0 to 0.5% of rare earth element, and the balance of Fe and other inevitable impurities; 5) tempering the casting roller by slowly heating and slowly cooling, wherein the tempering is performed under a temperature of 560 to 600 DEG C.

Owner:中冶东方工程技术有限公司秦皇岛研究设计院 +1

Method for preparing reinforced molybdenum alloy

The invention discloses a preparing method of strengthening molybdenum alloy of pressing mould, inlaid and squeezing mould of copper, other alloys and black metal, which is characterized by the following: adopting TiC as strengthening phase of molybdenum alloy; adding Ti at TiO2 pattern and carbon at carbon black pattern; reducing TiO2 into TiC under high temperature; obtaining the product with high-temperature strength and superior high-temperature abrasion-proof property.

Owner:JINDUICHENG MOLYBDENUM CO LTD

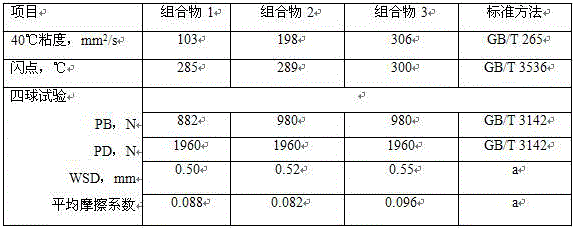

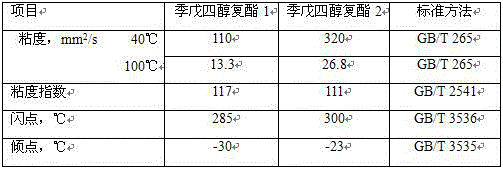

Chain oil composition with excellent high temperature abrasion resistance

InactiveCN105419910AHigh flash pointHigh viscosity indexAdditivesBase-materialsDistillationPhosphate

The invention discloses a chain oil composition with excellent high temperature abrasion resistance. The composition is prepared from, by mass, 92%-96% of dipentaerythritol ester, 1%-3% of antioxygen composition, 2%-4% of abrasion resisting agent composition, 0.2%-0.8% of corrosion inhibitor and 0.2%-0.6% of antirust agent. Dipentaerythritol ester is prepared through the steps that pentaerythritol, binary acid and unitary saturated fatty acid react for 12-16 h at the temperature of 160 DEG C to 200 DEG C at the presence of a catalyst, and then reduced pressure distillation, hargil adsorption and filtering are carried out. The antioxygen composition is a composition of diphenylamine antioxygen, naphthylamine antioxygen and an amine antioxygen oligomer. The abrasion resisting agent composition is a composition of phosphite ester, phosphate and dialkyl dithiocarbamic acid molybdenum. Dipentaerythritol ester is adopted as base oil of chain oil, and the advantages of being high in flash point, low in frequency point, high in viscosity index, low in evaporation loss, not likely to coke and the like are achieved. Dipentaerythritol ester is reasonably compounded with an additive, and the high-temperature chain oil composition with the excellent high temperature abrasion resistance is obtained.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-temperature antifriction metal

The invention discloses an alloy with resistance to wear under high temperature, and relates to an alloy. The objective of the invention is provided with an alloy with resistance to wear under high temperature, having good resistance to wear under high temperature and long service life. The inventive technical protocol is that, each composition of an alloy with resistance to wear under high temperature and weight percents: C 0.13-0.28%, Si 0.5-2.2% Mn 0.7-1.6%, P <=0.04%, S <=0.03%, Cr 21-25%, Ni 6-8%, Mo 0.8-1.2%, V 0.4-0.7%, N 0.15-0.3%, Re 0.6-0.8%, and the residuel of Fe. The invention is usable for outlet guard iron and central cylinder.

Owner:HENAN HONGYU SPECIAL CASTINGS

Preparation method of complexly-modified high-speed steel roll

The invention discloses a preparation method of a complexly-modified high-speed steel roll, and belongs to the technical field of steel rolling. A high-speed steel roll material is smelted in a medium-frequency induction furnace, and molten steel in the furnace is controlled to be prepared from the chemical compositions in percentage by mass: 2.32-2.49% of C, 4.17-4.33% of W, 4.80-4.98% of Mo, 9.63-9.85% of Cr, 0.48-0.66% of Mn, 0.57-0.81% of Si, less than 0.035% of S, less than 0.040% of P and the balance of Fe; and then the molten steel is heated to 1615-1626 DEG C, aluminum is added after heat preservation is conducted for 4-5 min, then modification treatment is conducted through a wire feeding method, the molten steel is poured into a casting mold rotating at a high speed on a centrifugal machine, after the high-speed steel is solidified, ductile iron is used for core filling in a static state, and the high-speed steel roll excellent in performance and good in using effect can be obtained through quenching and tempering treatment.

Owner:安徽环渤湾高速钢轧辊有限公司

Process for performing laser cladding of superhard high speed steel by hot rolling of stretch reducing roller of seamless steel pipe

ActiveCN104250802AHigh hardnessGood metallurgyMetallic material coating processesMelting tankBroadband

The invention relates to a process for performing laser cladding of a superhard high speed steel by hot rolling of a stretch reducing roller of a seamless steel pipe, which is characterized by comprising the following steps: removing oil and rust on the surface of the stretch reducing roller, washing by alcohol, labeling by partitioning a processing area; preparing the superhard high speed steel powder alloy powder, adjusting an automatic powder feeding apparatus so that the alloy powder from an automatic powder feeding head can just fall in a laser molten pool, adjusting the powder feeding amount; selecting a 3.5*1mm broadband integration mirror, and adjusting defocusing amount to make a focused laser spot as an rectangular shape, employing a synchronization powder feeding apparatus for automatically seeding the alloy powder into a laser molten pool, forming an uniform and compact laser cladding layer on the surface; cladding and then performing flaw detection examination, then performing thermal treatment on the stretch reducing roller. The selected superhard high speed steel powder and the stretch reducing roller matrix have good metallurgy and mechanical compatibility, the cladding layer and the matrix can form firm metallurgy combination, hardness is high, thickness is uniform, and crack and spalling phenomena can not be generated.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Sink roller shaft sleeve

InactiveCN107630168AImprove mechanical propertiesImprove toughnessHot-dipping/immersion processesFurnace typesNiobiumPotassium

The invention discloses a sink roller shaft sleeve. The sink roller shaft sleeve comprises 0.24-0.45% of C, 0.60-2.0% of Mn, 0.80-1.10% of Si, 0.02-0.12% of Zr, 0.035-0.080% of Al, 2.7-3.5% of Cr, 0.75-1.60% of Ni, 0.02-0.03% of Y, 0.5-2.5% of Mo, 0.03-0.55% of Nb, 2.5-3.3% of B, 0.003-0.01% of N, less than 0.035% of P, less than 0.045% of S, and the balance Fe. On the basis of arranging the sinkroller shaft sleeve on low-carbon high-speed steel in a sleeving mode, the boron element is added, and under the premise that the high-speed steel has excellent high-temperature red hardness, the sinkroller shaft sleeve has excellent zinc liquid corrosion resistance; and in addition, the appropriate amount of yttrium, magnesium, calcium, titanium, niobium and potassium are added, the functions ofdeoxidation, desulfurization, texture refining and morphology and distribution of inclusions improving are mainly achieved, the mechanical property of the sink roller shaft sleeve is advantageously improved, and especially the properties of strength and toughness of the sink roller shaft sleeve are improved.

