Method for preparing hollow carbon ball

A carbon sphere and hollow technology is applied in the field of preparation of hollow carbon spheres to achieve the effects of high purity, short reaction time and simple post-processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Weigh 0.2g of glucose and 0.1g of ammonium sulfate, dissolve them in 35ml of deionized water, mix well and add them to a 50ml stainless steel reaction kettle.

[0029] 2. Put the above-mentioned stainless steel reaction kettle into a heating furnace with a temperature-programming function, set the heating rate at 1°C / min, after rising to 150°C, keep the temperature constant for 3 hours, and then stop heating, so that the reaction kettle is naturally in the furnace Cool to room temperature.

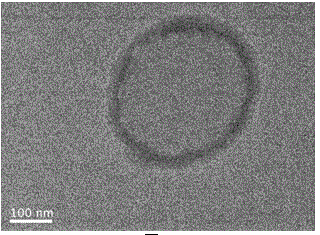

[0030] 3. Suction filter the above reaction solution, wash the product with deionized water, and finally dry the product at 60°C for 4 hours to obtain the hollow carbon sphere product. figure 1 For the TEM picture of the hollow carbon sphere that embodiment 1 makes

Embodiment 2

[0032] 1. Weigh 1g of glucose and 0.5g of ammonium sulfate, dissolve them in 35ml of deionized water, mix well and add them to a 50ml stainless steel reaction kettle.

[0033] 2. Put the above-mentioned stainless steel reaction kettle into a heating furnace with a temperature-programmed function, set the heating rate at 2°C / min, after rising to 180°C, keep the temperature constant for 2 hours, and then stop heating, so that the reaction kettle can be naturally heated in the furnace. Cool to room temperature.

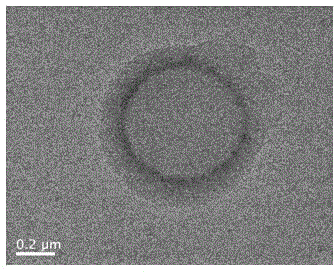

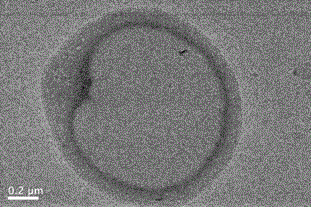

[0034] 3. Suction filter the above reaction solution, wash the product with deionized water, and finally dry the product at 60°C for 4 hours to obtain the hollow carbon sphere product. figure 2 It is the TEM figure of the hollow carbon sphere that embodiment 2 makes, image 3 It is the TEM image of the hollow carbon spheres prepared in Example 2.

Embodiment 3

[0036] 1. Weigh 5g of glucose and 0.5g of ammonium chloride and dissolve in 35ml of deionized water, mix well and add to a 50ml stainless steel reaction kettle.

[0037] 2. Put the above-mentioned stainless steel reaction kettle into a heating furnace with a temperature-programming function, set the heating rate at 1°C / min, after rising to 150°C, keep the temperature constant for 3 hours, and then stop heating, so that the reaction kettle is naturally in the furnace Cool to room temperature.

[0038] 3. Suction filter the above reaction solution, wash the product with deionized water, and finally dry the product at 60°C for 4 hours to obtain the hollow carbon sphere product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com