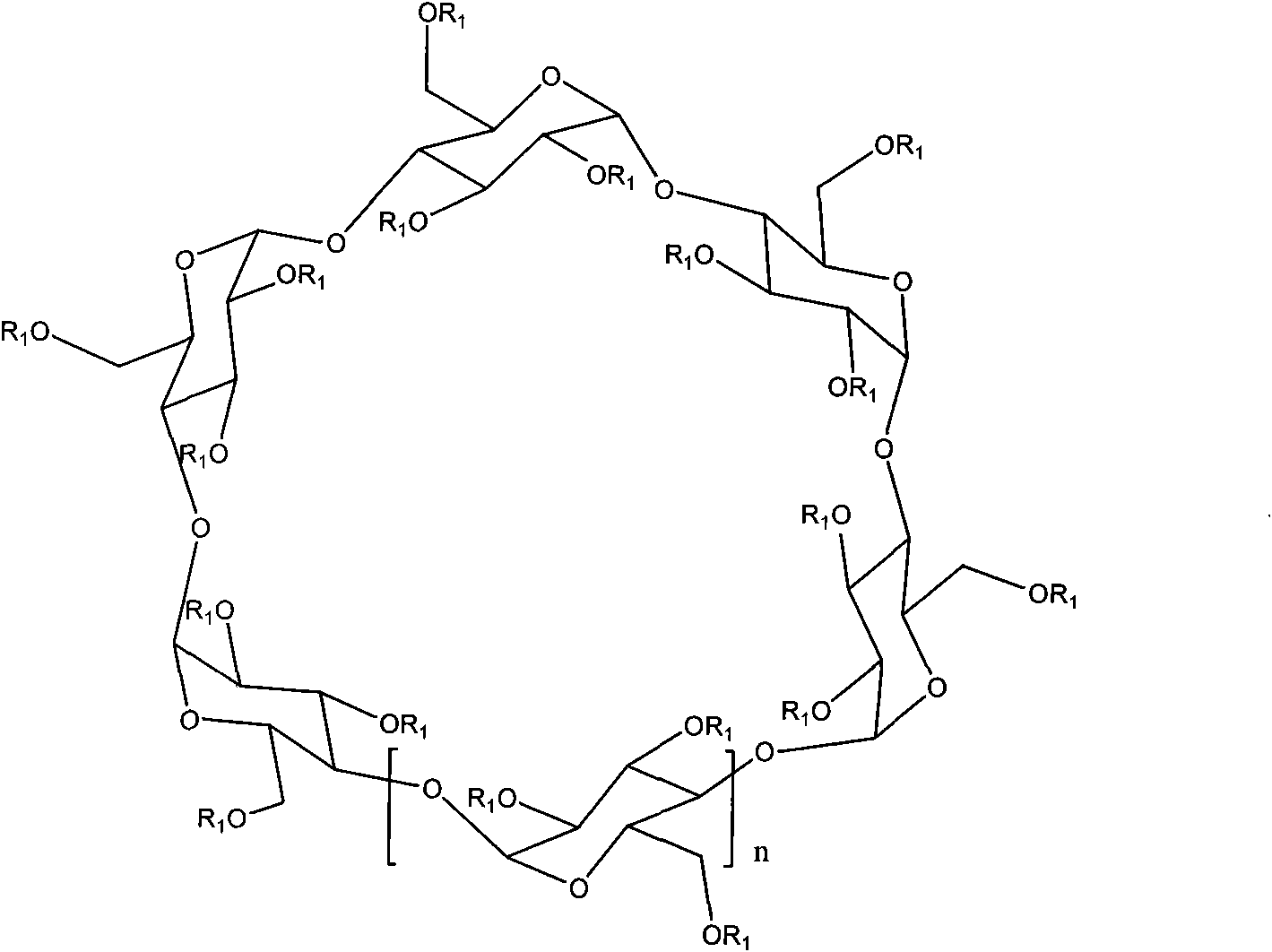

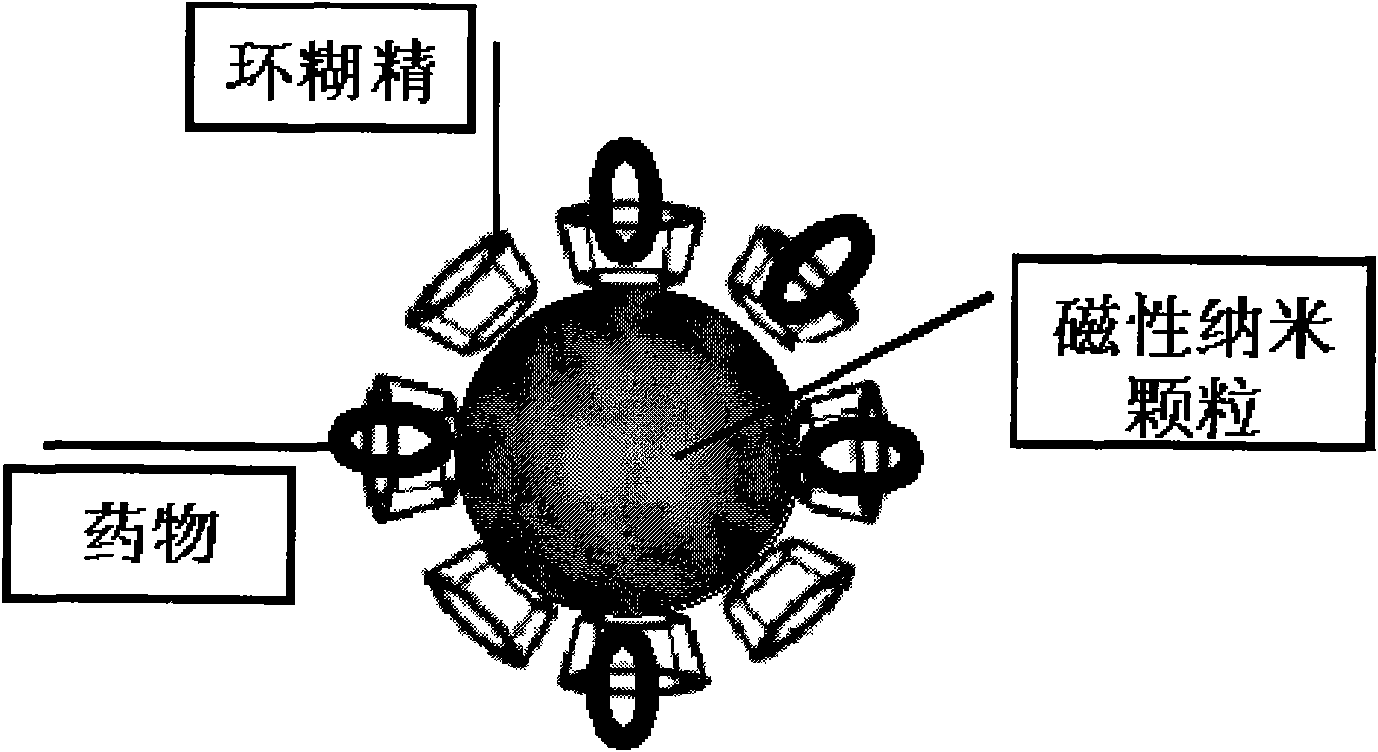

Preparation method of superparamagnetic cyclodextrin composite particles

A composite particle, superparamagnetic technology, applied in the direction of diamagnetic/paramagnetic materials, organic materials/organic magnetic materials, medical preparations with inactive ingredients, etc. and other problems, to achieve the effect of simple post-processing and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

