Abrasion-resistant steel for low-alloy ultra-high strength engineering machine and preparation method thereof

An ultra-high-strength, engineering machinery technology, applied in the field of iron-based alloys, can solve problems such as increased user costs and easy wear, and achieve the effects of inhibiting grain growth, increasing nucleation points, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The chemical composition of the wear-resistant steel of this embodiment is calculated by mass percentage: C: 0.34%, Si: 0.78%, Mn: 1.57%, Cr: 1.24%, Mo: 0.45%, V: 0.073%, Ti: 0.026% , S: 0.0035%, P: 0.0064%, B: 0.0013%, N: 0.0032%, the rest is Fe and unavoidable impurities.

[0049] Smelt molten steel according to the above ingredients, and then cast it into a slab, forge the slab into a size of 420×70×60 (mm), then heat the slab to 1280°C and keep it for 2 hours, using two-stage controlled rolling, starting at 1080°C Carry out rough rolling, control the intermediate billet temperature above 1000℃, and the cumulative reduction rate of rough rolling is 52%; then carry out finishing rolling at 900℃~940℃, and control the final rolling temperature at 860℃~880℃, and the cumulative reduction ratio of finishing rolling 31%, the obtained steel plate thickness is 20mm.

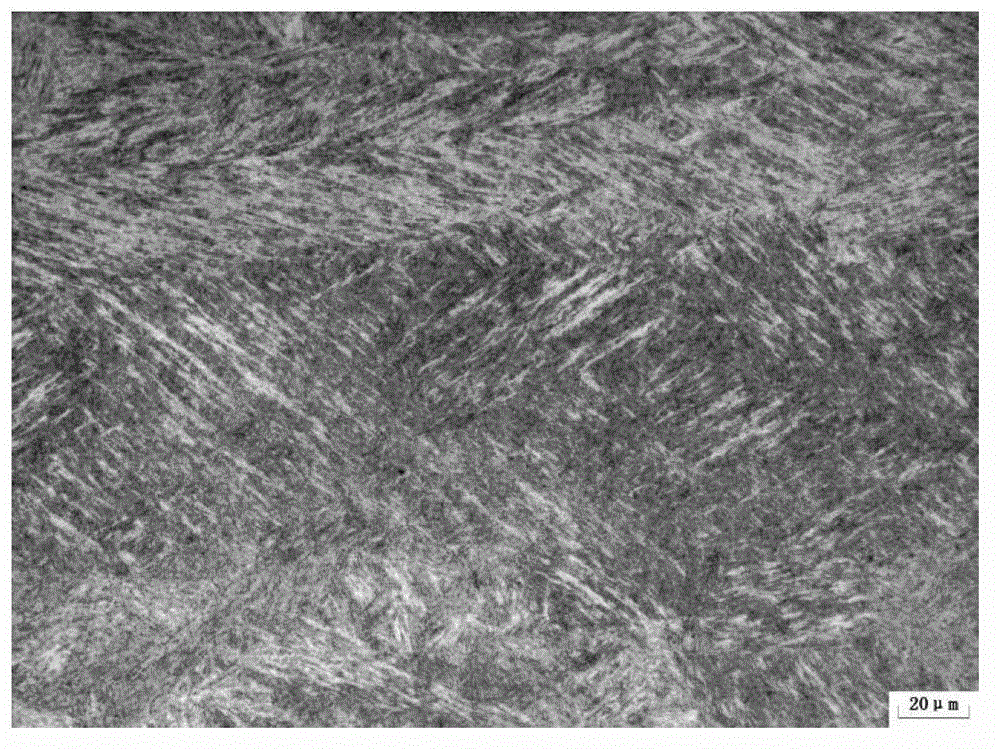

[0050] After rolling into a steel plate, it is directly quenched and tempered at 250°C for 1.5 hours, and then ai...

Embodiment 2

[0053] The chemical composition of the wear-resistant steel of this embodiment is the same as that of embodiment 1.

[0054] Smelt molten steel according to the above ingredients, then cast it into a slab, forge the slab into a size of 320×70×60 (mm), then heat the slab to 1280°C and keep it for 2 hours, using two-stage controlled rolling, starting at 1080°C Carry out rough rolling, control the intermediate billet temperature above 1000℃, the cumulative reduction rate of rough rolling is 58.3%; then carry out finishing rolling at 900℃~940℃, control the final rolling temperature at 860℃~880℃, and the cumulative reduction ratio of finishing rolling 52%, the thickness of the obtained steel plate is 12mm.