Owner:王茂庭

Novel alloy material used for electric heater

InactiveCN107805732AImprove thermal conductivityExcellent high temperature wear resistanceHeating element materialsChemical compositionCompound (substance)

The invention relates to a high strength and high conductivity heat-resisting copper alloy and a manufacturing method thereof, and discloses a novel alloy material used for an electric heater. The novel alloy material has good thermal conductivity and high temperature abrasion resistance, and meanwhile, the novel alloy material has the high high-temperature strength and hardness as well as the very good elongation. The novel alloy material comprises the chemical compositions of, by weight, 0.3-1.1% of Cr, 0.05-0.4% of Zr, 0.06-0.12% of W, 0.03-0.11% of V, 0.04-0.1% of Nb, 0.02-0.05% of Mg, 0.02-0.07% of Ce, 0.02-0.05% of Y, and the balance Cu.

Owner:JIANGSU DOUSHENG TECH DEV CO LTD

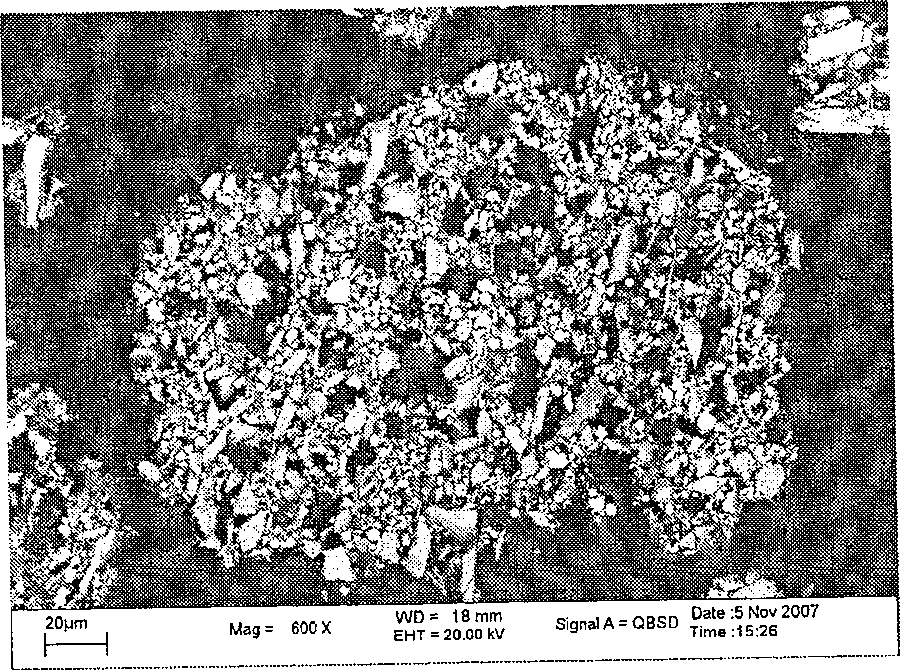

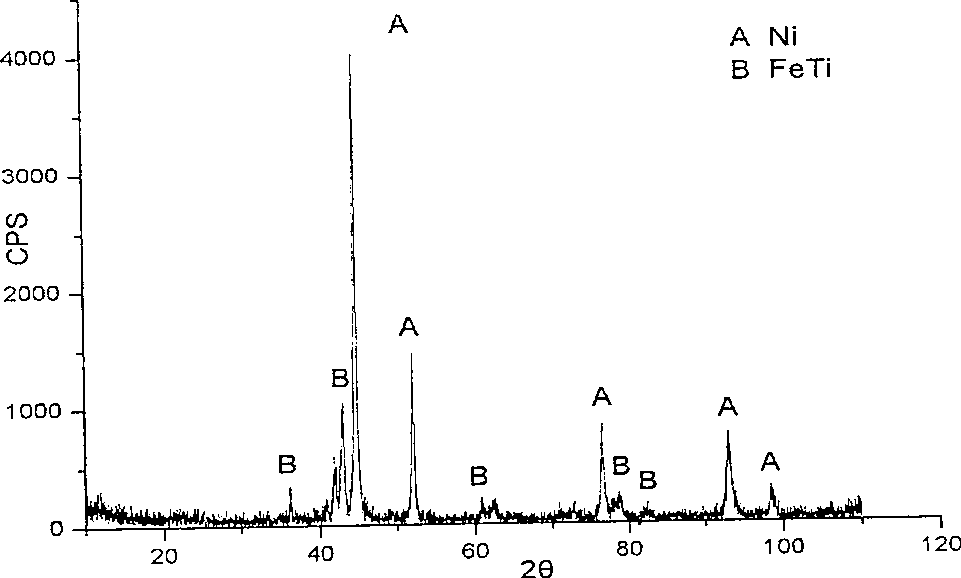

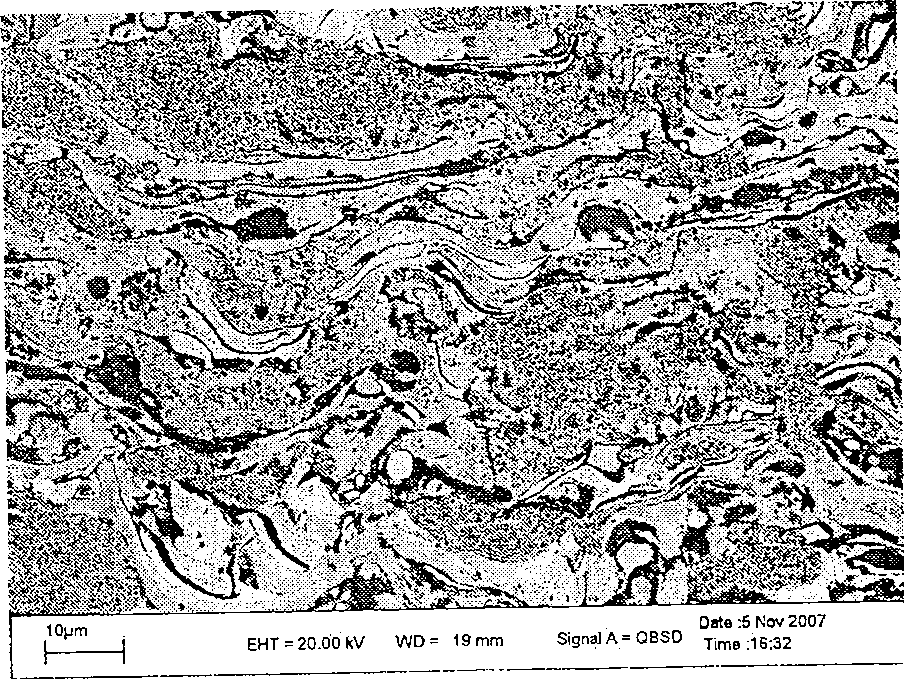

Ti-Fe-Ni-C series reaction thermal spraying composite powder and preparation technique thereof

InactiveCN100510155CHigh bonding strengthAvoid easy separationMolten spray coatingPorosityThermal spraying

The present invention is one kind of composite hot sprayed Ti-Fe-Ni-C powder capable of forming composite TiC / Fe-Ni alloy coating and its preparation process. The composite Ti-Fe-Ni-C powder containing Ni in the amount of 32-45 wt% of Fe+Ni content and Ti+C in over 70 wt% is prepared with sucrose as the precursor of C. The TiC / Fe-Ni alloy coating formed through hot spraying with Fe-Ni alloy as the adhering phase has the advantages of small stress, low porosity, high bonding strength between the Fe-Ni alloy and TiC, excellent high temperature antiwear and anticorrosion performance and small TiC grain size.

