High-temperature-resistant and wear-resistant hard alloy and preparation method thereof

A cemented carbide and high temperature resistant technology, applied in the field of cemented carbide materials and their preparation, can solve the problems of high brittleness and insufficient oxidation resistance of NiAl alloys, and achieve the effects of high brittleness, avoiding heat accumulation and preventing self-propagating reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 27-31)

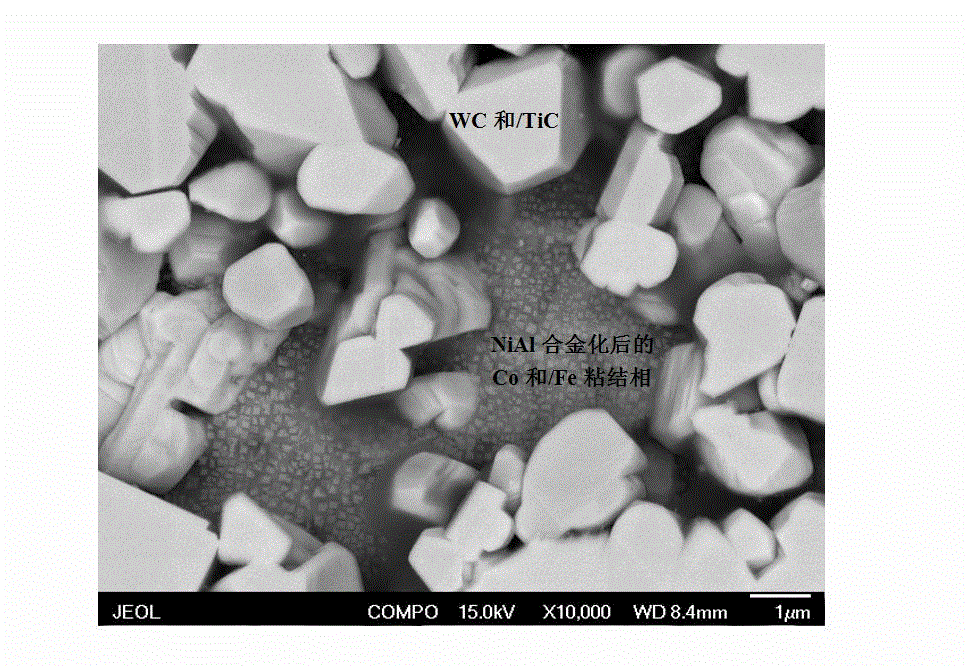

[0014] As a further improvement, the hard phase is WC and TiC, and the mass percentage of WC and TiC is 3.18-1.59:1; the binder phase is NiAl alloyed Co and Fe, and the volume percentage is 25%-40%.

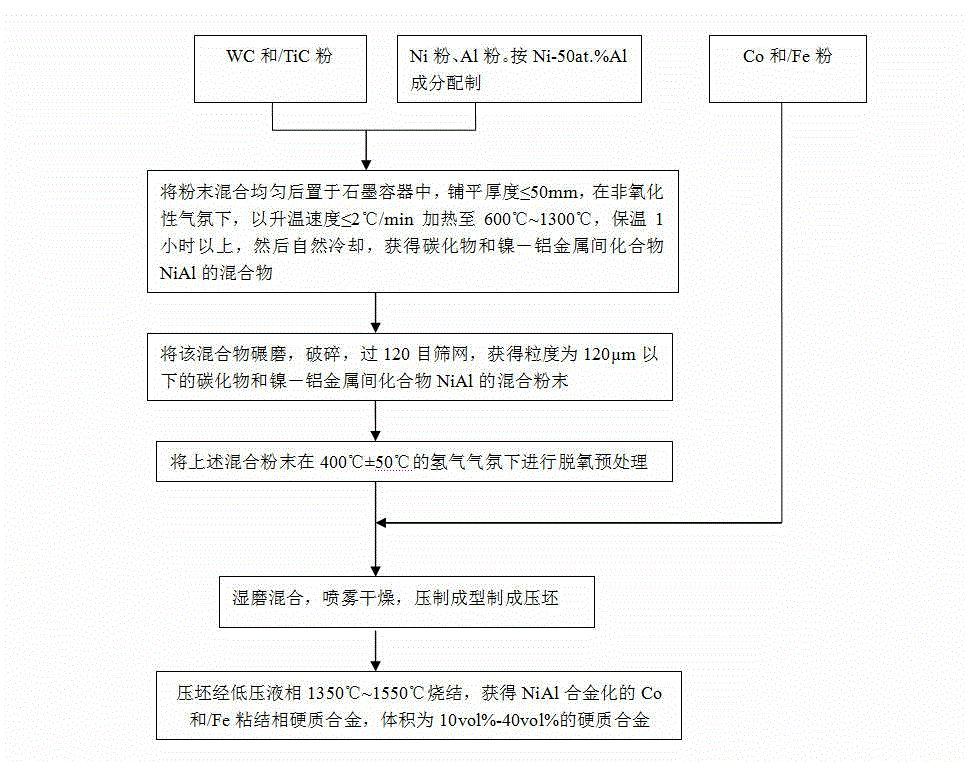

[0015] Simultaneously, the present invention also provides the preparation method of this cemented carbide, comprises the following steps successively:

