Powdered material used for preparing high-temperature wear-resistant cladding layer and preparation method thereof

A powder material, high-temperature wear-resistant technology, applied in the field of surface engineering, to achieve the effects of low dilution rate, low preparation cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

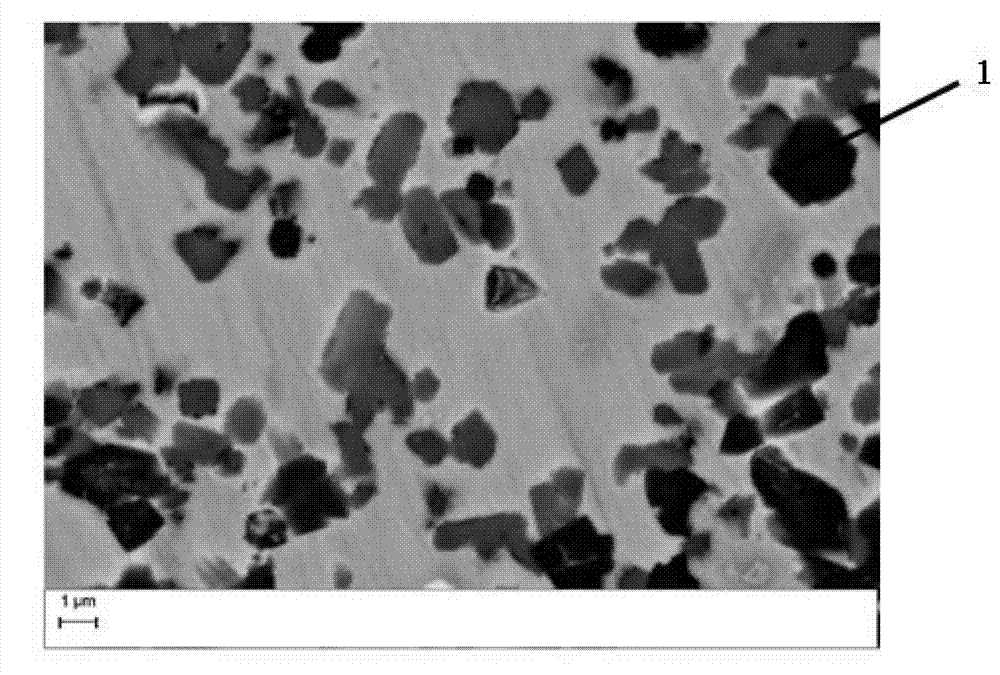

[0025] Embodiment: TiB is prepared on the heating surface of the water wall tube 2 Reinforced wear-resistant cladding layer

[0026] 1. Preparation of mixed powder

[0027] 1. Preparation of powder raw materials

[0028] The proportioning of described powder raw material is as follows:

[0029] TiB 2 Powder (grain size-200+350 mesh): 15 wt.%, Ni-Cr-Mo-Fe-Nb-B-Si-C alloy powder (grain size-140+325 mesh): balance; of which, Ni-Cr- The composition of Mo-Fe-Nb-B-Si-C alloy alloy powder is: Cr:24wt.%, Mo:1wt.%, Fe:3wt.%, Nb:0.6wt.%, B:3.5wt.%, Si: 3.7wt.%, C: 1wt.%, Ni: balance.

[0030] Ni-Cr-Mo-Fe-Nb-B-Si-C alloy powder was prepared by gas atomization method.

[0031] 2. Preparation process of mixed powder

[0032] (1) According to the various powder ratios described in step 1, weigh the various powders required for the powder raw materials;

[0033] (2) Put the powder raw material into a drying oven for drying, the temperature of the drying oven is 110°C, and the drying ...

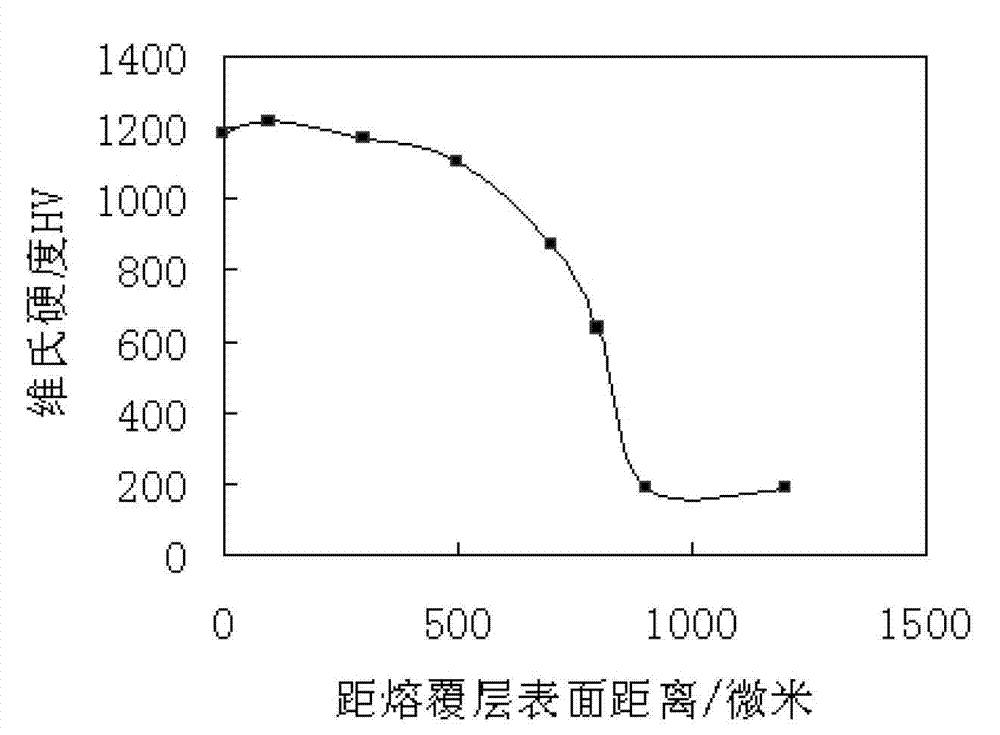

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com