Owner:UNIV OF SCI & TECH BEIJING

A process method of laser cladding superhard high-speed steel for hot-rolled seamless steel pipe stretching and reducing rolls

ActiveCN104250802BHigh hardnessGood compatibilityMetallic material coating processesMelting tankBroadband

The invention relates to a process for performing laser cladding of a superhard high speed steel by hot rolling of a stretch reducing roller of a seamless steel pipe, which is characterized by comprising the following steps: removing oil and rust on the surface of the stretch reducing roller, washing by alcohol, labeling by partitioning a processing area; preparing the superhard high speed steel powder alloy powder, adjusting an automatic powder feeding apparatus so that the alloy powder from an automatic powder feeding head can just fall in a laser molten pool, adjusting the powder feeding amount; selecting a 3.5*1mm broadband integration mirror, and adjusting defocusing amount to make a focused laser spot as an rectangular shape, employing a synchronization powder feeding apparatus for automatically seeding the alloy powder into a laser molten pool, forming an uniform and compact laser cladding layer on the surface; cladding and then performing flaw detection examination, then performing thermal treatment on the stretch reducing roller. The selected superhard high speed steel powder and the stretch reducing roller matrix have good metallurgy and mechanical compatibility, the cladding layer and the matrix can form firm metallurgy combination, hardness is high, thickness is uniform, and crack and spalling phenomena can not be generated.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

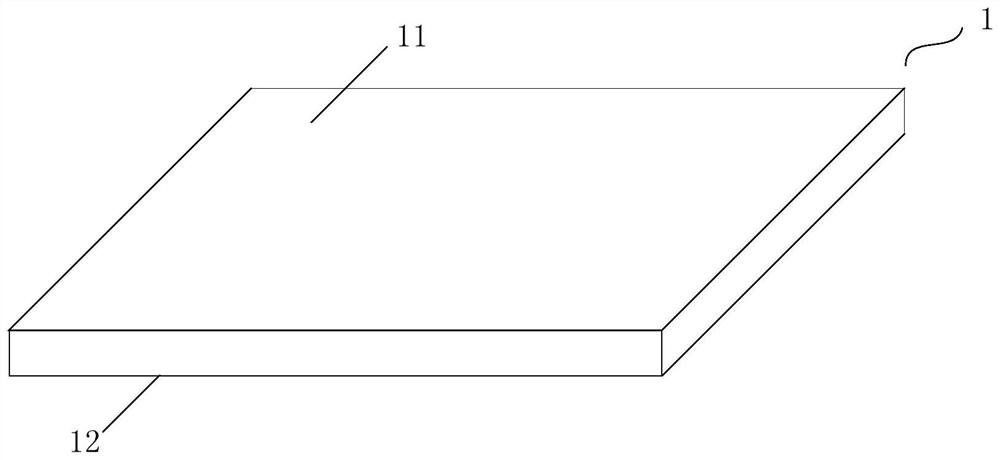

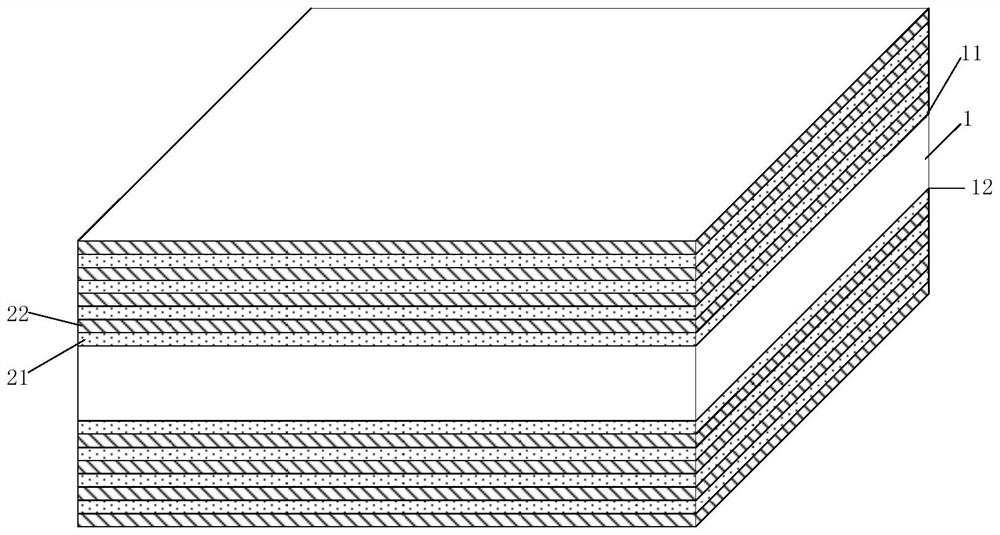

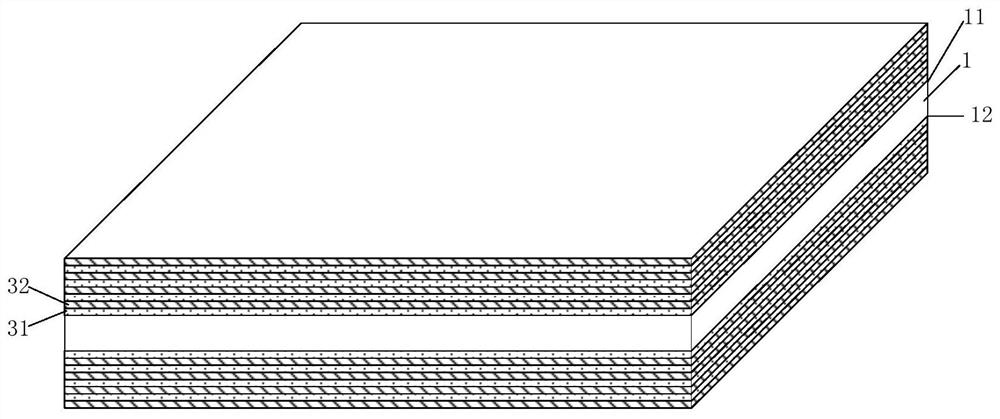

High-temperature corrosion-resistant push plate of garbage incinerator and preparation method thereof

PendingCN111850551AExcellent high temperature wear resistanceExtended service periodMetallic material coating processesIncinerator apparatusHigh densityIncineration

The invention belongs to the technical field of surface engineering and relates to a high-temperature corrosion-resistant push plate of a garbage incinerator. The push plate comprises a push plate matrix, and TiC / Fe-Al2O3 high density ceramic-based composite material coatings cladded to the upper and lower surfaces of the push plate. The TiC / Fe-Al2O3 high density ceramic-based composite material coating is formed by cladding a Fe-Al2O3 ceramic-based composite material layer and a TiC metal ceramic layer as coating materials to the upper and lower surfaces of the push plate layer by layer alternately successively. The push plate has excellent high-temperature corrosion resistance, can meet severe service conditions in the garbage incinerator and is long in service life. The invention further relates to a preparation method of the high-temperature corrosion-resistant push plate of the garbage incinerator. The method is simple in process and low in cost and can manufacture the high-temperature corrosion-resistant push plate quickly at one time. The method has the advantages of being energy-saving, quick, efficient and the like.

