Preparation method of high-temperature wear-resistant coating on surface of steel piece

A high-temperature wear-resistant and wear-resistant coating technology, which is applied in coating, metal material coating process, hot-dip plating process, etc., can solve the problems of corrosion resistance and high-temperature oxidation resistance without high-temperature wear resistance, and achieve good Corrosion resistance and high temperature oxidation resistance, unlimited size, easy industrial production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

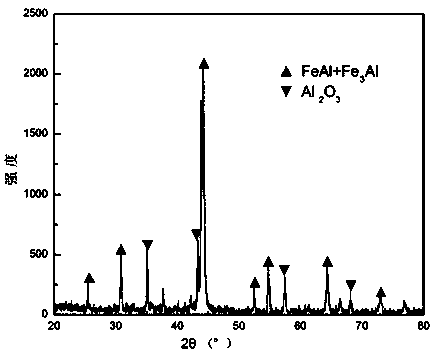

Embodiment 1

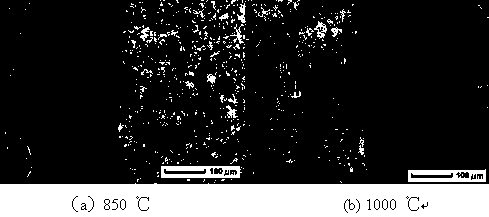

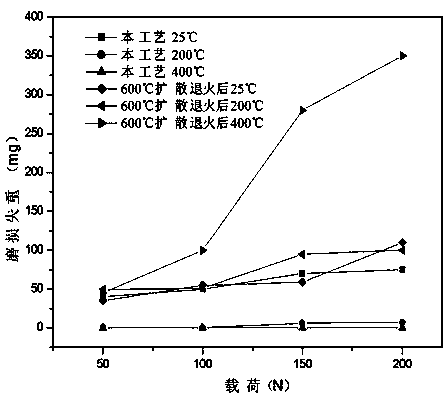

[0019] The surface of 45 steel parts is pre-treated: after the surface is polished, it is degreased by 10wt% NaOH aqueous solution at 60°C for 10 minutes, and then washed with water; then it is derusted by 5wt% HCl aqueous solution at 40°C for 10 minutes, and then washed and air-dried; the steel piece is immersed in a temperature of 80°C 6wt%NaCl+4wt%KF (mass percent concentration) aqueous solution for 10min, then dry; place the pretreated steel piece in 720°C aluminum liquid for 10min, take it out and air cool to room temperature; First, it was kept at 850°C in vacuum for 5 hours; then at 400°C in air for 30 minutes; 3 Al intermetallic compound and 6wt% Al 2 o 3 Composite wear-resistant coating.

Embodiment 2

[0021] The surface of 20CrMnTi steel parts is pre-treated: after the surface is polished, it is degreased by 20wt% NaOH aqueous solution at 50°C for 10 minutes, and then washed with water; then it is derusted by 8wt% HCl aqueous solution at 50°C for 10 minutes, and then washed and air-dried; the steel piece is immersed in a temperature of 80 5wt%KCl+4wt%NaCl+1wt%Na at ℃ 3 AlF 6 Help plating in aqueous solution for 10 minutes, then dry; immerse in molten aluminum at 750°C for 5 minutes, take it out and cool to room temperature in air; under argon protection, diffuse at 1100°C for 2 hours; then heat in air at 500°C 25min to obtain a thickness of 360μm, containing 92wt% FeAl and Fe 3 Al intermetallic compound and 8wt% Al 2 o 3 Composite coating.

Embodiment 3

[0023] Pretreatment on the surface of H13 steel parts: after the surface is polished bright, degrease with 15wt% NaOH aqueous solution at 70°C for 8 minutes, wash with water; %KCl+3wt%NaCl+1wt%NaF aqueous solution for 10min, then dry; immerse in molten aluminum at 800°C for 1min, take it out and air cool to room temperature; under argon protection, 1000°C diffusion treatment for 1h; Then heated in air at 600°C for 20min to obtain a 210μm-thick, 90wt%FeAl and Fe 3 Al intermetallic compound and 10wt% Al 2 o 3 Composite coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com