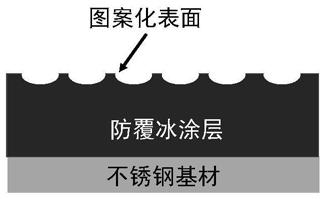

Patterning polysiloxane anti-icing coating and preparation method thereof

A technology of polysiloxane and polysilsesquioxane, applied in the direction of coating, etc., to achieve good mechanical stability, easy operation, and excellent anti-icing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

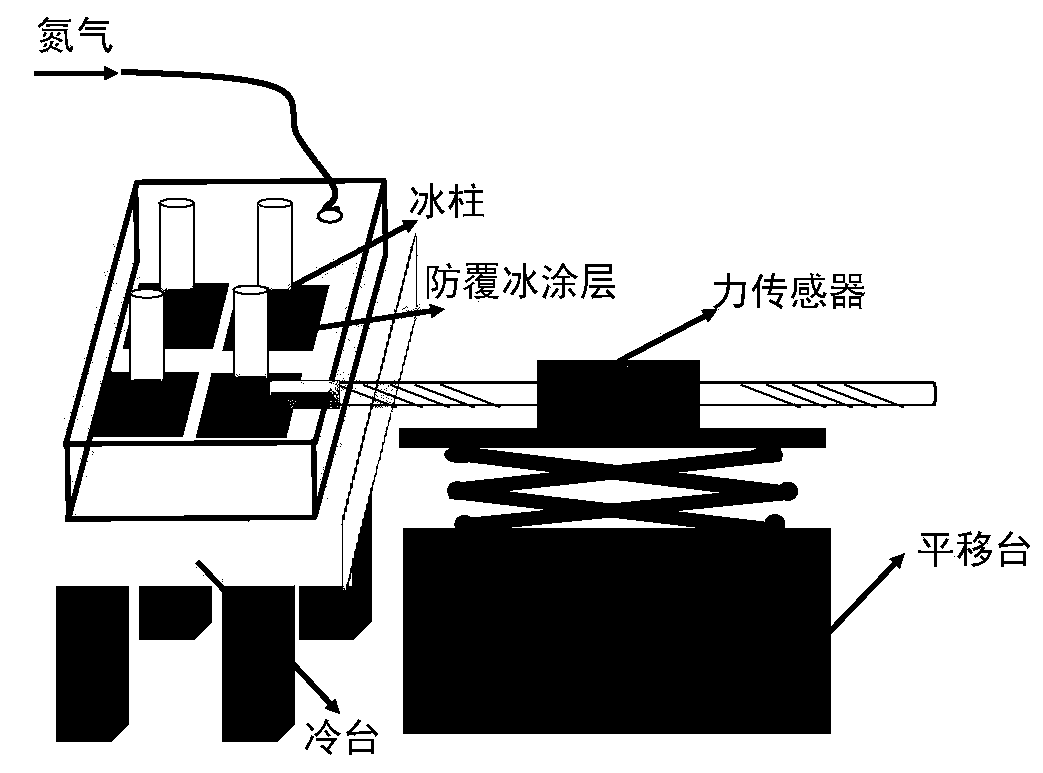

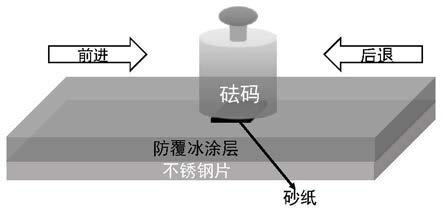

[0041]Preparation of patterned polysiloxane anti-icing coatings. Get 2g of branched polydimethylsiloxane, 0g of fluorinated polyhedral oligomeric silsesquioxane (the number of silicon-hydrogen bond is 1), 4g of double-terminal hydrogen polydimethylsiloxane (molecular weight 20000) and 7 μL of Karstedt's catalyst were uniformly mixed, 14 g of dichloromethane was used as a solvent, and the concentration of the reactant solution was 30 wt%. ×2cm aluminum sheet, after drop coating, place the coating in an environment with a temperature of 15°C and a relative humidity of 45% for 4 hours, and then put it in an oven at 80°C to fully cross-link and cure for 5 hours.

[0042] The ice shear strength of the coating was measured to be 29kPa, and the abrasion resistance was 1000 times.

Embodiment 2

[0044] Preparation of patterned polysiloxane anti-icing coatings. Get 2.5g of branched polydimethylsiloxane, 1g of fluorinated polyhedral oligomeric silsesquioxane (the number of silicon-hydrogen bonds is 3), 7g of double-terminal hydrogen polydimethylsiloxane (molecular weight 500) and 17 μL of chloroplatinic acid catalyst were uniformly mixed, 29.5 g of carbon disulfide was used as a solvent, and the concentration of the reactant solution was 21 wt%. ×2cm aluminum sheet, after drop coating, place the coating in an environment with a temperature of 25°C and a relative humidity of 60% for 2 hours, and then put it in an oven at 120°C to fully cross-link and cure for 2 hours.

[0045] The ice shear strength of the coating was measured to be 30kPa, and the abrasion resistance was 1800 times.

Embodiment 3

[0047] Preparation of patterned polysiloxane anti-icing coatings. Get 4g of branched polydimethylsiloxane, 1.5g of fluorinated polyhedral oligomeric silsesquioxane (the number of silicon-hydrogen bonds is 7), 10g of double-terminal hydrogen polydimethylsiloxane ( Molecular weight is 10000) and Karstedt's catalyst of 13 μ L carry out homogeneous mixing, 34.5g dichloromethane is used as solvent, the concentration of being made into reactant solution is 31wt%, after shaking for 2h, get mixed reaction solution 330 μ L, evenly drip-coat on the processed On a 2cm×2cm aluminum sheet, after drop coating, place the coating in an environment with a temperature of 45°C and a relative humidity of 85% for 3 hours, and then put it in an oven at 100°C to fully cross-link and cure for 3.5 hours.

[0048] The measured ice shear strength of the coating is 26kPa, and the abrasion resistance is 2200 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com