Owner:JIANGSU KEHUAN INNOVATIVE MATERIAL CO LTD +1

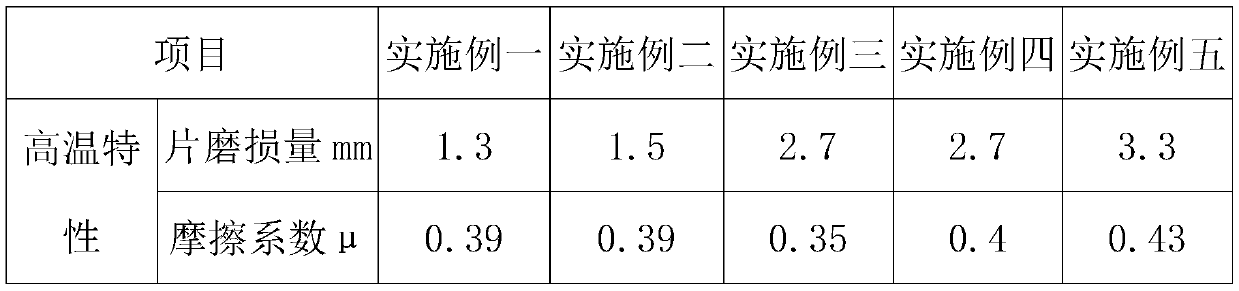

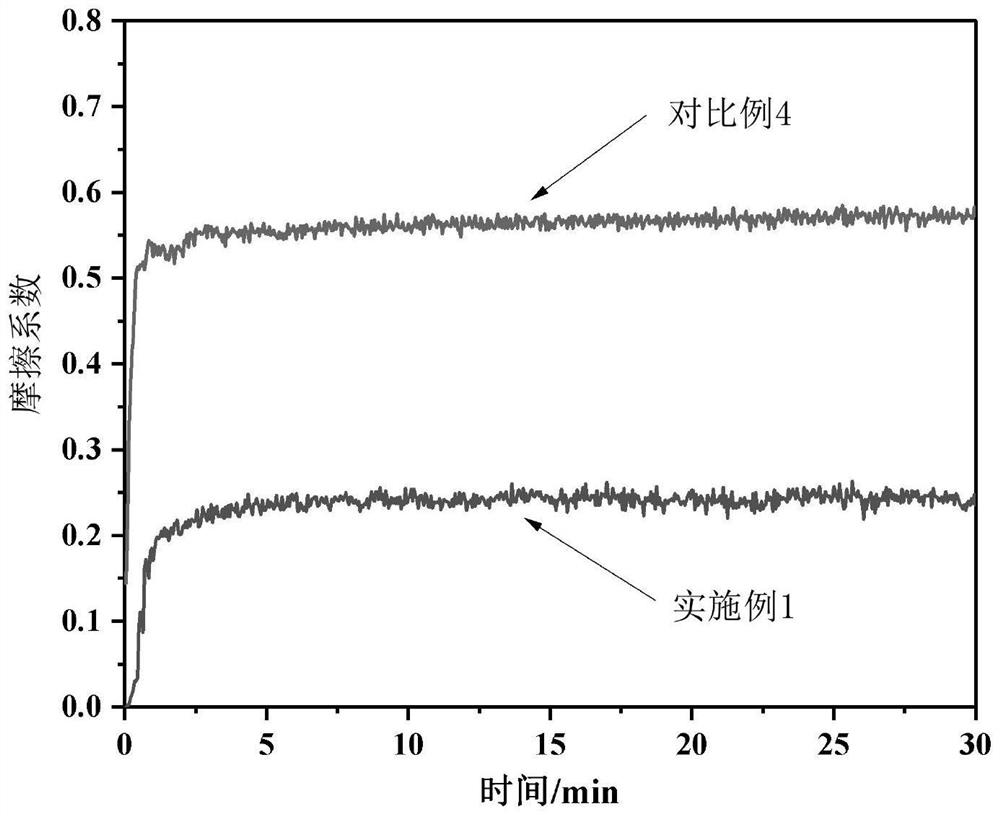

High-temperature 500-degrees centigrade abrasion-resistant brake pad and preparation method thereof

InactiveCN111561530AStable coefficient of frictionModerate hardnessBraking membersFriction liningCarbon compositesAramid

The invention relates to the technical field of vehicle brakes, in particular to a high-temperature 500-degrees centigrade abrasion-resistant brake pad used for solving the technical problems that a brake pad is high in brake potential safety hazards in a high-speed traveling high-temperature status, meanwhile, abrasion is severe, and the service life is shortened. The brake pad comprises the following raw materials including, by weight, 10-20% of flaky titanium potassium lithium, 5-15% of zirconia, 7-10% of resin, 3-5% of copper fiber, 4-6% of mineral fiber, 2-5% of frictional powder, 1-3% ofrubber powder, 2-5% of aramid fiber, 3-5% of tin sulfide, 3-8% of carbon composite, 3-7% of calcium hydroxide, 2-4% of mica powder and the balance being barium sulfate. According to the brake pad provided by the invention, the new materials of flaky titanium potassium lithium and the zirconia are added to improve the friction material, the friction material is made to have better high-temperatureabrasion resistance, and the service life of the brake pad is greatly prolonged.

Owner:浙江万赛汽车零部件股份有限公司

High-temperature wear-resistant and corrosion-resistant steel powder for additive manufacturing and additive manufacturing method

ActiveCN105886923BExcellent high temperature wear resistanceImprove temper stabilityAdditive manufacturing apparatusIncreasing energy efficiencyHigh-temperature corrosionAdditive layer manufacturing

The invention discloses a high-temperature wear-resistant and corrosion-resistant steel powder for additive manufacturing, which contains the following elements in mass percent: C 0.1-0.3% Wt., Mn 1.0-1.5% Wt., Si 0.2-0.6% Wt ., Cr 5~9%Wt., Ni 2.0~6.0%Wt., Mo 1.0~1.5%Wt., V 0.2~0.4%Wt., Nb 0.3~0.7%Wt., the balance is Fe, the above elements The sum of the mass percentages is 100%. The method of using the steel powder for additive manufacturing is: put the above steel powder into the additive manufacturing equipment; divide the parts to be manufactured and set the laser process parameters as follows: output power 200-400W, spot diameter 0.06-0.1 mm, scanning speed 960-1500mm / s, track spacing 0.06-1.2mm; then import the subdivided program into the additive manufacturing equipment; fill the additive manufacturing equipment with high-purity argon, and finally print layer by layer, Finally, high-temperature wear-resistant and corrosion-resistant steel parts are obtained.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Manufacturing method of metal ceramic coating crystallizer copper plate

The invention provides a manufacturing method of metal ceramic coating crystallizer copper plate, belonging to the technical field of continuous casting crystallizer. The invention comprises the following steps: firstly pretreating the surface of the base material; carrying out purifying treatment on the surface of to-be-sprayed workpieces with acetone; carrying out sand spraying and roughening process with 20 meshes of brown aluminium oxide; then adopting the supersonic flame spraying method to spray Cr3C2-25NiCr metal ceramic coating on the surface of a copper crystallizer, coating a layer of brazing filler metal with low melting point mixed with metal ceramics on the metal ceramic coating; finally carrying out remelting treatment in a vacuum furnace, preserving heat for 0.5-2 hours at the temperature of 600 DEG C to 700 DEG C, and cooling to the room temperature by blowing high-pressured nitrogen. The invention has the advantages of ensuring the bonding intensity between the metal ceramic coating and the substrate, lowering the porosity of the coating, and improving the cohesion strength of the coating; the invention further has the advantages of even and compact coating, flat surface, realization of metallurgical bonding with the substrate, good properties of high temperature abrasion resistance and corrosion resistance, and good cold fatigue and hot fatigue resistance properties; the coating can bear the high temperature abrasion of the casting blank surface and the casting blank has lower friction coefficient, thus being beneficial for improving the quality of the casting blank surface and improving the speed of jolleying.

