Low-loss LiZn ferrite material for phase shifter and preparation method thereof

A ferrite material, low loss technology, applied in the preparation of high saturation magnetization LiZn ferrite material, the field of ferrite material preparation, can solve the problem of not given parameters, to reduce dielectric loss, low distortion Coercive force, the effect of improving the resistivity of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

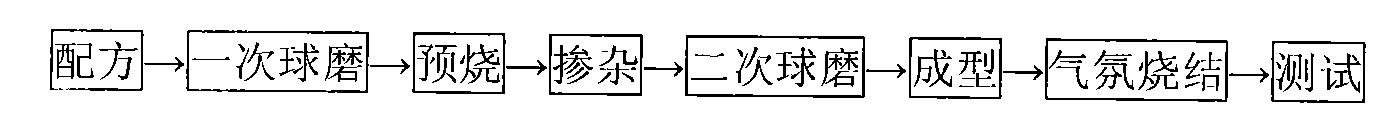

[0035] As an embodiment of the preparation method, the phase shifter of the present invention uses a low-loss high saturation magnetization LiZn ferrite material preparation method comprising the following steps:

[0036] (1) Formula

[0037] Using 64~71mol% Fe 2 o 3 , 15-22mol% ZnO, 0.8-1.5mol% Mn 3 o 4 , 9.9~12mol% Li 2 CO 3 ;

[0038] (2) Ball milling once

[0039] Grind the above powder in a planetary ball mill with a steel ball for 1 to 3 hours to mix the powder evenly;

[0040] (3) pre-burning

[0041] Pre-burn the ball abrasive obtained in step 2 in a furnace at 760-850°C for 1-3 hours;

[0042] (4) Doping

[0043] Add the following additives to the powder obtained in step 3 by weight: 0.5-3.0wt% Bi 2 o 3 , 0.1~0.5wt% BST, 0.05~0.4wt% Nb 2 o 5 ;

[0044] (5) Secondary ball milling

[0045] The powder obtained in step 4 is milled with steel balls for 2 to 6 hours in a planetary ball mill;

[0046] (6) Molding

[0047] Add 8-15wt% organic binder to the p...

Embodiment 5

[0108] 1. Formula

[0109] Using 68.5mol% Fe 2 o 3 , 19.1mol% ZnO, 11.1mol% Li 2 CO 3 , 1.3 mol% Mn 3 o 4 ;

[0110] 2. One ball milling

[0111] Grind the above powder in a planetary ball mill with a steel ball for 1.5 hours to mix the powder evenly;

[0112] 3. Pre-burning

[0113] Pre-fire the ball abrasive obtained in step 2 in a furnace at 800°C for 1.5 hours;

[0114] 4. Doping

[0115] Add the following additives to the powder obtained in step 3 by weight: 3.0wt% Bi 2 o 3 , 0.2wt% BST, 0.1wt% Nb 2 o 5 ;

[0116] 5. Secondary ball milling

[0117] The powder obtained in step 4 was milled with steel balls for 2 hours in a planetary ball mill;

[0118] 6. Forming

[0119] Add 15wt% organic binder to the powder obtained in step 5 by weight, mix evenly, and after granulation, press the granular powder into a blank on a press;

[0120] 7. Atmosphere sintering

[0121] The blank obtained in step 6 was sintered in an atmosphere sintering furnace at a temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com