Organic silicon gel anti-ice-covering coating as well as preparation method and application thereof

An anti-icing and silicone gel technology, applied in chemical instruments and methods, coatings, other chemical processes, etc., can solve problems such as the stability limitation of the liquid interface layer, and achieve long-term effective anti-icing function and excellent mechanical properties. , Durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

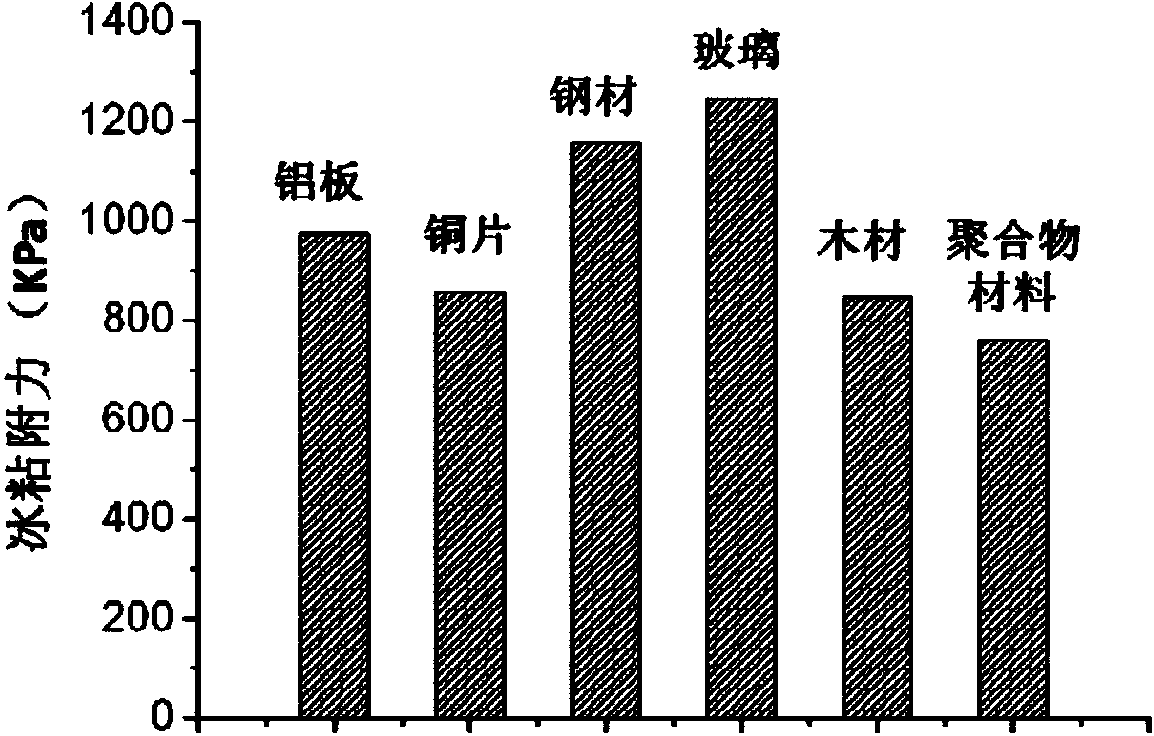

Problems solved by technology

Method used

Image

Examples

Embodiment 1

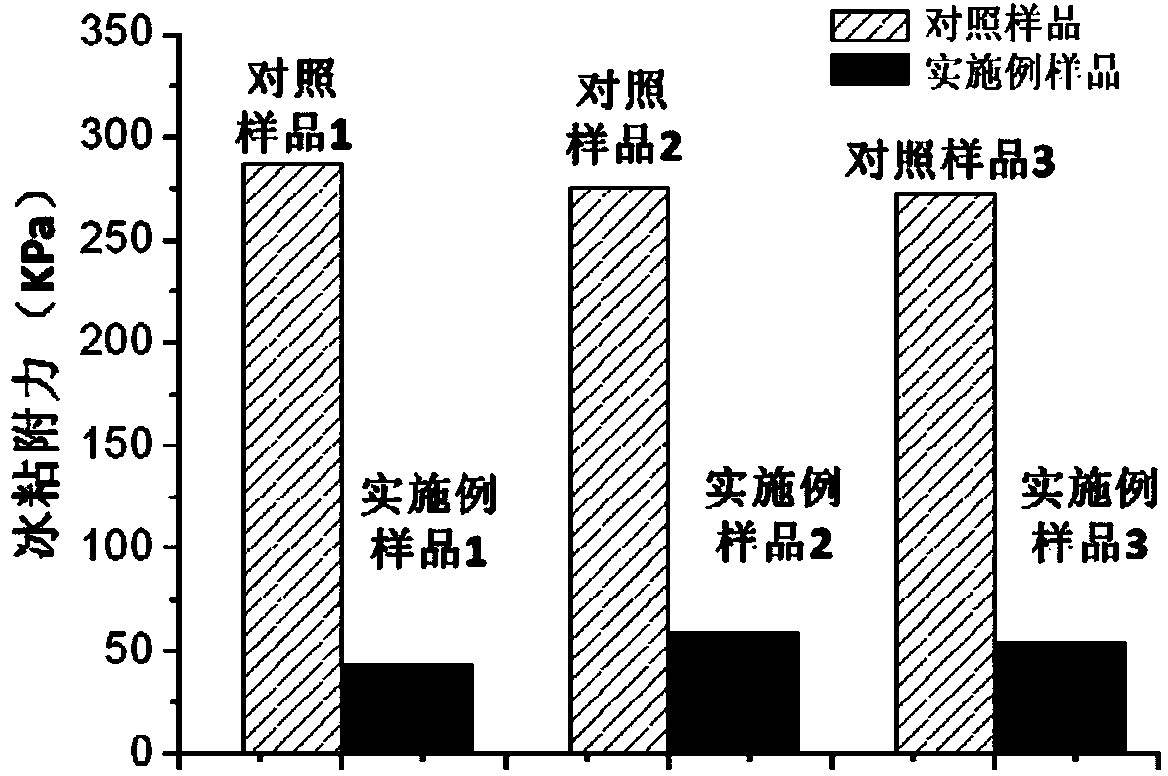

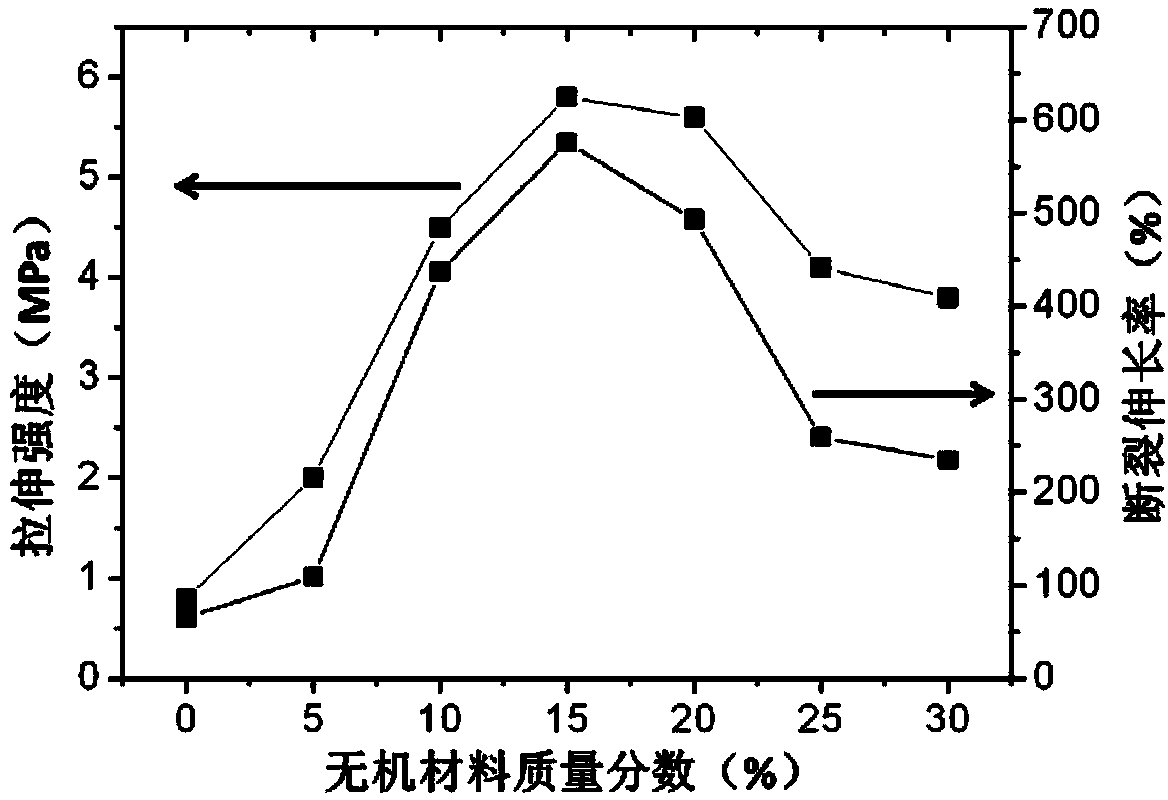

[0047] 20% by mass fraction of dihydroxy polydimethylsiloxane (n=200), 1% by mass fraction of methyltriacetoxysilane, 0.1% by mass fraction of octyltin and 0.9% by mass fraction of amine Propyltrimethoxysilane, silicone oil with a mass fraction of 68% (viscosity is 0.1cm 2 / s) and diatomaceous earth with a mass fraction of 10% were mixed and ball milled for 12 hours to make it uniform, so as to obtain the anti-icing coating. The anti-icing coating is directly coated on the surface of the copper sheet, and cured at room temperature for 48 hours to obtain a silicone gel anti-icing coating with low ice adhesion.

