Wear and corrosion resistant iron-based alloy laser-cladding petroleum drill stem joint

A technology of oil drill pipe joints and laser cladding, which is applied in the direction of drill pipes, drill pipes, earthwork drilling and mining, etc. It can solve the problems of easy slipping of the clamping part of the pipe clamp, complex composite process, and inability to handle locally, and achieves the degree of automation High, high laser energy density, uniform and fine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

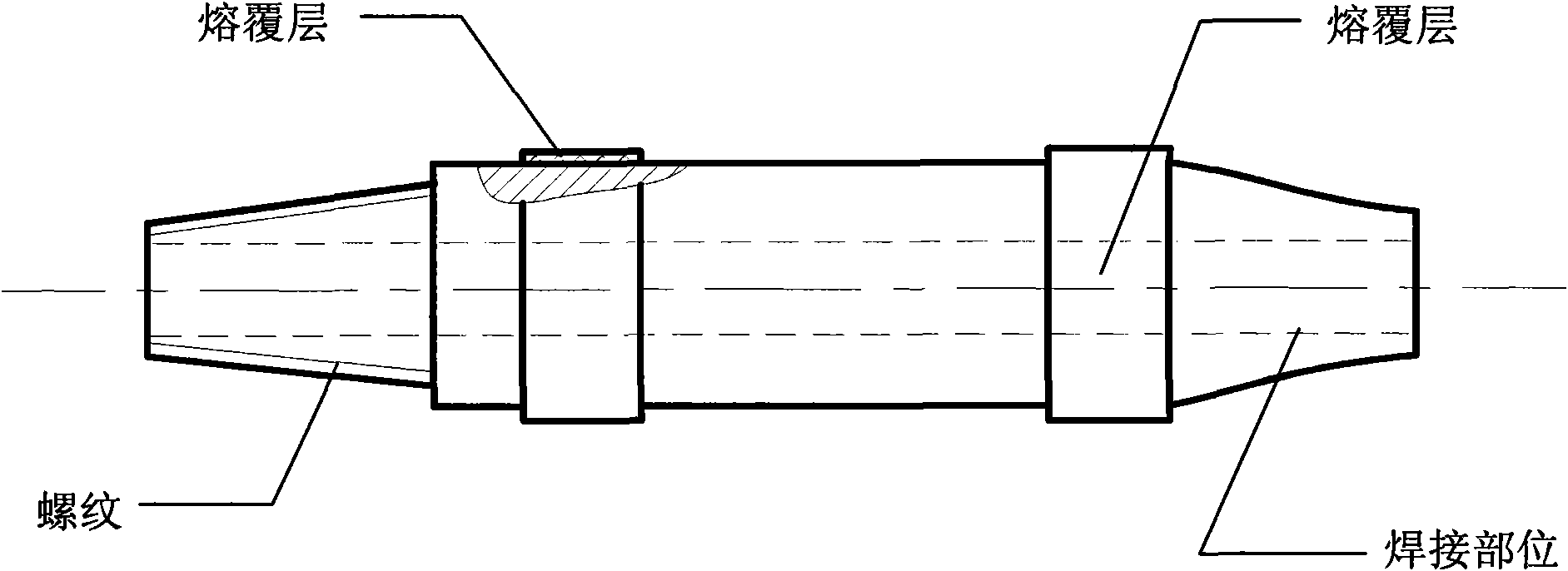

[0031] Carry out laser cladding treatment on the drill pipe joint, which is carried out in the following steps:

[0032] (1) Wipe the surface of the drill pipe joint to be treated with acetone to completely remove the oil.

[0033] (2) Put the drill pipe joint on the rotary table, and use the gravity powder feeder to adjust it to a suitable powder feeding rate of 15-30g / min.

[0034] (3) Scan the surface with a laser while feeding the powder. The process parameters for laser cladding are: laser power 3-4kW, scanning speed 200-300mm / min, and overlapping rate 20-30%. The specific components of the iron-based alloy powder are as follows: C, 0.1-1.5; Cr, 10-30; Ni, 1-10; Mn, 0.2-3.0; Mo, 0.1-3.0; Si, 1.0- 2.5; B, 0.1-3.5; the balance is iron, and the sum of its weight is 100%.

[0035] (4) After the drill pipe joint is naturally cooled to room temperature, the surface is cleaned and inspected.

[0036] The surface of the drill pipe joint has a layer of laser cladding wear-resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com