Method for preparing powder-cored welding wire and cladding layer used for cladding surface of hot working die

A technology of hot work die and cladding layer, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problem of limited life extension effect, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1. Preparation of powder cored wire.

[0025] (1) Take the powder material according to the following proportioning: graphite carbon powder (purity 99.5%, particle size-300 mesh): 8wt.%, nickel (purity 99.5%, particle size-100 mesh): 29%, chromium (purity 99% , particle size-100 mesh): 26wt.%, molybdenum (purity 99.5%, particle size-300 mesh): 2wt.%, aluminum (purity 99%, particle size-200 mesh): 3%, titanium (purity 99.5%, particle size- 100 mesh): margin. The above powder was placed in a drying oven, dried at 110°C for 3 hours, and then the powder was ball milled in a ball mill for 4 hours to obtain a uniform and fine mixed powder.

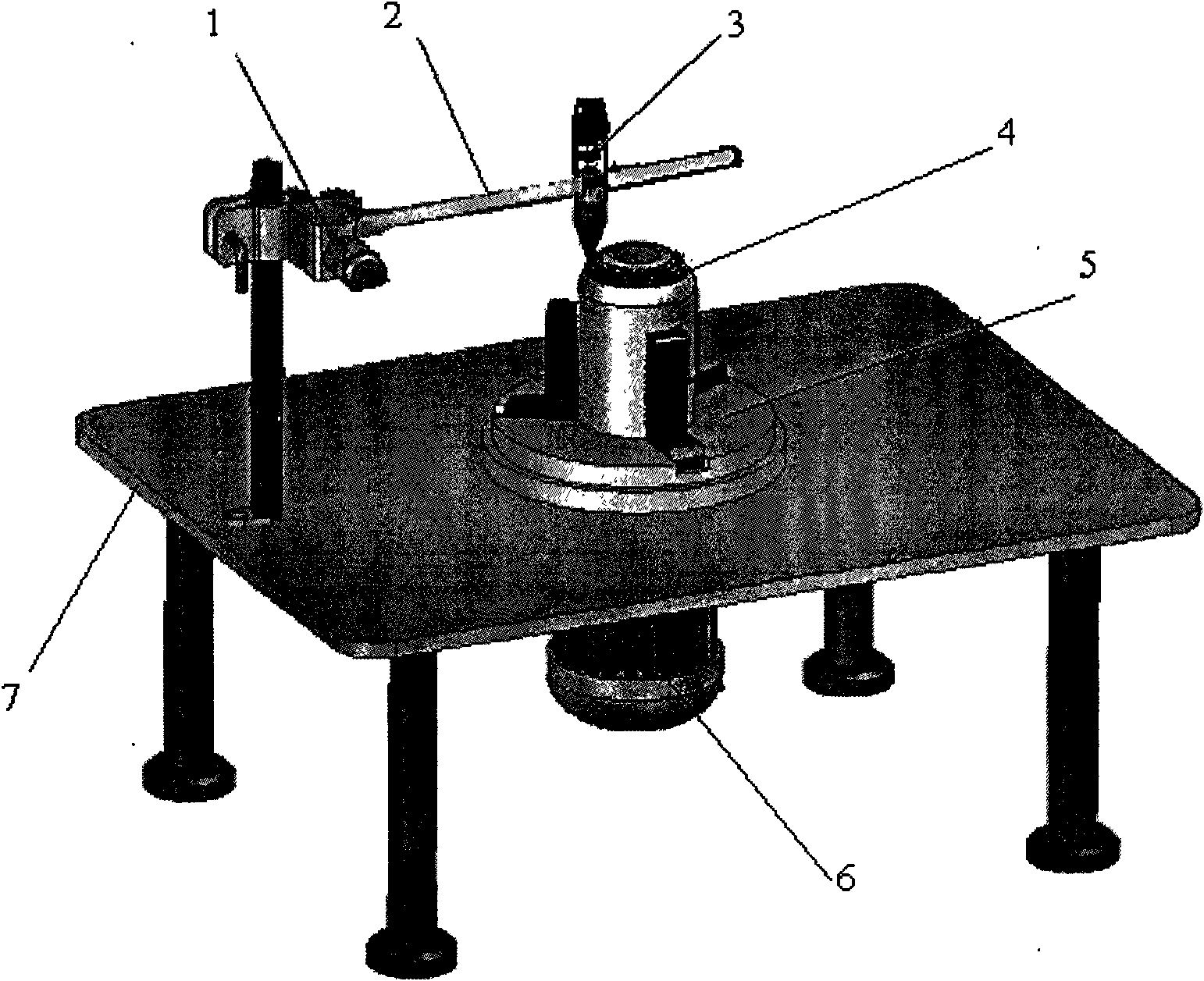

[0026] (2) Ni foil (99% in purity, 80 μm in thickness, 32 mm in width, and 350 mm in length) was selected as the skin material for wrapping the mixed powder. The mixed powder is wrapped in the nickel foil by using the wrapping mechanical device for preparing the powder cored wire, and the weight percentage of the mixed powder in the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com