A kind of anti-icing lubricating grease and its preparation method and application

A lubricating grease and anti-icing technology, which is applied in the field of anti-icing lubricating grease and its preparation, can solve the problems of easy contamination of the interface lubricating coating, increased ice adhesion strength, and inability to realize self-cleaning, etc., to achieve excellent antifouling , Improving rheology and lubricity, and excellent recoverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of unmodified grease: (1) Disperse 25g of fatty acid amide sodium salt in 65g of silicone oil, and stir continuously in a water bath at 70°C for 2 hours to obtain a mixed emulsion; (2) Mix 3g of trisodium phosphate antioxidant, 2g of ethyl alcohol Diaminetetraacetic acid tetrabenzylamide antioxidant, 3g naphthenic acid soap and 2g chlorotrifluoroethylene telomer were added to the mixed emulsion, and the water bath was heated to 110°C for 6 hours to obtain unmodified grease.

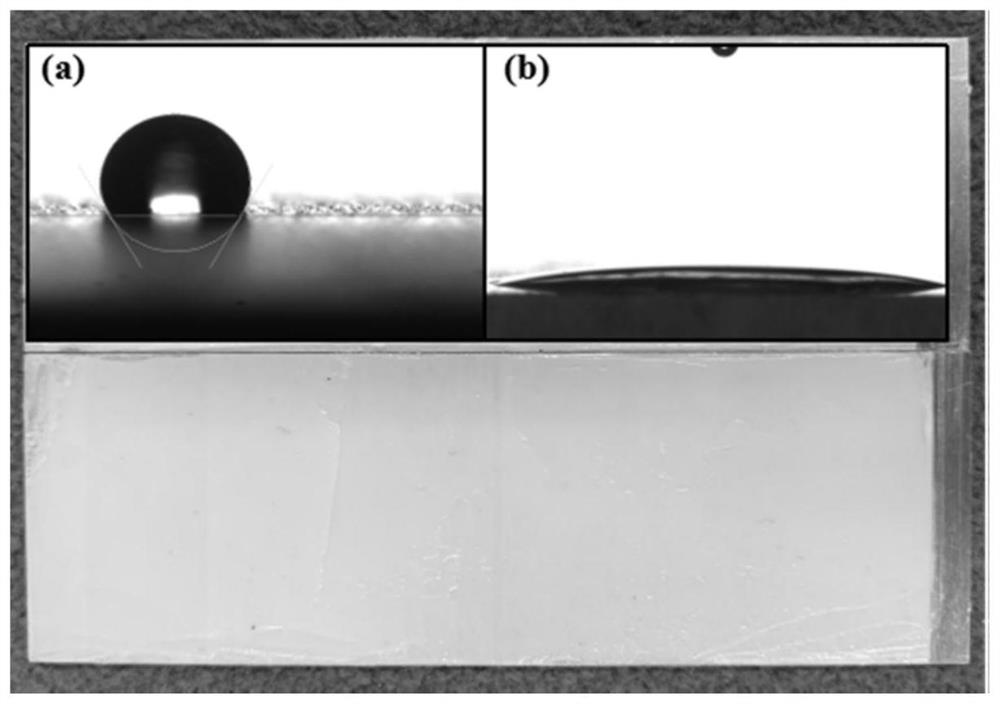

[0024] Preparation of anti-icing grease: (1) 1g of ST-OUP silica sol with a nanoparticle size of 40-100nm, a solid content of 15%, and a pH value of 4, 4mL of analytically pure ammonia water with a content of 38wt.%, 8mL of deionized water, Disperse 0.6mL TEOS and 0.6mL triethoxyoctylsilane in 80mL absolute ethanol, and stir continuously in a water bath at 50°C for 24 hours to obtain a superhydrophobic and superoleophilic coating; (2) place the superhydrophobic and superoleophilic coatin...

