Method for preparing seawater corrosion resistant cladding layer on steel matrix

A cladding layer and steel substrate technology, applied in the coating, metal material coating process, etc., can solve the problems of short anti-corrosion life, low bonding strength, low corrosion resistance of the coating, etc., to achieve long seawater corrosion resistance life, The effect of low preparation cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

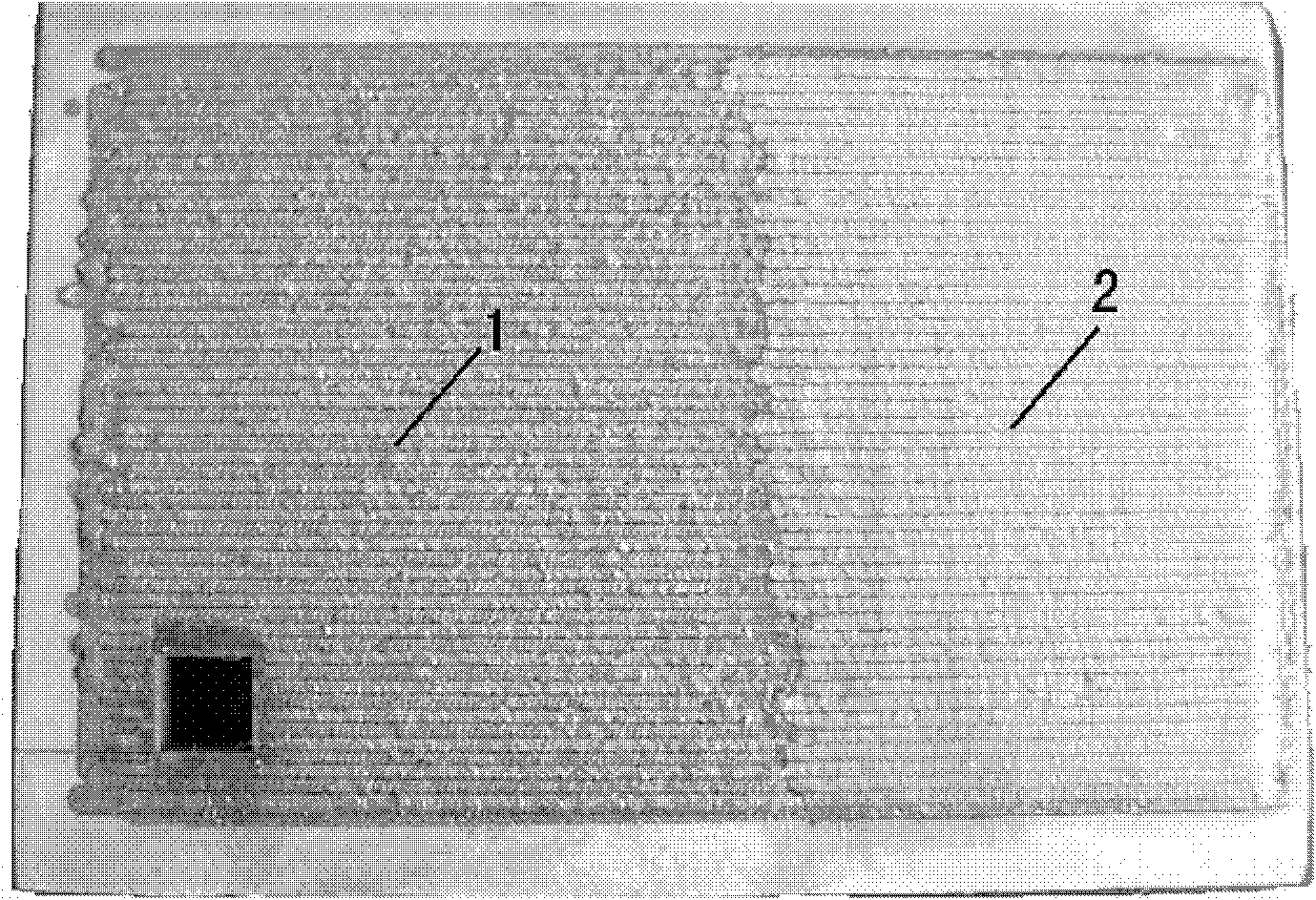

Image

Examples

Embodiment

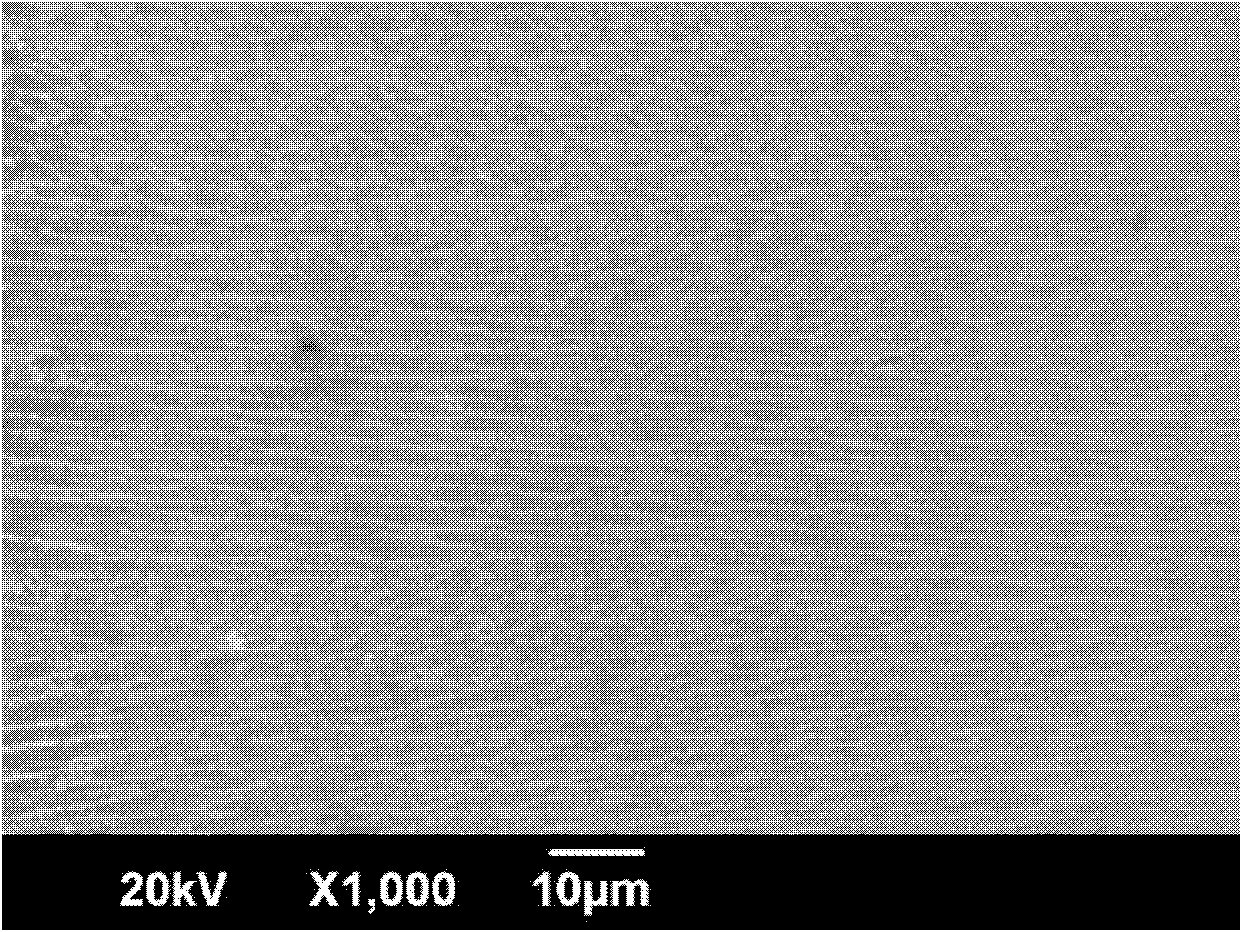

[0039] 1. Mixed powder for cladding

[0040] 1. Mixed powder raw material components

[0041] The weight percentages of the ingredients of the mixed powder are as follows:

[0042] Cr powder (particle size -200+300 mesh, purity 99.5%): 28wt.%; Mo powder (particle size -200+300 mesh, purity 99.6%): 13.5wt.%; W powder (particle size -200+300 mesh, purity 99.5%): 1wt.%; Nb powder (particle size+200-300 mesh, purity 99.5%): 0.5wt.%; Ni powder (particle size -200+300 mesh, purity 99.6%): balance.

[0043] 2. Preparation process of mixed powder

[0044] (1) According to the various powder ratios described in step 1, weigh the various powders required by the powder raw materials;

[0045] (2) Put the powdered raw materials into a drying box for drying, the temperature of the drying box is 120°C, and the drying time is 3 hours;

[0046] (3) Use a ball mill to mix the dried powder raw materials to form a mixed powder, and the mixing time is 3 hours;

[0047] (4) Seal the mixed powder in a plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com