PVP-based amphiphilic anti-icing coating and preparation method thereof

A technology of amphiphilic and amphiphilic polymers, which is applied in the field of organic materials, can solve the problems of poor durability, passive anti-icing methods cannot achieve anti-icing performance, and anti-icing materials do not have sufficient durability. Easy to operate, enhance the effect of anti-icing and reduce the effect of ice shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

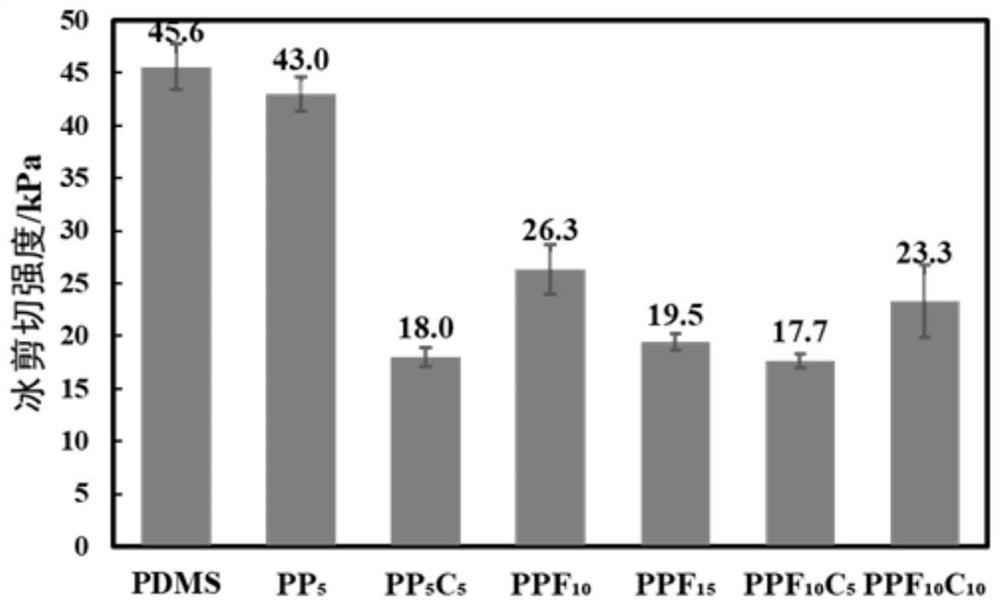

[0037] Embodiment 1: Take 3.7g CTA-PDMS-CTA (0.625mmol), 11.11g NVP (100mmol), 16.4mg 2,2-azobisisobutyronitrile AIBN (1.0mmol) is dissolved in 8mL 1,4-diox Add it to a dry round-bottomed flask, and deoxygenate the solution by bubbling nitrogen gas at room temperature for 30 minutes, then immerse the flask in an oil bath preheated to 75°C, react under stirring for 24 hours, and then use ice-water mixture Quenched. The reacted solution was concentrated and precipitated at least three times in ten volumes of cold ether, the solid was collected after filtration, and then vacuum-dried at 40°C overnight to obtain the amphiphilic polymer PVP-PDMS-PVP.

[0038] Dissolve 5.0g PDMS (molecular weight: 26000), 0.25g PVP-PDMS-PVP in a mixed solution of 3mL dichloromethane and 5mL tetrahydrofuran, mix well, add 0.1g cross-linking agent METES and 50mg catalyst DBTDL, and spread the solution evenly Overlay clean 20×20mm 2 On the surface of the steel sheet, the amphiphilic polymer anti-icin...

Embodiment 2

[0040] Embodiment 2: get 7.4g CTA-PDMS-CTA (1.25mmol), 22.22g NVP (200mmol), 32.8mg AIBN (2.0mmol) are dissolved in 16mL 1,4-dioxane, add it to dry circular In the bottom flask, the solution was deoxygenated by bubbling argon gas at room temperature for 30 min, then the flask was immersed in an oil bath preheated to 75 °C, and reacted for 24 h under stirring, and then quenched with ice-water mixture. The reacted solution was concentrated and precipitated at least three times in ten volumes of cold ether, the solid was collected after filtration, and then vacuum-dried at 40°C overnight to obtain the amphiphilic polymer PVP-PDMS-PVP.

