Method for electrodepositing chromium and chromium alloy composite coating through ultrasound-pulse for trivalent chromium plating liquid system

A pulse electrodeposition and composite coating technology, which is applied in coatings, electrolytic coatings, etc., can solve the problems of high pollution, high toxicity, and high energy consumption in the hexavalent chromium electroplating process, and achieve strong bonding, reduce environmental pollution, and bright coatings Dense and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Take an ordinary brass sample with a size of 40mm×20mm×2mm, using 2 # 、4 # 、6 # Metallographic sandpaper was polished in turn, washed with tap water; then washed with alcohol and acetone solution, and then washed in H 2 SO 4 40-100ml / l, HCl 40-70g / l activation solution, temperature 20-40°C, activate for 2-3 minutes, and the pretreated sample to be plated can be obtained.

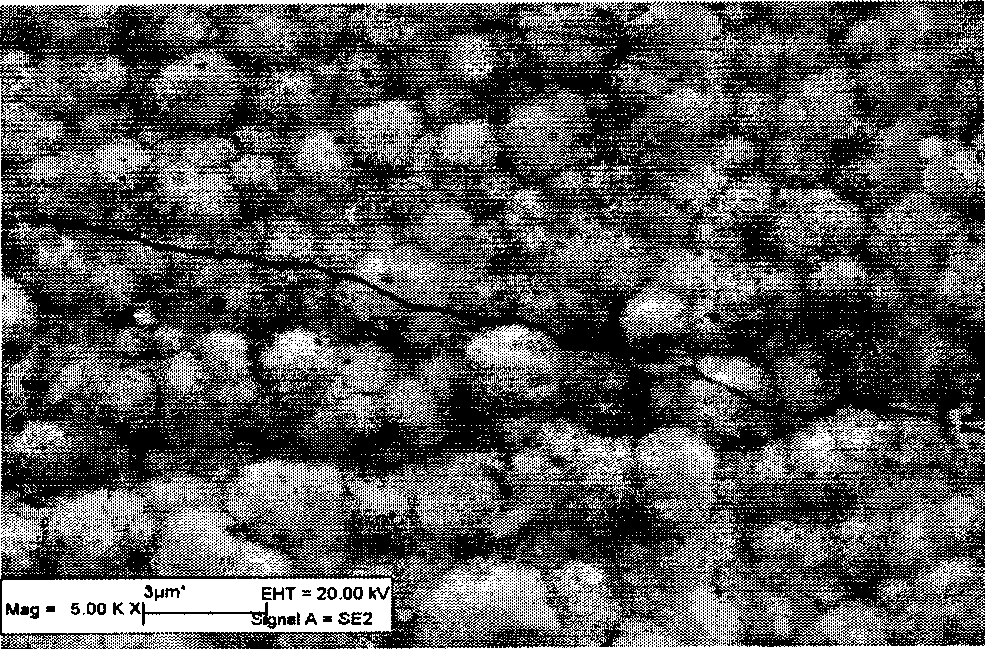

[0028] 2) Take the pretreated sample to be plated as the cathode and the insoluble anode (graphite) as the anode. Under the condition of stirring, directly insert the 3 ·6H 2 O 0.6mol L -1 , SiC 30g·L -1 , trisodium citrate 0.6mol L -1 , sodium oxalate 0.3mol L -1 , CH 3 COONa0.1mol L -1 , CO(NH 2 ) 2 2.0mol·L -1 , Cr 2 (SO 4 ) 3 ·6H 2 O0.1mol L -1 , H 3 BO 3 0.72mol·L -1 , NaCl 2.0mol·L -1 In the plating solution, the temperature of the plating solution is 35°C, and the current density is 8A·dm -2 , the pH of the plating solution is 2.0, the pulse working ratio is 0.8, the...

Embodiment 2

[0030] 1) The pretreatment of the plated part is the same as "Example 1".