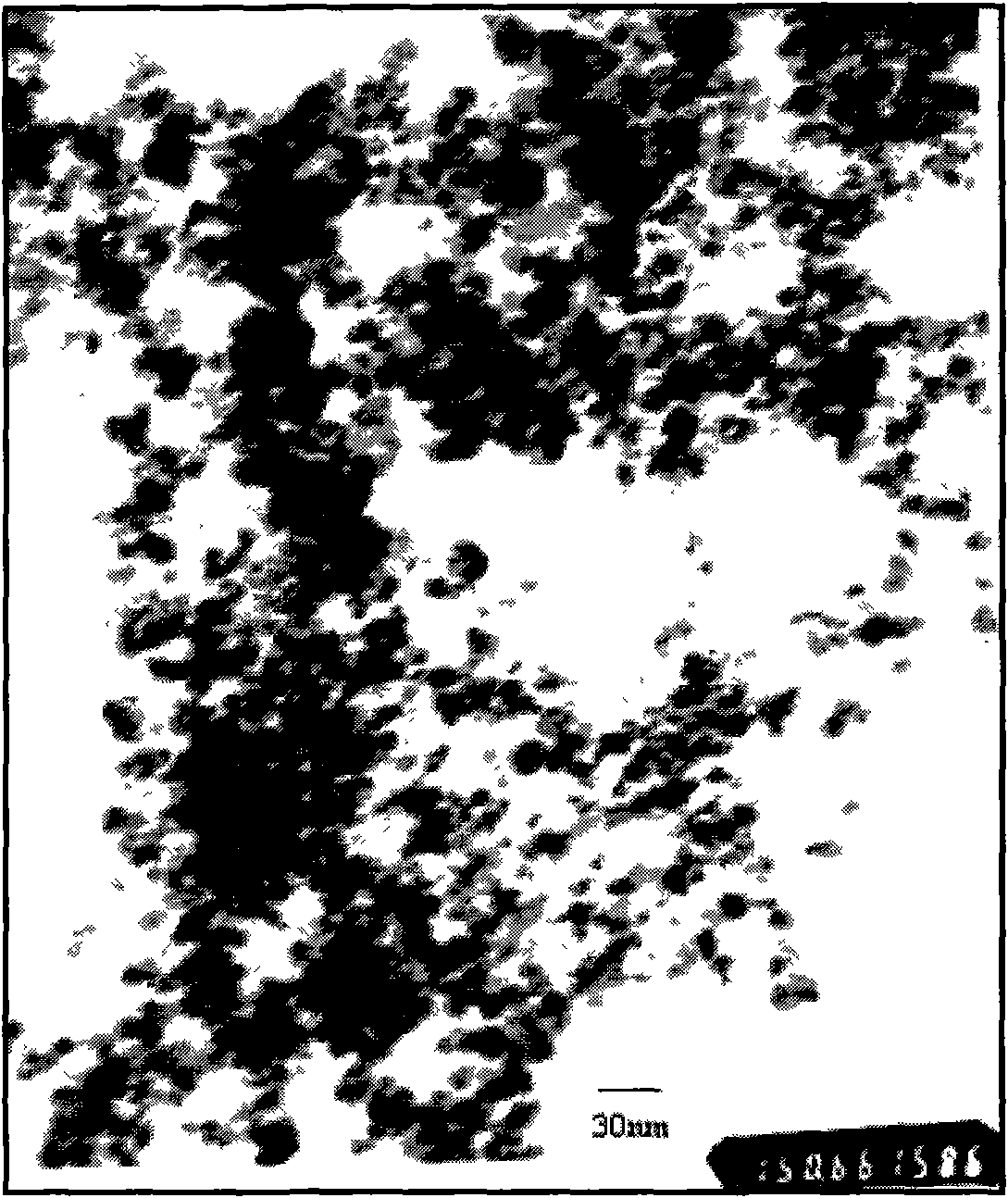

Embodiment 1

[0035] Add 3 milliliters of distilled water to a 50 milliliter round-bottomed flask containing 0.2104 g of magnetic ferric ferric oxide solid powder obtained by the co-precipitation method to obtain a magnetic nanoparticle mixed system containing a small amount of water. After adding 0.7009 grams of α-cyclodextrin and 1.6 milliliters of ammonia solution to the mixed system, 100 watts of ultrasonic dispersion was used for 5 minutes to obtain a uniform dispersion system with pH = 12. The temperature of the reaction system was increased to 40 ° C, and Hold at temperature for 3 hours. After the reaction is finished, it is repeatedly washed by means of magnetic separation, centrifugation or dialysis until the solution becomes neutral, and superparamagnetic α-cyclodextrin composite particles are obtained.

Embodiment 2

[0037] Pipette 300 mg of magnetic ferric oxide aqueous solution, discard the supernatant after magnetic separation, add 2.7 ml of water, 581.2 mg of hydroxypropyl-β-cyclodextrin and 1.2 ml of ammonia solution, and disperse with 100-watt ultrasonic for 20 minutes Afterwards, a uniform dispersion system with pH=13 was obtained, and the temperature of the reaction system was raised to 50° C. and kept at this temperature for 6 hours. After the reaction is finished, it is repeatedly washed by magnetic separation, centrifugation or dialysis until the solution becomes neutral, and then superparamagnetic hydroxypropyl-β-cyclodextrin composite particles are obtained.

Embodiment 3

[0039] Pipette co-precipitation method to obtain 5.53 ml of magnetic ferric ferric oxide fluid (solid content 36.2 mg / ml) in a 50 ml round bottom flask, place on a magnet to separate until the upper layer is clear, and discard the upper aqueous solution. Add 1.9393 mg of γ-cyclodextrin and 2.0 ml of water. Using 1M NaOH, adjust the pH of the system to 10, disperse with 100 watts of ultrasound for 5 minutes, raise the temperature of the reaction system to 70° C., and keep it at this temperature for 5 hours. After the reaction is finished, the superparamagnetic gamma-cyclodextrin composite particles are obtained by known methods such as magnetic separation, centrifugation or dialysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com