Embodiment 2

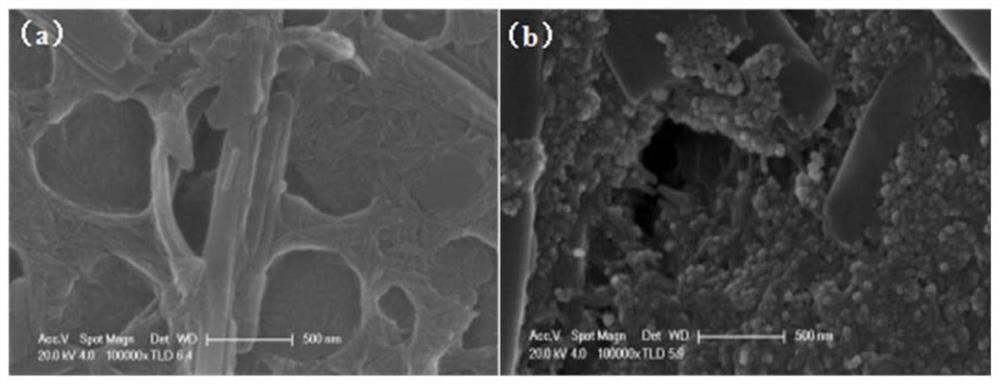

[0027] The anti-icing lubricating grease prepared in Example 1 and the traditional lubricating grease were degreased to compare and observe the similarities and differences in the microstructure of the two. The degreasing operation is as follows: evenly spread the grease sample on a thin aluminum sheet with a thickness of 3 μm, then put the aluminum sheet coated with the sample into a beaker filled with petroleum ether, seal it and let it stand for a period of time until the base in the grease The aluminum flakes were removed after the oil was dissolved in petroleum ether. After the sample was sprayed with gold, it was observed under a field emission scanning electron microscope, and the results were as follows: figure 2 shown. in, figure 2(a) is the SEM image of traditional grease, figure 2 (b) is the SEM image of the anti-icing grease. It can be seen from the comparison that the anti-icing grease fiber frame is coated with a large amount of superhydrophobic and supero...

Embodiment 3

[0029] The anti-icing lubricating grease prepared in embodiment 1 is carried out the test of ice adhesion strength when deicing under low temperature and ultra-low temperature environment:

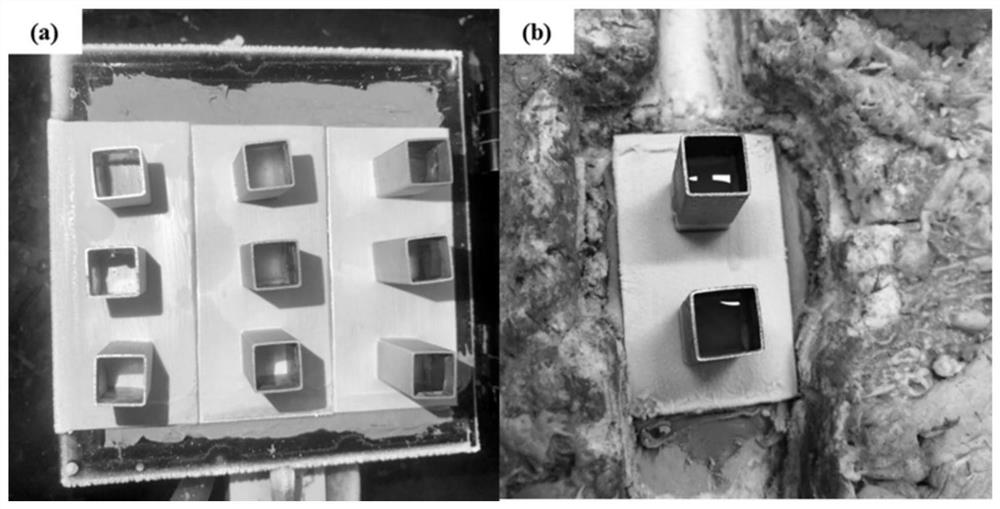

[0030] (1) Low temperature environment at -20°C: use a wire rod roller coating process to evenly coat a thin layer of anti-icing grease on the aluminum alloy surface with a thickness of 3 μm; the test process is as follows image 3 (a) shown.

[0031] (2) Ultra-low temperature environment at -150°C: use a brushing process to evenly coat a layer of anti-icing grease on the surface of the aluminum alloy with a thickness of 0.5mm; the test process is as follows image 3 (b) shown.

[0032] The test results are averaged after multiple tests. In the low temperature environment of -20℃, the ice adhesion strength of the unmodified grease is 21.7KPa when deicing, and the anti-icing grease is 7.6KPa, and the deicing performance is increased by 65.0%. The ice adhesion strength of the anti-icing g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com