Owner:SHOUGANG CORPORATION

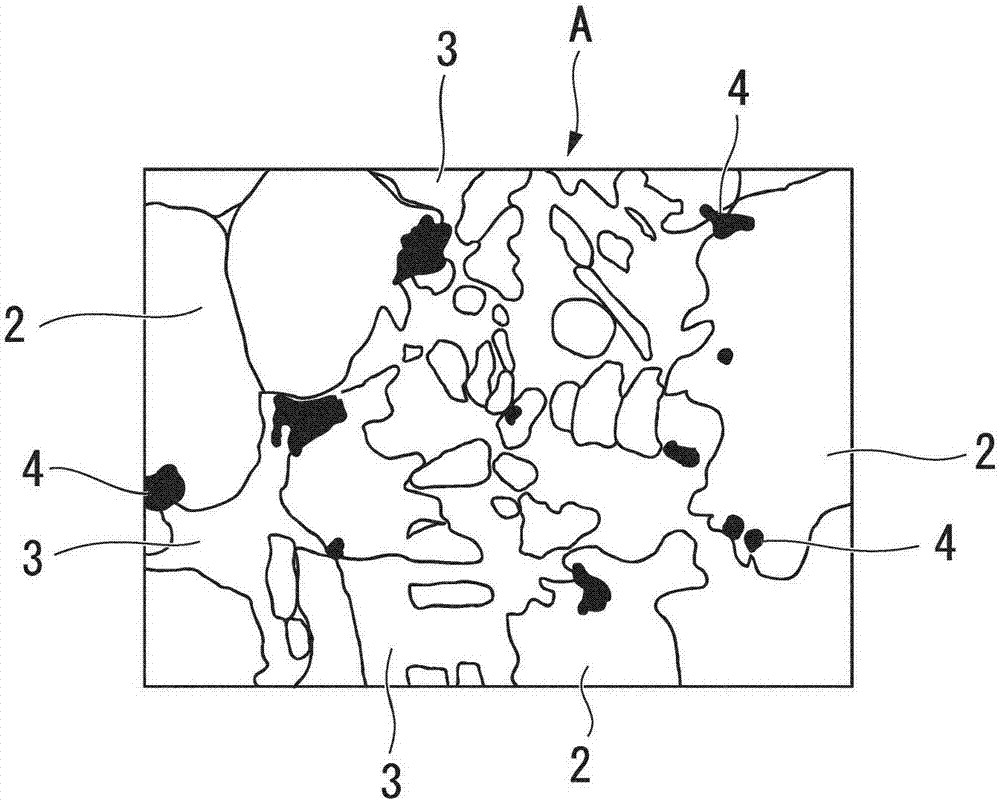

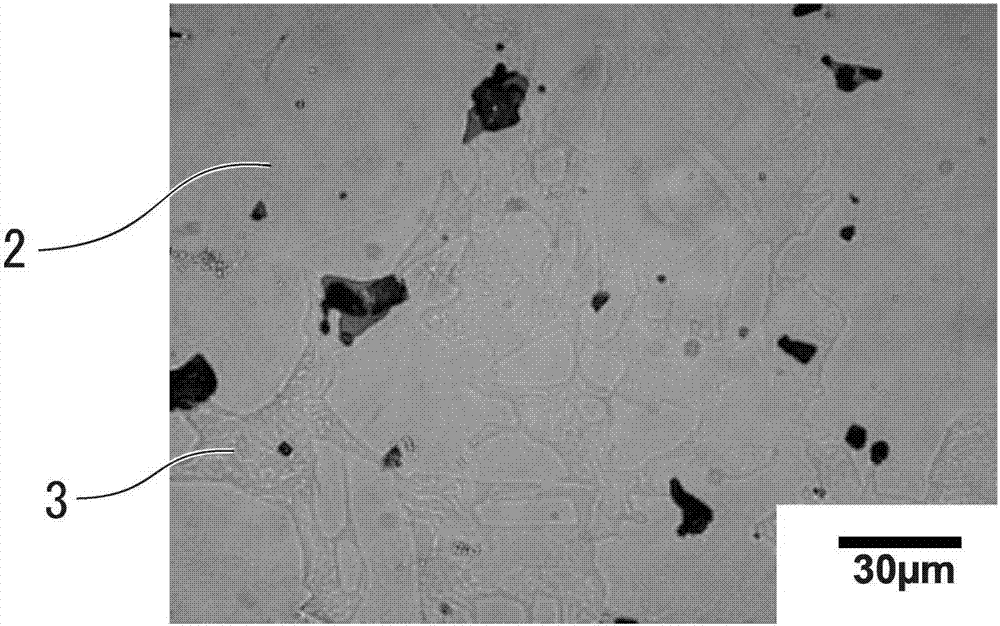

Heat-resistant sintered material having excellent oxidation resistance, wear resistance at high temperatures and salt damage resistance, and method for producing same

ActiveCN107429350AGood heat resistance and corrosion resistanceExcellent wear resistanceTurbinesOxidation resistanceWear resistance

The purpose of this heat-resistant sintered material and a production method thereof is to obtain a heat-resistant sintered material that has excellent oxidation resistance, wear resistance at high temperatures, and salt damage resistance. This heat-resistant sintered material is characterized by: having a composition that contains, in mass%, 25-50% of Cr, 2-25% of Ni and 0.2-1.2% of P, with the balance made up of Fe and unavoidable impurities; and having a structure that comprises an Fe-Cr matrix and hard phases that are dispersed within the Fe-Cr matrix and are composed of Cr-Fe alloy grains. This heat-resistant sintered material is also characterized in that: the Cr content in the Fe-Cr matrix is 24-41% by mass; the Cr content in the hard phases is 30-61% by mass; and the intercommunicating porosity is 2% or less.

Owner:DIAMET CORP

A titanium-based alloy material for 3D printing containing tungsten and its preparation method

ActiveCN106756240BHigh temperature hardnessExcellent high temperature wear resistanceAdditive manufacturing apparatusNiobiumAlloy

The invention discloses a titanium-based tungstenic alloy material used for 3D printing. The material contains tungsten carbide, nickel, niobium, vanadium, copper, molybdenum and titanium. A preparation method comprises the steps that metal powder is fully mixed after component design is completed; the mixed powder is subjected to sintering and alloy homogenizing; and then alloy powder is obtained through mechanical alloying. A 3D printing finished product of the obtained material has the advantages of being low in weight, high in high-temperature hardness, excellent in high-temperature abrasion resistance, and resistant to corrosion.

Owner:康硕电气集团有限公司

Preparation method of high-speed steel roll with compound modification treatment

The invention discloses a method for preparing a high-speed steel roll with compound modification treatment, and belongs to the technical field of steel rolling. Melt high-speed steel roll materials in an intermediate frequency induction furnace, and control the chemical composition and mass fraction of molten steel in the furnace at 2.32‑2.49%C, 4.17‑4.33%W, 4.80‑4.98%Mo, 9.63‑9.85%Cr, 0.48 ‑0.66% Mn, 0.57‑0.81% Si, <0.035% S, <0.040% P, the balance Fe; then heat the molten steel to 1615‑1626 ° C, add aluminum after 4‑5 minutes of heat preservation, and then use wire feeding method Metamorphic treatment, and pour molten steel into the high-speed rotating mold on the centrifuge. After the high-speed steel is solidified, fill the core with ductile iron under static conditions. After quenching and tempering, high-speed steel with excellent performance and good use effect can be obtained. roll.

