Preparation method for wear-resisting metal ceramic composite material

A technology of composite materials and cermets, which is applied in the field of ceramic particle reinforced iron-based wear-resistant composite materials and its preparation, can solve the problems of strip-shaped fast unfavorable preparation of large and medium-sized wear-resistant parts, strip-shaped blocks are difficult to realize, and there are hidden dangers in use. , to achieve the effect of wide application range, high density and convenient demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

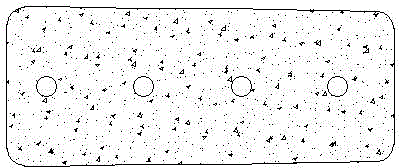

[0031] like figure 1 and figure 2 A kind of HP type grinding roller is shown a cermet wear-resistant composite material, and its preparation method comprises the following steps:

[0032] (1) Mix alumina ceramics with a particle size of 6-50 mesh or surface-pretreated alumina ceramics and iron-based alloy powder with polyvinyl alcohol to obtain a mixture, wherein alumina ceramics or surface-pretreated alumina The volume ratio of ceramics and iron-based alloy powder is 1:1, and the amount of polyvinyl alcohol added is 2% of the mass of ceramics;

[0033] (2) Fill the above mixture into the cavity of the press mold, place a 2~10mm ordinary steel gasket in advance at the bottom of the cavity, and the pressure of the press on the mixture is 50MPa. After molding and demoulding, put the blank together with the gasket Dry in a drying oven at 150°C for 2 hours;

[0034] (3) Put the dried biscuit together with the gasket into a vacuum furnace for sintering at a maximum temperat...

Embodiment 2

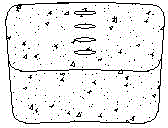

[0037] like image 3 and Figure 4 Another HP type grinding disc shown is a cermet wear-resistant composite material, and its preparation method includes the following steps:

[0038] (1) Mix tungsten carbide ceramics with a particle size of 6~50 mesh or tungsten carbide ceramics with surface pretreatment and nickel-based alloy powder with polyvinyl alcohol to obtain a mixture. Among them, tungsten carbide ceramics or tungsten carbide with surface pretreatment The volume ratio of ceramics and nickel-based alloy powder is 1:19, and the amount of polyvinyl alcohol added is 3% of the mass of ceramics;

[0039] (2) Fill the above mixture into the cavity of the press mold, place a 2~10mm ordinary steel gasket in advance at the bottom of the cavity, and the pressure of the press on the mixture is 70MPa. After molding and demoulding, put the blank together with the gasket Dry in a drying oven at 150°C for 2 hours;

[0040] (3) Put the dried biscuit together with the gasket int...

Embodiment 3

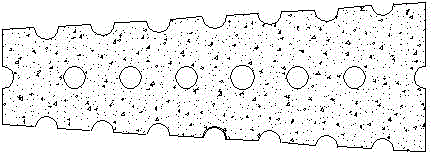

[0043] like Figure 5 and Image 6 A kind of preparation method of the metal-ceramic wear-resistant composite material of shown a kind of MPS type grinding roller, comprises the following steps:

[0044] (1) Mix zirconia ceramics with a particle size of 6-50 mesh or zirconia ceramics with surface pretreatment and iron-based alloy powder with polyvinyl alcohol to obtain a mixture. Among them, zirconia ceramics or zirconia ceramics with surface pretreatment The volume ratio of ceramics and iron-based alloy powder is 1:10, and the amount of polyvinyl alcohol added is 1% of the mass of ceramics;

[0045] (2) Fill the above mixture into the cavity of the press mold, place a 2~10mm ordinary steel gasket in advance at the bottom of the cavity, and the pressure of the press on the mixture is 60MPa. After molding and demoulding, put the blank together with the gasket Dry in a drying oven at 150°C for 2 hours;

[0046] (3) Put the dried biscuit together with the gasket into a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com