[0016] (1) According to the composition ratio of nickel-aluminum intermetallic compound Ni-50at.%Al, mix nickel powder, aluminum powder and carbide powder evenly; the mass percentage of nickel powder and aluminum powder in the mixed powder is 0.03%~ 21.04%, the balance is carbide powder;

[0017] (2) Place the above mixed powder in a graphite container and pave it with a thickness of ≤50mm. In a non-oxidizing atmosphere, heat it to 660°C~1300°C at a heating rate of ≤2°C / min, keep it warm for more than 1 hour, and then cool it naturally to obtain a mixture of carbide and nickel-aluminum intermetallic compound NiAl; grind the mix...

Embodiment 1

[0028] Embodiment 1: According to figure 1In the process shown, according to the composition ratio of Ni-50at.%Al, the nickel powder and aluminum powder with a mass percentage of 0.03% are mixed evenly with the remaining WC powder (99.97%); the above mixed powder is placed in a graphite container Pave the thickness of 50 mm, in a non-oxidizing atmosphere, heat up to 660 °C at a heating rate of 2 °C / min, keep it for 4 hours, and then cool naturally to obtain a mixture of WC and nickel-aluminum intermetallic compound NiAl; Grind, crush, and pass through a 120-mesh sieve to obtain a mixed powder of WC+NiAl with a particle size of less than 120 μm; perform deoxidation pretreatment on the mixed powder of WC+NiAl above in a hydrogen atmosphere at 400°C±50°C; then, the mass The above-mentioned deoxidized pretreated WC+NiAl mixed powder with a percentage of 94.12% was wet-milled with the remaining Co powder (5.88%) for 18 hours to obtain a wet-milled mixture; the wet-milled mixture wa...

Embodiment 2-13

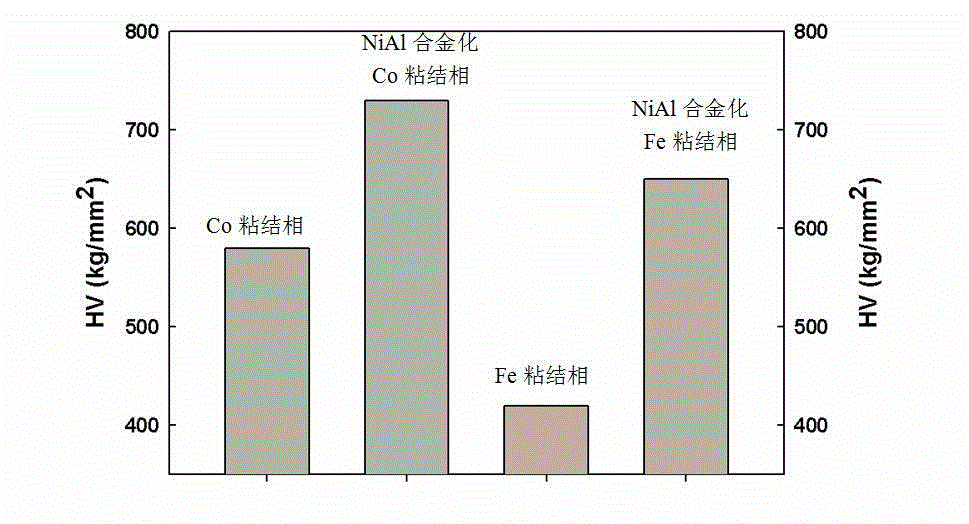

[0029] In Examples 2-13, NiAl-alloyed Co binder phase was used to prepare high-temperature wear-resistant cemented carbide. The process was the same as in Example 1, and the process parameters were shown in Table 1. Wherein the hard phase of embodiment 1-5 is WC; the hard phase of embodiment 6-10 is TiC; the hard phase of embodiment 11-13 is WC and TiC.

[0030] Table 1 Preparation parameters of NiAl alloyed Co binder phase high temperature wear resistant cemented carbide

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com