Owner:安徽环渤湾高速钢轧辊有限公司

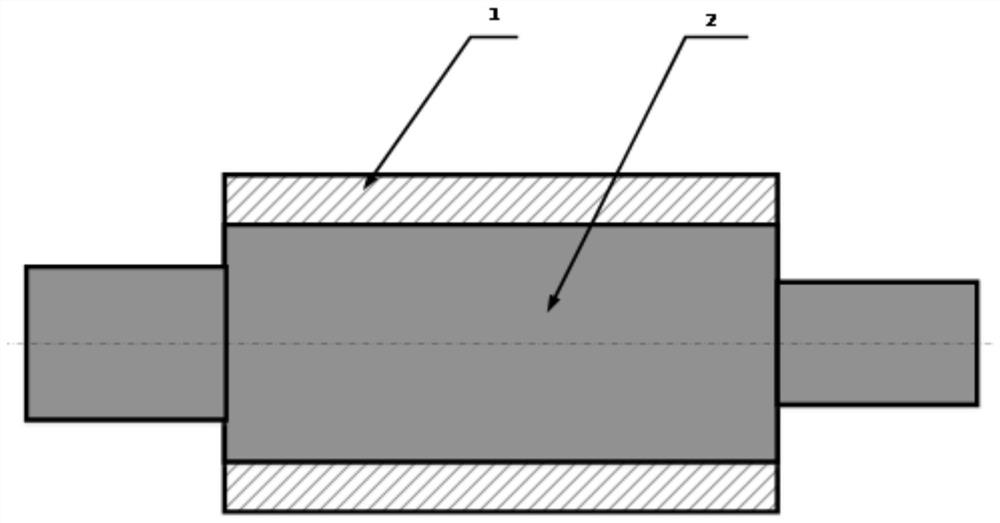

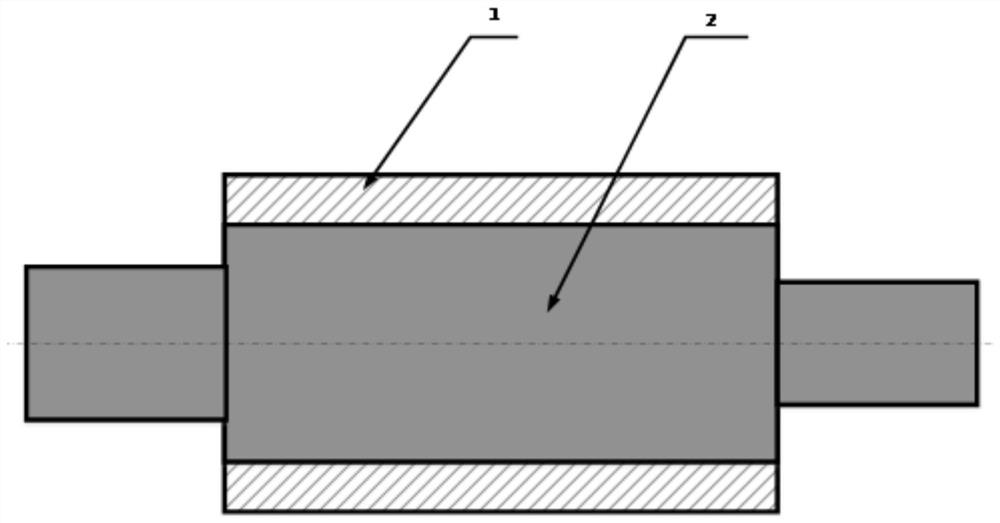

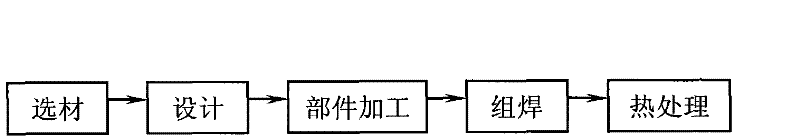

Manufacture method of installed and welded shearing tool of heavy forging

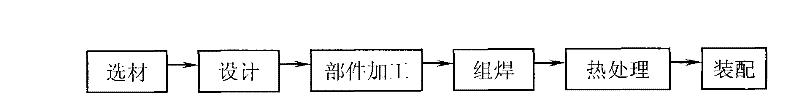

ActiveCN102114596BImprove the ability to resist high temperature plastic deformationExtended service lifeOther manufacturing equipments/toolsHigh energyEngineering

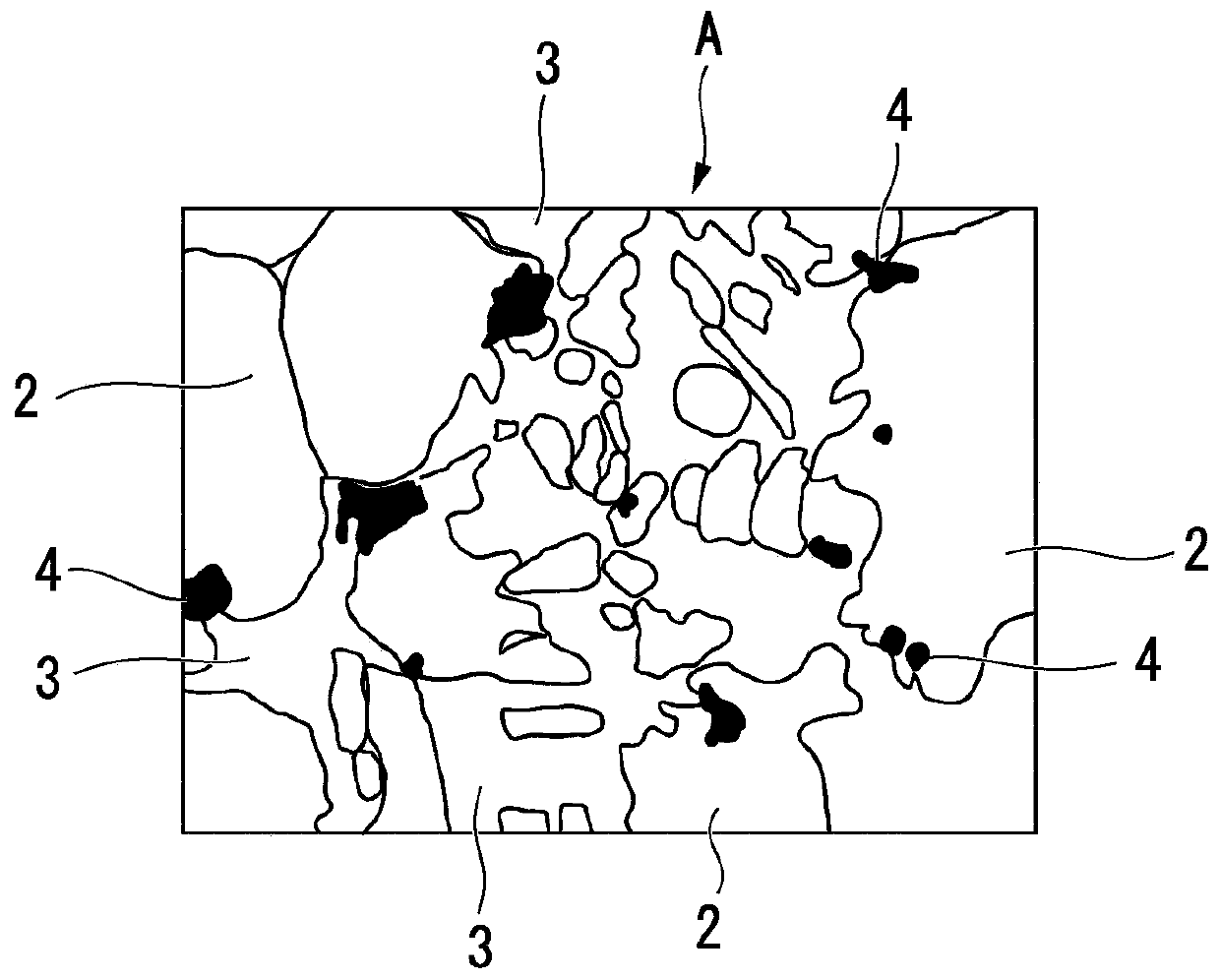

The invention relates to a manufacture method of an installed and welded shearing tool of a heavy forging, which is characterized by sequentially comprising the steps of: selecting materials, designing, processing parts, welding and thermally treating to obtain the installed and welded shearing tool of the heavy forging. A blade part (1) of the installed and welded shearing tool is made of a high-speed tool steel material with good high-temperature creep resistance, a support base body (2) is made of a common heat-resistant alloy steel material, the blade part and the support base body are subjected to shape and size design and milling machining, are welded by adopting a high-energy electronic beam and then subjected to high-temperature tempering thermal treatment to obtain the installed and welded shearing tool. The installed and welded shearing tool manufactured in the invention ensures that the blade has good high-temperature wear resistance, high-temperature plastic deformation resistance capability and high shearing quality for the heavy forging, has the advantages of manufacture material saving, low manufacture cost and long service life, can meet requirements for wear repairing and performance restoring after the blade is used for a long time, and replaces a traditional shearing tool for the heavy forging, made of the single material.

