Low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and production method thereof

An interstitial-free, cold-rolled steel sheet technology, applied in the field of iron-based alloys, can solve the problems of rib formation, increased annealing furnace construction, maintenance costs, energy consumption, and high recrystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

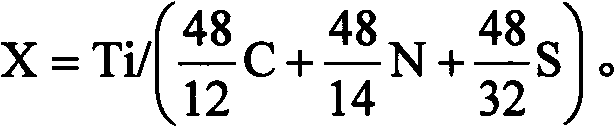

[0048] The low-temperature continuous annealing interstitial-free cold-rolled steel sheet of this specific embodiment is divided into four embodiments according to its composition and content. The composition and mass percentage content of the cold-rolled steel sheet of the four embodiments are shown in Table 1:

[0049] Composition and mass percentage content during table 1 cold-rolled steel plate steelmaking

[0050]

[0051] The production methods of cold-rolled steel sheets in the four embodiments of this specific embodiment include a steelmaking process, a hot rolling process, a cold rolling process and a continuous annealing process.

[0052] The steelmaking process includes: pre-desulfurization of molten iron, combined top-bottom blowing of converter, heating of LF furnace and ensuring bottom-blown Ar stirring time of more than 5 minutes, vacuum cycle degassing treatment of RH furnace, ensuring pure RH degassing time of more than 15 minutes, Then low-carbon steel mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com