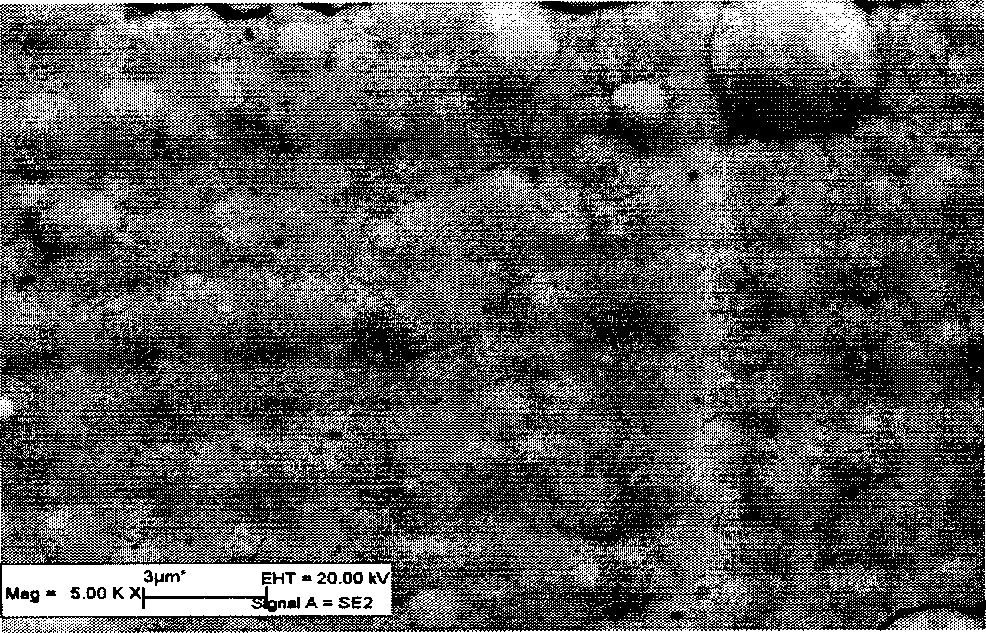

[0031] 2) Take the pretreated sample to be plated as the cathode and the insoluble anode (graphite) as the anode. Under the condition of stirring, directly insert the 3 ·6H 2 O 0.6mol L -1 , NiSO 4 ·6H 2 O 0.075mol L -1 , SiC 50g·L -1 , trisodium citrate 0.5mol L -1 , sodium oxalate 0.4mol L -1 , CH 3 COONa 0.1mol L -1 , CH 3 CH(OH) COOH 0.1mol L -1 , CO(NH 2 ) 2 2.0mol·L -1 , Cr 2 (SO 4 ) 3 ·6H 2 O 0.1mol L -1 , H 3 BO 3 0.72mol·L -1 , NaCl 2.0mol·L -1 In the plating solution, the temperature of the plating solution is 35°C, and the current density is 8A·dm -2 , the pH of the plating solution is 2.0, the pulse working ratio is 0.7, the reversing time is 2ms, the pulse frequency is 50Hz, the ultrasonic power is 45W, the ultrasonic frequency is 80KHz, and the pulse electrodeposition time is 70min, the Cr-Ni / SiC composite Coating sample, the thickness of the coating is about 15....

Embodiment 3

[0033] 1) The pretreatment of the plated part is the same as "Example 1".

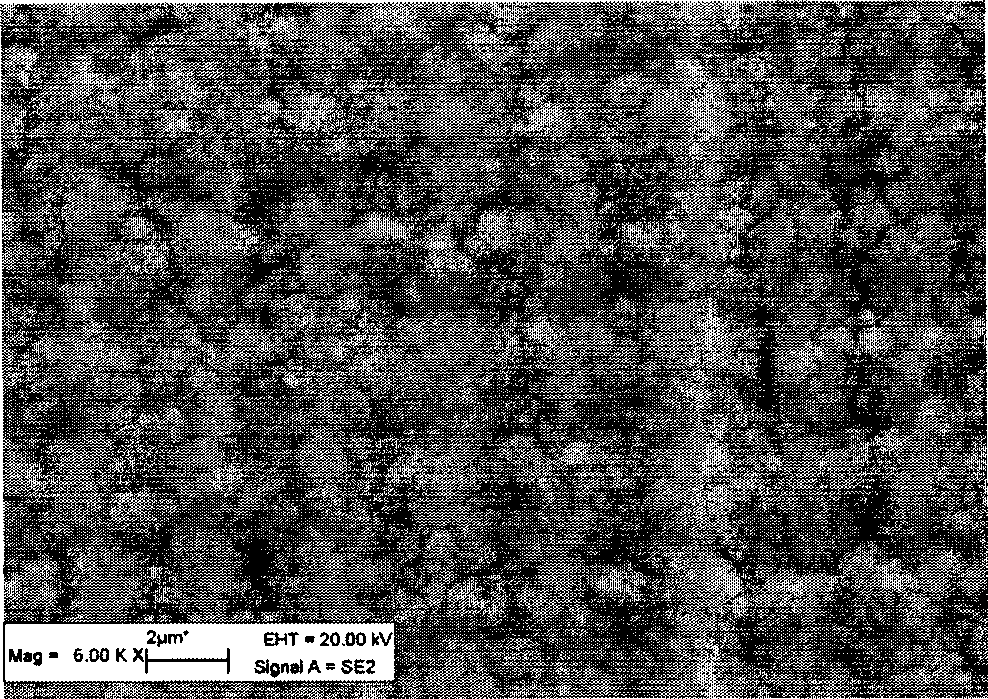

[0034] 2) Take the pretreated sample to be plated as the cathode and the insoluble anode (graphite) as the anode. Under the condition of stirring, directly insert the 3 ·6H 2 O 0.6mol L -1 , FeSO 4 ·7H 2 O 0.05mol L -1 , SiO 2 40g·L -1 , trisodium citrate 0.5mol L -1 , sodium oxalate 0.4mol L -1 , CH 3 COONa 0.1mol L -1 , CO(NH 2 ) 2 2.0mol·L -1 , Cr 2 (SO 4 ) 3 ·6H 2 O 0.1mol L -1 , H 3 BO 3 0.72mol·L -1 , NaCl 2.0mol·L -1 In the plating solution, the temperature of the plating solution is 35°C, and the current density is 8A·dm -2 , the pH of the plating solution is 1.5, the pulse working ratio is 0.3, the reversing time is 2ms, the pulse frequency is 50Hz, the ultrasonic power is 100W, and the ultrasonic frequency is 60KHz. The pulse electrodeposition time is 40min, and the Cr-Fe / SiO 2 Composite coating sample, the thickness of the coating is about 13.81 μm, and the SiO in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com