[0041] 8.0g PDMS (molecular weight is 26000), 0.4g PVP-PDMS-PVP and 0.4g carbon fiber are dissolved in the mixed solution of 6mL dichloromethane and 8mL tetrahydrofuran, after mixing, add 0.24g cross-linking agent METES and 120mg catalyst DBTDL, Spread the solution evenly on a clean 40×40mm 2 On the surface of the steel sheet, the amphiphilic pol...

Embodiment 3

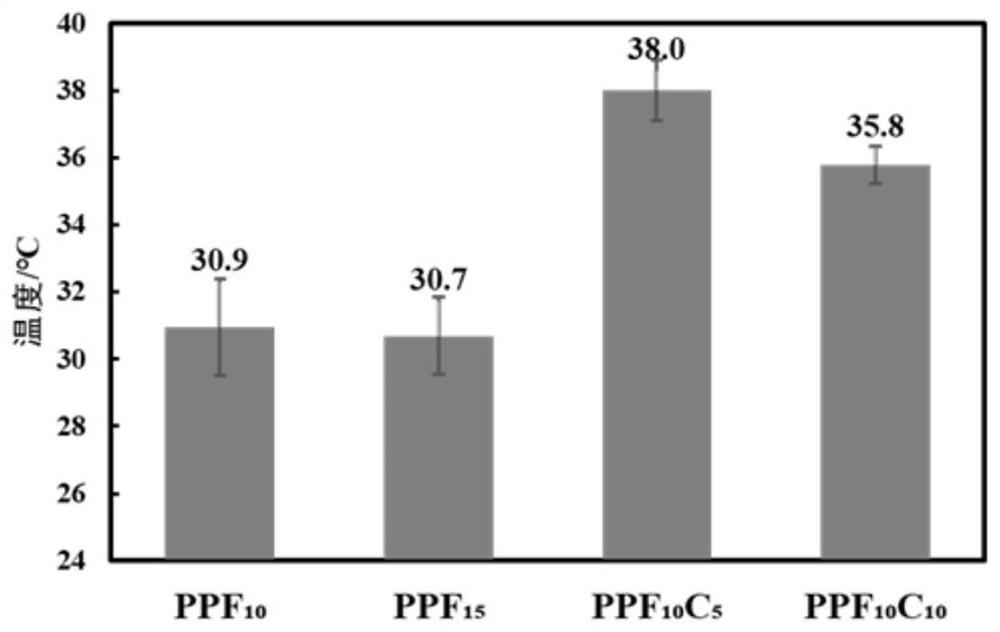

[0043] Embodiment 3: get 5.62g CTA-PDMS-CTA (0.95mmol), 22.22g NVP (200mmol), 4.21g FA (5.7mmol), 8.2mg AIBN (0.5mmol) are dissolved in 12mL 1,4-dioxane , was added to a dry round-bottomed flask, deoxygenated by bubbling nitrogen gas at room temperature for 30 min, then the flask was immersed in an oil bath preheated to 75 °C, reacted for 24 h under stirring, and then quenched with ice-water mixture . The reacted solution was concentrated and precipitated at least three times in ten volumes of cold ether, the solid was collected after filtration, and then dried in vacuum at 40°C overnight to obtain the amphiphilic polymer FA-PVP-PDMS-PVP-FA.

[0044] Dissolve 5.0g of PDMS (molecular weight: 320000), 0.5g of FA-PVP-PDMS-PVP-FA in a mixed solution of 3mL of dichloromethane and 5mL of tetrahydrofuran, mix well and add 0.125g of crosslinking agent METES and 50mg of catalyst DBTDL, Spread the solution evenly on a clean 20×20mm 2 On the surface of the steel sheet, the amphiphilic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com