A "two-step method" preparation method of lubricious and durable silicone anti-icing coating

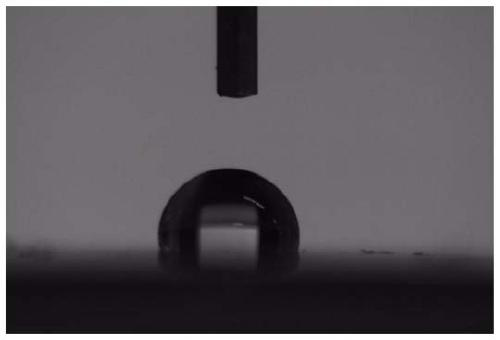

A lubricity and anti-icing technology, applied in the direction of coating, etc., to achieve low ice shear strength, excellent wear resistance, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

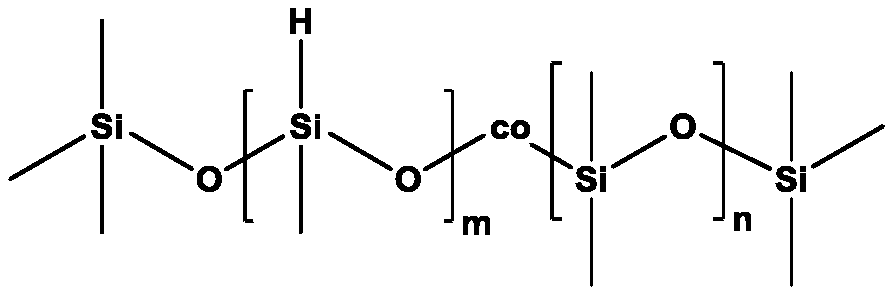

[0052] 1) Synthesis of PDMS brush-type graft polymer

[0053] 2.0g main chain PDMS-PMHS (molecular weight is 62000) and 3.0g branched chain PDMS-V (molecular weight is 500) and 45.0g tetrahydrofuran are mixed and prepared into the homogeneous reaction solution that solute mass percentage content is 10wt%; Under nitrogen protection Add 120 μL of Karstedt's catalyst (0.001% of reactant mass) in tetrahydrofuran (solution mass fraction: 2.75wt%) to the above system; heat up to 60°C, condense and reflux for 18.8h under stirring; The product was taken out, rotated at 30°C to remove as much solvent as possible, and dried in a vacuum oven for 24 hours to remove residual solvent.

[0054] A PDMS brush-type graft polymer (molecular weight: 70,000) with a grafting degree of 20% was prepared.

[0055] 2) Preparation of lubricious and durable silicone anti-icing coating

[0056] 2.0g of the above-mentioned PDMS brush-type graft polymer (molecular weight is 70000), 3.0g crosslinking agent...

Embodiment 2

[0059] 1) Synthesis of PDMS brush-type graft polymer

[0060] 8.5g main chain PDMS-PMHS (molecular weight is 8000) and 6.5g branched chain PDMS-V (molecular weight is 3750) is mixed with 35.0g toluene and is formulated into the homogeneous reaction solution that solute mass percentage content is 30wt%; Under nitrogen protection Add 80 μL of Karstedt's catalyst (0.001% of reactant mass) in toluene solution (solution mass fraction is 5.0wt%) to the above system; heat up to 75°C, condense and reflux for 34h under stirring; after the reaction, the crude product Take it out, rotate it at 55°C to remove as much solvent as possible, and dry it in a vacuum oven for 48 hours to remove the residual solvent.

[0061] A PDMS brush-type graft polymer (molecular weight: 104,000) with a grafting degree of 50% was prepared.

[0062] 2) Preparation of lubricious and durable silicone anti-icing coating

[0063] 6.0g of the above-mentioned PDMS brush-type graft polymer (molecular weight is 104...

Embodiment 3

[0066] 1) Synthesis of PDMS brush-type graft polymer

[0067] 3.0g main chain PDMS-PMHS (molecular weight is 120000) and 2.0g branched chain PDMS-V (molecular weight is 7000) are mixed with 5.0g dichloromethane and are formulated into the homogeneous reaction solution that solute mass percentage content is 50wt%; Add 65 μL of Karstedt's catalyst (0.001% of reactant mass) in dichloromethane solution (solution mass fraction: 5.0 wt%) to the above system under protection; heat up to 90°C, condense and reflux for 10 h under stirring; the reaction ends Finally, the crude product was taken out, rotary evaporated at 30° C. to remove as much solvent as possible, and dried in a vacuum oven for 24 hours to remove residual solvent.

[0068] A PDMS brush-type graft polymer (molecular weight: 200,000) with a grafting degree of 33.3% was obtained.

[0069] 2) Preparation of lubricious and durable silicone anti-icing coating

[0070] 9.5g of the above-mentioned PDMS brush-type graft polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com