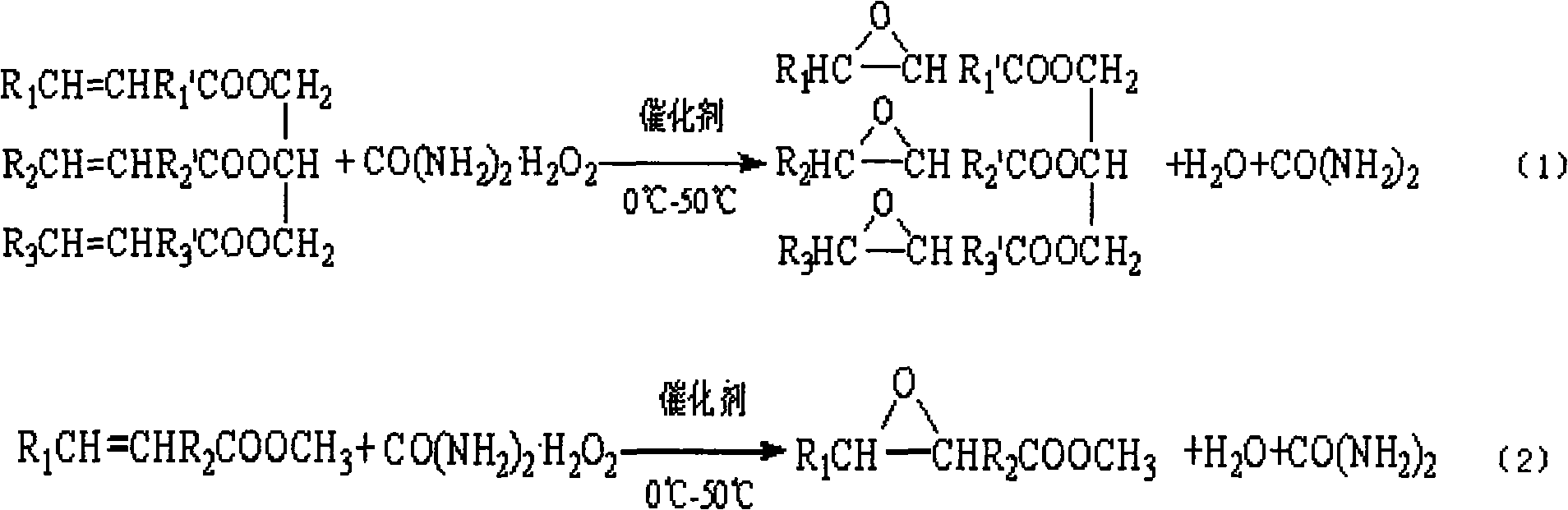

Method for preparing epoxidized soybean oil or epoxy fatty acid methyl (ethyl) ester through catalysis of organic rhenium oxide-urea peroxide

A technology of epoxidized fatty acid and epoxidized soybean oil, which is applied in organic chemistry, fatty acid production, fatty acid chemical modification, etc., can solve problems such as equipment corrosion, complicated operation, and reduced catalytic activity, and achieve low corrosiveness, simple post-treatment, The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the reactor, add a certain amount of iodine and the value is 130g I 2 / 100g of soybean oil with an acid value less than 0.5mg KOH / g, add a rhenic acid catalyst according to 0.1% of the weight of the raw soybean oil, stir vigorously and keep the temperature at 40°C, slowly add the Carbamide peroxide; the reaction stopped after 8h. After resting, the water layer was separated, and the oil layer was distilled under reduced pressure, and the temperature was controlled below 110°C. The epoxy value of the epoxidized soybean oil was 7.1%, and the conversion rate was greater than 99%.

Embodiment 2

[0024] In the reactor, add a certain amount of iodine and the value is 145g I 2 / 100g of soybean oil with an acid value less than 0.5mg KOH / g, add methyl rhenium trioxide catalyst according to 0.3% of the weight of the raw soybean oil, stir vigorously and keep the temperature at 20°C, slowly add and the weight ratio of the raw soybean oil is 1 : 0.6 carbamide peroxide; stop after 4 hours of reaction. After resting, the water layer is separated, the oil layer is distilled under reduced pressure, the temperature is controlled below 110° C., the epoxy value of the epoxidized soybean oil is 7.8%, and the conversion rate is greater than 99%.

Embodiment 3

[0026] In the reactor, add a certain amount of iodine and the value is 108gI 2 / 100g fatty acid methyl ester with an acid value less than 2mg KOH / g, add benzyl rhenium trioxide catalyst according to 0.2% of the weight of the raw material fatty acid methyl ester, stir vigorously and keep the temperature at 20°C, slowly add the weight of the raw material fatty acid methyl ester The ratio of carbamide peroxide is 1:1; the reaction stops after 6h. After resting, the water layer was separated, the oil layer was distilled under reduced pressure, the temperature was controlled below 110°C, the epoxy value of the epoxy fatty acid methyl ester was 6.16%, and the conversion rate was greater than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com