Owner:JIANGSU JINYUAN FORGE

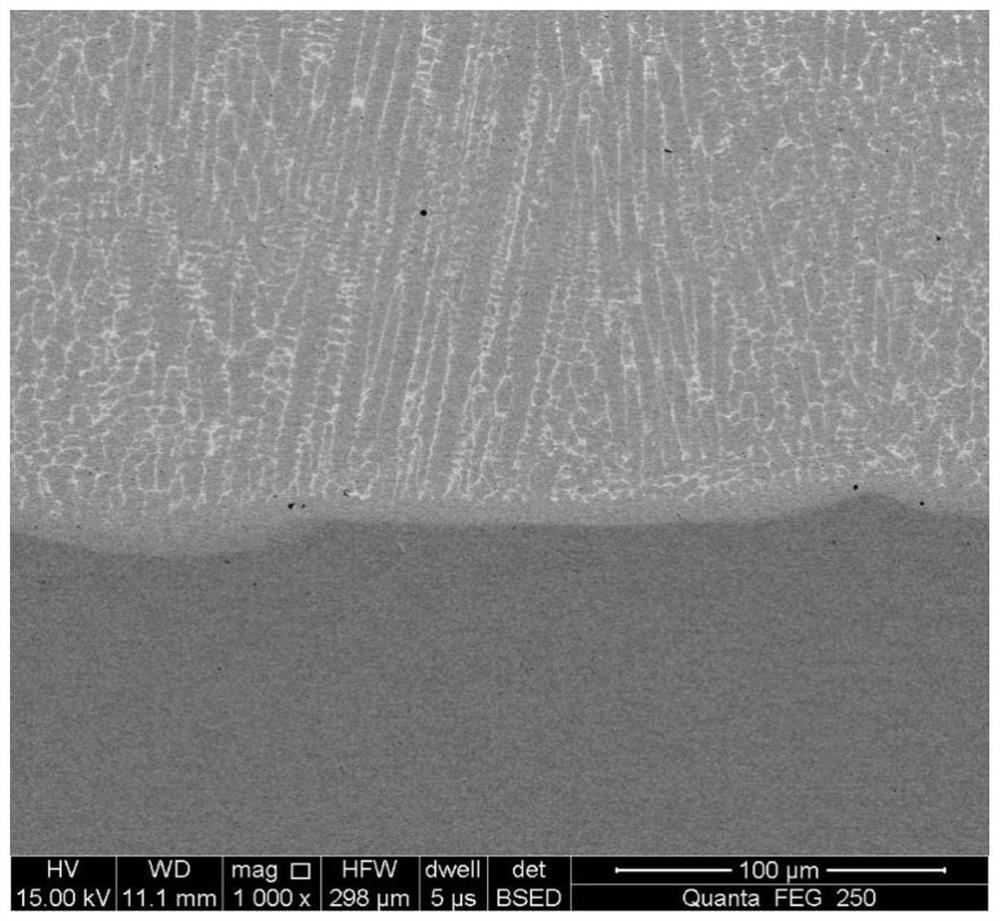

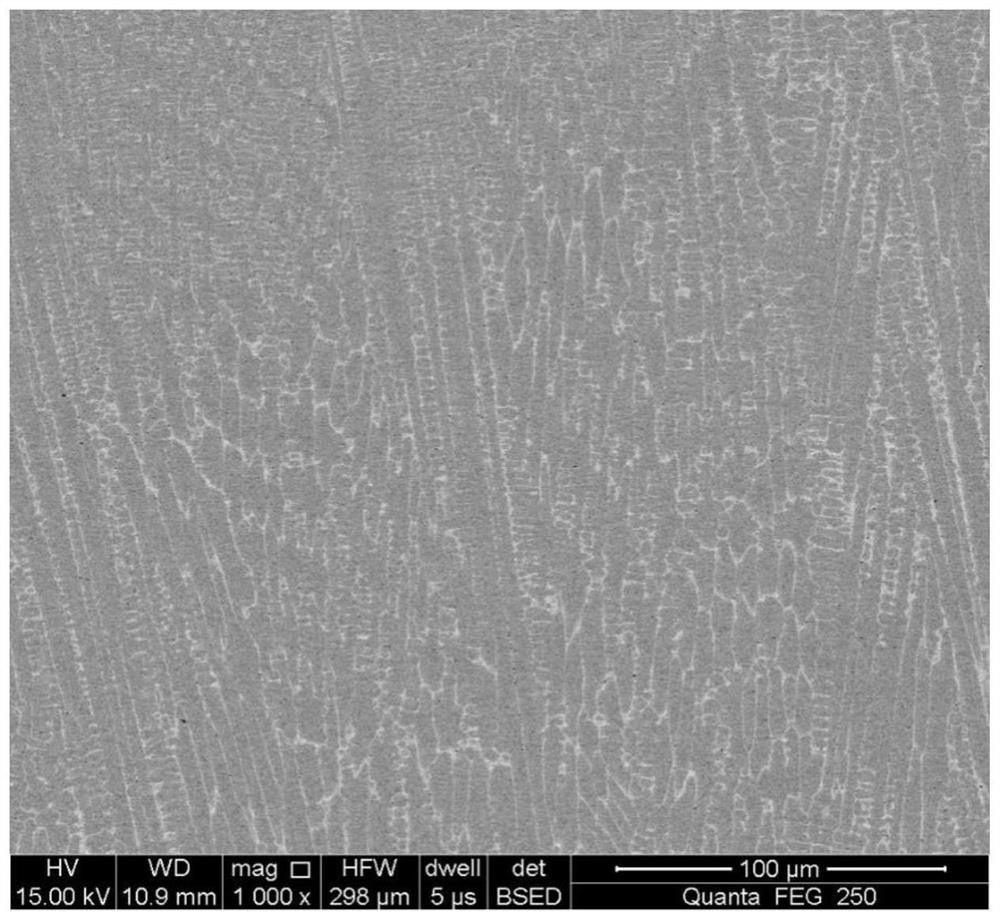

High-temperature gradient wear-resistant coating as well as preparation and application thereof

ActiveCN114574852AGood high temperature wear resistanceExcellent high temperature wear resistanceTransportation and packagingMetal-working apparatusVulcanizationCarbide

The invention belongs to the field of wear-resistant materials, and particularly discloses a high-temperature gradient wear-resistant coating which comprises a bottom layer, a transition layer, a wear-resistant layer and a vulcanization layer formed by vulcanization on the surface of the wear-resistant layer. The bottom layer comprises a martensite matrix and an intermetallic compound dispersed in the martensite matrix; each of the transition layer and the wear-resistant layer comprises a martensite matrix as well as an intermetallic compound and a carbide which are dispersed and distributed in the martensite matrix; wherein the content of intermetallic compounds in the transition layer and the wear-resistant layer is greater than the content of intermetallic compounds in the bottom layer; and the content of carbide in the wear-resistant layer is greater than that in the transition layer. The invention further comprises preparation and application of the coating, a wear-resistant material with the coating and preparation of the wear-resistant material. The research finds that the intermetallic compound and carbide double-gradient controlled hierarchical coating has excellent synergism, and the high-temperature (such as 700 DEG C) wear resistance of the coating can be remarkably improved.

