Laser near net forming method of functional graded friction stir welding stirring head

A laser near-net-shaping and friction stir welding technology is applied in the field of friction stir welding, laser processing technology, and functionally graded materials, and can solve the problems of easy wear, high manufacturing cost of tungsten-based materials, and fracture of polycrystalline cubic boron nitride materials. problems such as low toughness, to achieve the effect of improving the service life, improving the overall fracture toughness, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

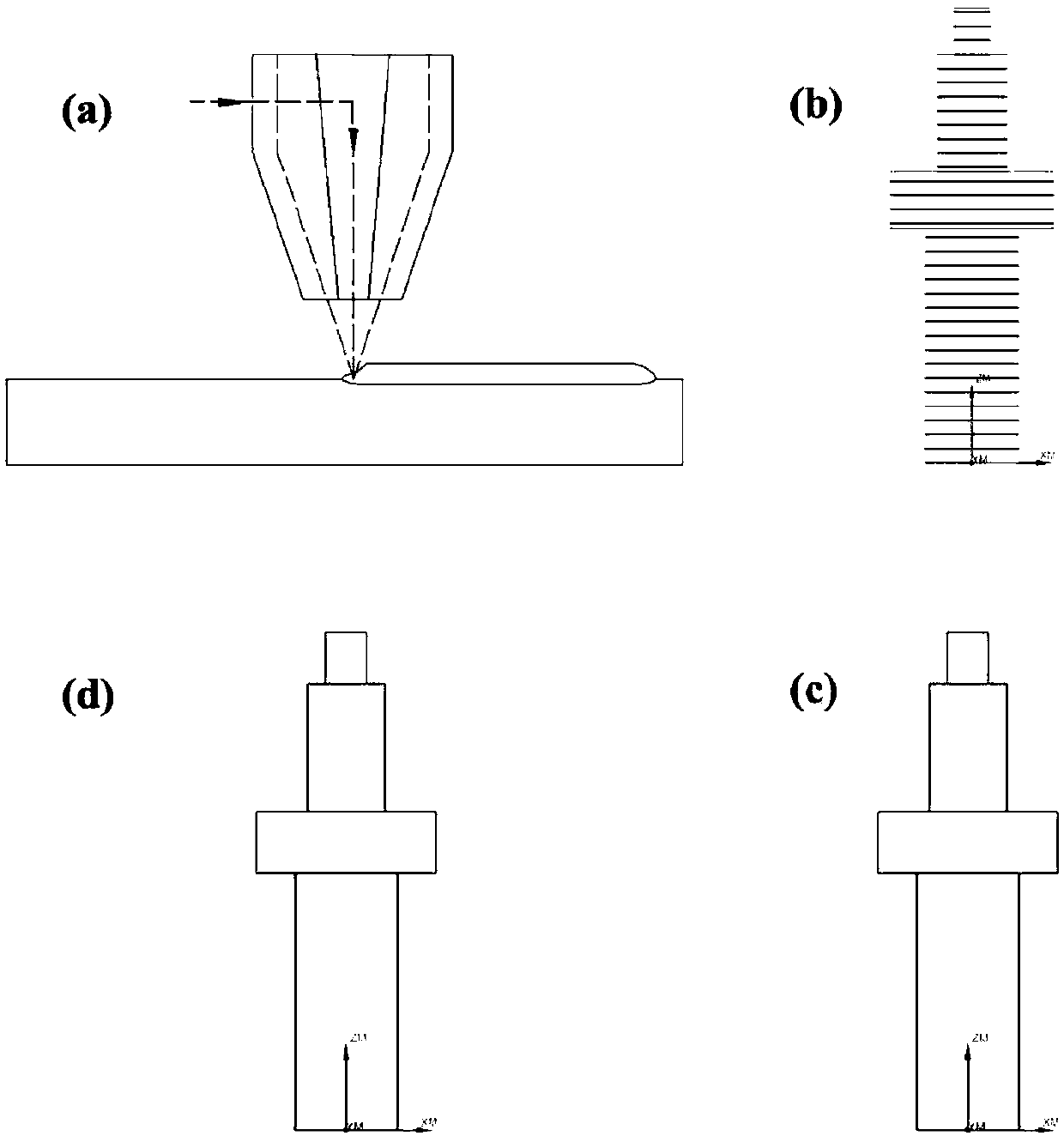

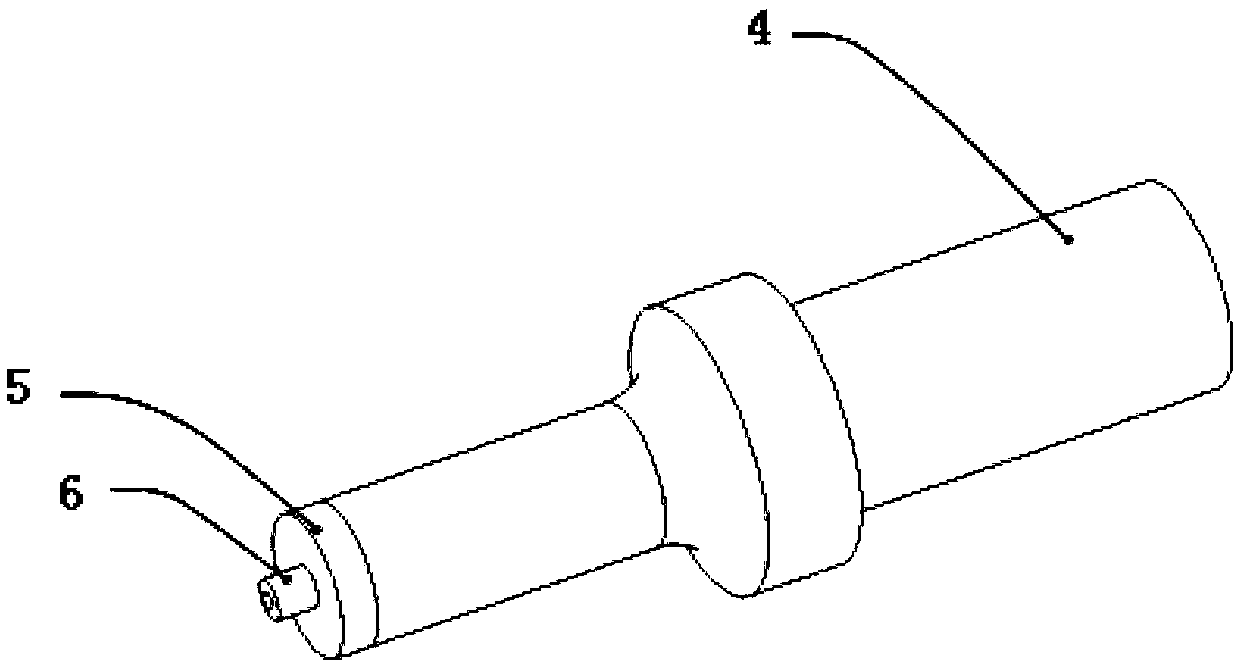

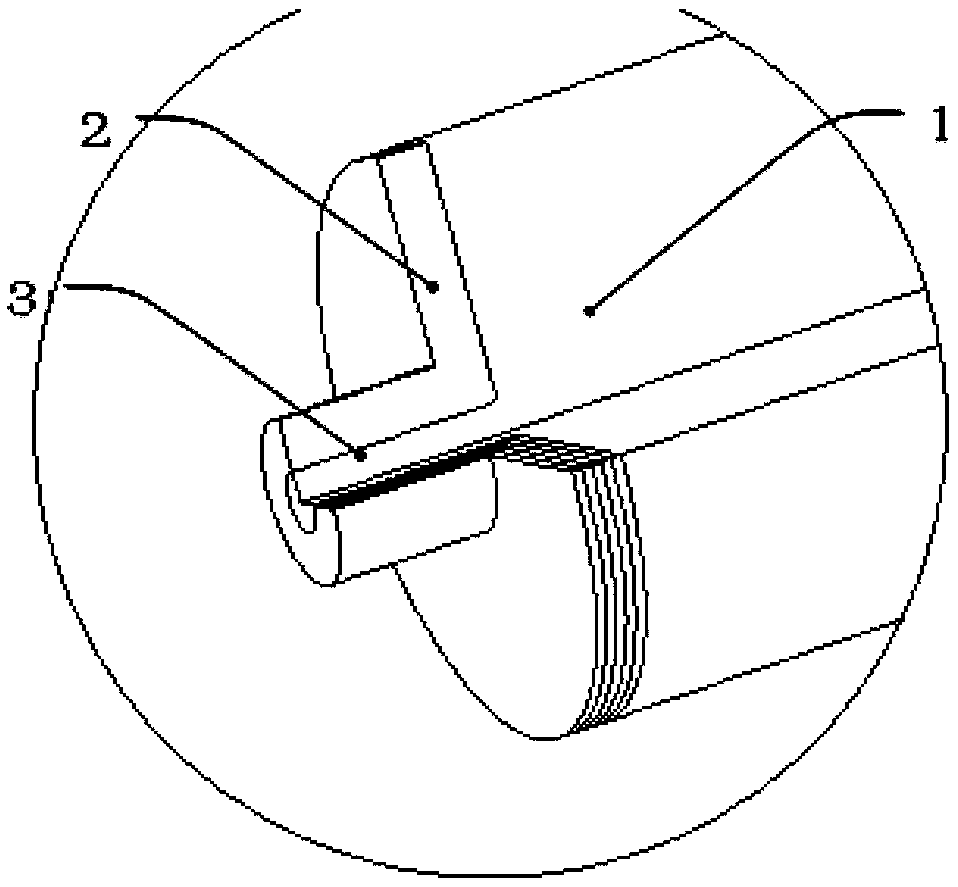

[0019] The preparation method of the functionally gradient friction stir welding stirring head proposed by the present invention will be further clearly described below in conjunction with the accompanying drawings and specific examples. Advantages and features of the present invention will be apparent from the following description and claims.

[0020] The core idea of the present invention is that the functional gradient friction stir welding stirring head laser near-net forming method provided by the present invention can realize the material of the stirring head from the material with good toughness, high strength and good economy in the main part of the stirring head to the material of the stirring head The material with good high temperature and wear resistance on the end face of the shaft shoulder and the surface of the stirring needle can realize the composition gradient transition, and then realize the performance gradient transition.

[0021] The present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com