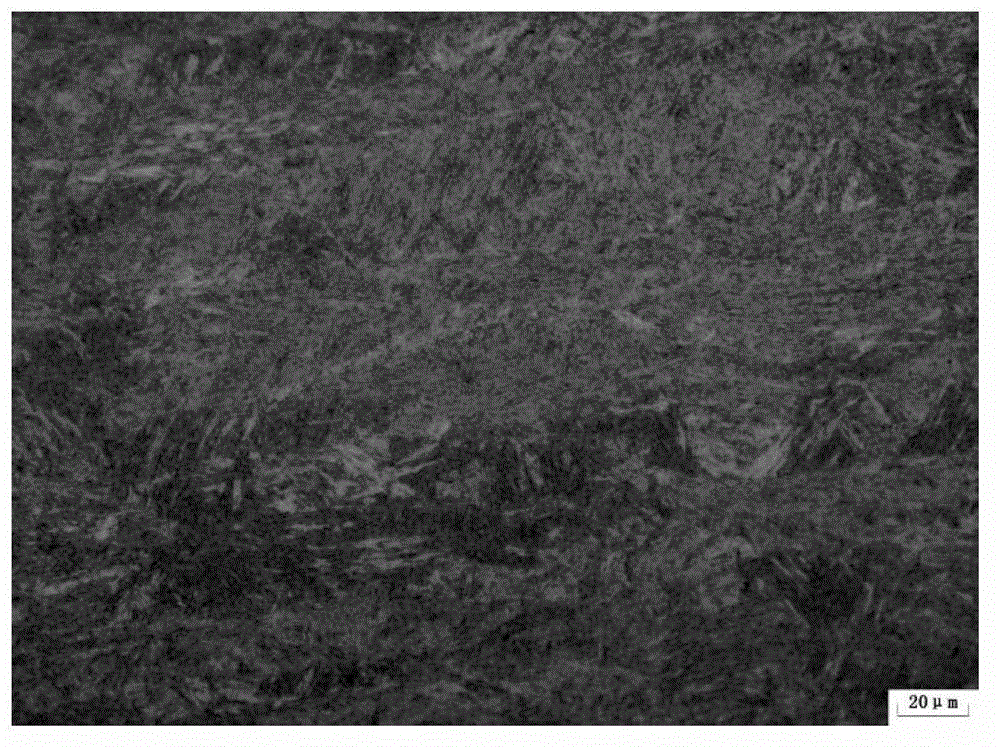

[0055] The heat treatment process is the same as in Example 1, to obtain low-alloy ultra-high-strength wear-resistant steel for construction machinery, and its structure is as figure 2 As shown, the metallographic structure is a tempered martensite structure.

[0056] The tensile st...

Embodiment 3

[0058] The chemical composition of the wear-resistant steel of this embodiment is calculated by mass percentage: C: 0.33%, Si: 0.47%, Mn: 1.61%, Cr: 2.18%, Mo: 0.44%, V: 0.048%, Ti: 0.019% , S: 0.0029%, P: 0.0059%, B: 0.0008%, N: 0.0034%, the rest is Fe and inevitable impurities.

[0059] The molten steel is smelted according to the above composition, and then poured into a slab. The slab is forged to a size of 420×70×60 (mm). The rolling process is the same as that of Example 1, and the thickness of the steel plate is 20mm.

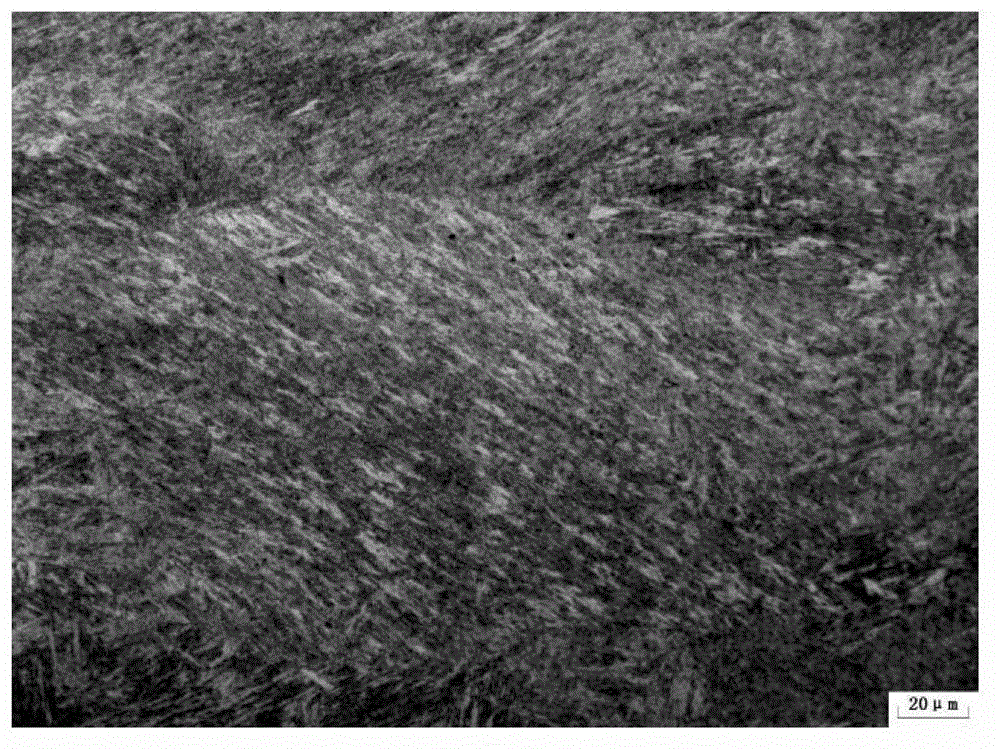

[0060] The heat treatment process is the same as in Example 1, to obtain low-alloy ultra-high-strength wear-resistant steel for construction machinery, and its structure is as image 3 As shown, the metallographic structure is a tempered martensite structure.

[0061] The tensile strength R of the wear-resistant steel product of this embodiment m 1739MPa, yield strength R p0.2 1392MPa, elongation after breaking A 5 11%, the reduction of area Z is 47%, the longi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com