Owner:长沙市萨普新材料有限公司

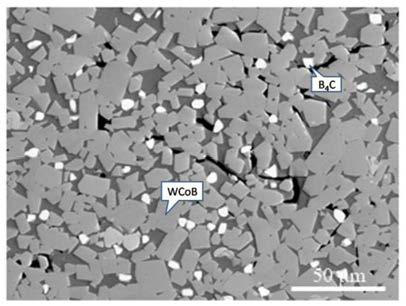

a wcob-b 4 C preparation method of ceramic matrix composite material

The invention discloses a preparation method of a WCoB-B<4>C ceramic matrix composite material. The preparation method of the WCoB-B<4>C ceramic matrix composite material comprises the steps that powder blending is carried out on 65.6%-69.1% of W powder, 26.5%-28.8% of Co powder, 0.5% of C powder and 4.0%-5.2% of B powder by mass fraction, wet method ball milling treatment is carried out on the mixed powder, the treated powder is pressed into shapes after dried and sifted, and finally, the WCoB-B<4>C ceramic matrix composite material is manufactured by vacuum sintering. The preparation methodof the WCoB-B<4>C ceramic matrix composite material is simple in process, and the obtained WCoB-B<4>C ceramic matrix composite material has the characteristics of high hardness, high using temperatureand good high temperature resistance abrasion performance.

Owner:XI AN JIAOTONG UNIV

Heat-resistant sintered material excellent in oxidation resistance, high-temperature wear resistance, and salt corrosion resistance, and production method thereof

ActiveCN107429350BExcellent resistance to salt corrosionImprove antioxidant capacityTurbinesAlloyWear resistance

Owner:DIAMET CORP

Treatment method for improving wear resistance of mold

InactiveCN107893150AImprove surface qualityExcellent high temperature wear resistanceFireproof paintsFurnace typesWear resistantPre treatment

The invention discloses a treatment method for improving wear resistance of a mold. The treatment method comprises the following steps of (1), surface pretreatment; (2), coating treatment; (3), quenching treatment. By means of the treatment method for improving the wear resistance of the mold, the treated mold has quite good high-temperature wear-resistant stability, the mold repairing rate of thetreated mold is obviously reduced, the service life of the treated mold is obviously prolonged, the surface performance of prepared products is better, and the treatment method for improving the wearresistance of the mold has high use and popularization values.

Owner:蚌埠市宏大制药机械有限公司

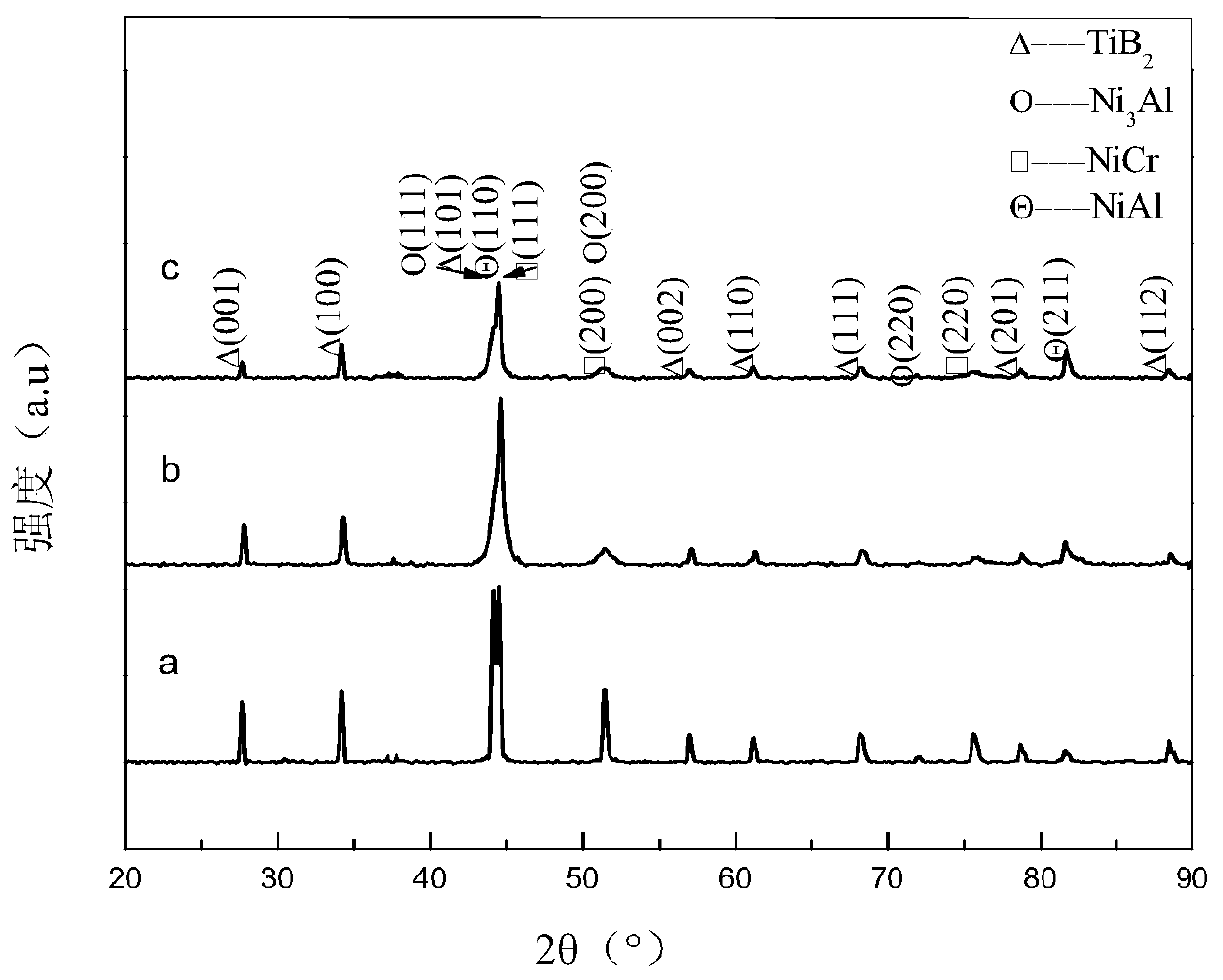

A kind of high-performance metal-ceramic composite powder used as thermal spraying structure feeding material and its preparation method

InactiveCN107243640BImprove high temperature wear resistanceHigh bonding strengthMolten spray coatingTransportation and packagingCeramic compositeBall mill

The invention belongs to the technical field of nanocomposite materials, and discloses a high-performance cermet composite powder used as a feed material for thermal spraying structures and a preparation method thereof. Described method is: (1) with 20~40wt.%TiB 2 Mix the powder with 60-80wt.% NiCrCoAlY powder evenly to get NiCrCoAlY‑TiB 2 Mixed powder; (2) NiCrCoAlY‑TiB 2 The mixed powder and process control agent are placed in a ball mill, wet-milled in an inert gas atmosphere, dried, and cooled to obtain a composite powder; (3) in an inert gas atmosphere, the composite powder is ball-milled and plasma spheroidized to obtain High-performance cermet nanocomposite powder. The composite powder has the properties of high temperature wear resistance, thermal fatigue resistance, corrosion resistance and high temperature oxidation resistance, good fluidity and density, and the particle size is still mainly concentrated in 5-50 μm; the preparation method is simple and easy to operate, and is environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com