High-saturation-magnetization iron-base amorphous nanocrystal soft magnetic alloy and preparation method thereof

A nanocrystalline soft magnetic and magnetization technology, applied in the direction of magnetic materials, manufacturing tools, magnetic objects, etc., can solve the deterioration of soft magnetic properties, the decline of the amorphous formation ability of nanocrystalline alloy precursors, and the difficulty in preparing amorphous strips, etc. problem, to achieve the effect of increasing Fe content and increasing saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

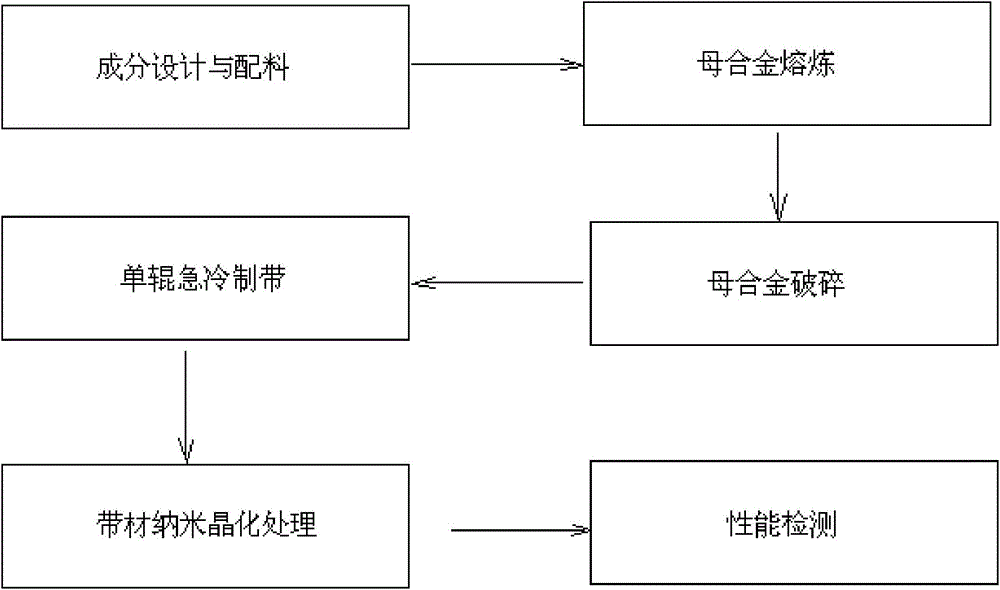

[0016] Such as figure 1 As shown, ferrosilicon, ferroboron, ferrophosphorus, iron, copper, aluminum and other raw materials are configured in a certain proportion as Fe 85 al 1 Cu 0.5 Si 3.5 B 6 P 4 The masterbatch is 5 kg in total; the prepared masterbatch is added to the crucible of the vacuum intermediate frequency induction furnace for melting, and the intermediate frequency induction melting is carried out 4 times to obtain an alloy ingot with uniform composition; the alloy ingot is mechanically crushed and put into the quartz tube of the quenching belt making equipment In the process, induction heating and melting were adopted, and a single-roller quenching strip process was used to make strips at a speed of 35m / s in the air to obtain an amorphous thin strip with a strip width of 10mm and a thickness of 30 microns; the amorphous alloy strip Put into tube type vacuum heat treatment furnace, vacuum degree is at 10 -3 Around pa, raise the temperature to 360°C at a hea...

Embodiment 2

[0018] Ferro-silicon, ferro-boron, ferro-phosphorus, iron, copper, aluminum, titanium and other raw materials are configured in a certain proportion as Fe 82 al 1 Ti 0.5 Cu 0.5 Si 4 B 8 P 4 The masterbatch is 5 kg in total; the prepared masterbatch is added to the crucible of the vacuum intermediate frequency induction furnace for melting, and the intermediate frequency induction melting is carried out 4 times to obtain an alloy ingot with uniform composition; the alloy ingot is mechanically crushed and put into the quartz tube of the quenching belt making equipment In the process, induction heating and melting were adopted, and a single-roller quenching strip process was used to make strips at a speed of 30m / s in the air to obtain an amorphous thin strip with a strip width of 20mm and a thickness of 30 microns; the amorphous alloy strip Put into tube type vacuum heat treatment furnace, vacuum degree is at 10 -3 Around pa, raise the temperature to 360°C at a heating rate...

Embodiment 3

[0020] Ferro-silicon, ferro-boron, ferro-phosphorus, iron, copper, aluminum and other raw materials are configured in a certain proportion as Fe 79 Cr 1.5 mn 1.5 Cu 1.5 Si 5 8 7.5 P 4 The masterbatch is 5 kg in total; the prepared masterbatch is added to the crucible of the vacuum intermediate frequency induction furnace for melting, and the intermediate frequency induction melting is carried out three times to obtain an alloy ingot with uniform composition; the alloy ingot is mechanically crushed and put into the quartz tube of the quenching belt making equipment In the process, induction heating and melting were adopted, and a single-roller quenching strip process was used to make strips at a speed of 35m / s in the air to obtain an amorphous thin strip with a strip width of 25mm and a thickness of 30 microns; the amorphous alloy strip Put into tube type vacuum heat treatment furnace, vacuum degree is at 10 -3 Around Pa, raise the temperature to 360°C at a heating rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com