[0048] When the ambient temperature is 0~-40°C and the ambient humidity is 40%~90%, which can cause the surface of the copper sheet to freeze, the above-mentioned low ice adhesion silicone gel anti-icing coating can prevent supercooled water from contacting copper. The sheet reduces the icing on the surface of the copper sheet and greatly reduces the adhesion of the ic...

Embodiment 2

[0050] The mass fraction is 28% dihydroxypolymethylphenylsiloxane (n=40), the mass fraction is 1.5% propyltriethoxysilane, the mass fraction is 0.1% dibutyl tin laurate and mass fraction Fraction is 0.4% aminopropyltriethoxysilane, mass fraction is 60% silicone oil (viscosity is 10cm 2 / s) mixed with 10% active alumina by mass fraction and ball milled for 6 hours to make it uniform to obtain the anti-icing coating. The anti-icing coating is directly coated on the surface of an aluminum sheet, and cured at 40° C. for 30 hours to obtain a silicone gel anti-icing coating with low ice adhesion.

[0051] When the ambient temperature is 0-40°C and the ambient humidity is 40%-90%, which can cause the surface of the aluminum sheet to freeze, the above-mentioned low ice adhesion silicone gel anti-icing coating can prevent supercooled water from contacting the aluminum sheet. The sheet reduces the icing on the surface of the aluminum sheet and greatly reduces the adhesion of the ice la...

Embodiment 3

[0053] The mass fraction is 45% dihydroxypolyethylethoxysiloxane (n=300), the mass fraction is 2% tetraethoxysilane, the mass fraction is 0.5% dibutyl tin laurate and the mass fraction 0.5% propanesulfonate trimethoxysilane, mass fraction is 40% silicone oil (viscosity is 30cm 2 / s) and mass fraction of 12% activated carbon mixed and ball milled for 40 hours to make it uniform, to obtain the anti-icing coating. The anti-icing coating is directly coated on the surface of the iron sheet, and cured at 60°C for 24 hours to obtain a silicone gel anti-icing coating with low ice adhesion.

[0054] When the ambient temperature is 0-40°C and the ambient humidity is 40%-90%, which can cause the surface of the iron sheet to freeze, the low ice adhesion silicone gel anti-icing coating prepared above can prevent supercooled water from contacting the iron sheet. The sheet reduces the icing on the surface of the iron sheet and greatly reduces the adhesion of the ice layer, and the ice layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ice adhesion strength | aaaaa | aaaaa |

| ice adhesion strength | aaaaa | aaaaa |

| ice adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com