Mn element and Zn element-doped super-paramagnetic ferrite nanoparticles and preparation method thereof

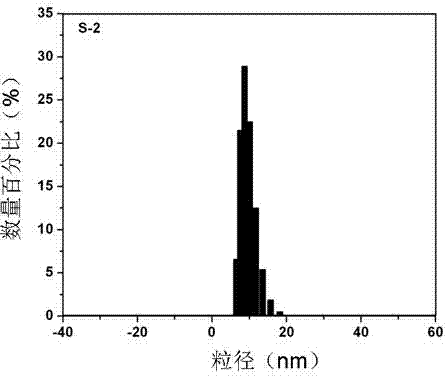

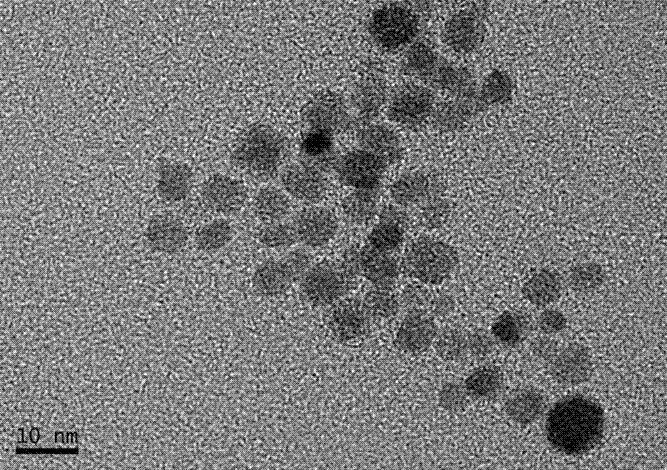

A superparamagnetic, elemental technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of large particle size, difficult to precisely control, high equipment and operation requirements, and achieve crystallinity. The effect of high, uniform size and high saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

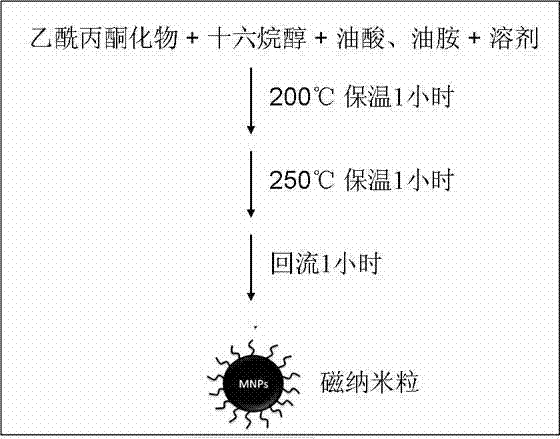

[0031] The processing steps of the present embodiment are as follows:

[0032] (1) Synthesis of magnetic nanoparticles

[0033] Two precursors of iron acetylacetonate (1 mmol) and manganese acetylacetonate (0.4 mmol) were mixed with 5 mmol of 1,2-hexadecanol, and 3 mmol of oleic acid and 3 mmol of oleylamine were added as surfactants to 25 ml of benzyl ether was used as a solvent, heated to 200°C at a speed of 3°C / min and kept for 2h, and then heated to reflux temperature at the same heating rate, and kept at about 280°C for 1h.

[0034] (2) Post-processing of magnetic nanoparticles

[0035]Cool to room temperature, precipitate in 250 ml ethanol, decant the supernatant, and centrifuge at low speed (3500 rpm, 5 min). Add the obtained black precipitate to oleic acid (0.15 mmol) and oleylamine (0.15 mmol) to disperse in n-hexane and centrifuge at high speed (8000 rpm, 10 min), then precipitate the solution in ethanol again, then centrifuge at low speed to remove excess solvent,...

Embodiment 2

[0038] The processing steps of the present embodiment are as follows:

[0039] (1) Synthesis of magnetic nanoparticles

[0040] Two precursors of iron acetylacetonate (1 mmol) and manganese acetylacetonate (1.25 mmol) were mixed with 5 mmol of 1,2-hexadecanol, and 3 mmol of oleic acid and 3 mmol of oleylamine were added as surfactants to 25 ml of benzyl ether was used as a solvent, heated to 200°C at a speed of 3°C / min and kept for 2h, and then heated to reflux temperature at the same heating rate, and kept at about 280°C for 1h.

[0041] (2) Post-processing of magnetic nanoparticles

[0042] Cool to room temperature, precipitate in 250 ml ethanol, decant the supernatant, and centrifuge at low speed (3500 rpm, 5 min). Add the obtained black precipitate to oleic acid (0.15 mmol) and oleylamine (0.15 mmol) to disperse in n-hexane and centrifuge at high speed (8000 rpm, 10 min), then precipitate the solution in ethanol again, then centrifuge at low speed to remove excess solven...

Embodiment 3

[0045] The processing steps of the present embodiment are as follows:

[0046] (1) Synthesis of magnetic nanoparticles

[0047] Three precursors of iron acetylacetonate (0.75 mmol), manganese acetylacetonate (0.35 mmol) and zinc acetylacetonate (0.15 mmol) were mixed with 5 mmol 1,2-hexadecanol, 3 mmol oleic acid, 3 mmol Oleylamine was used as a surfactant, and 25 ml benzyl ether was used as a solvent, heated to 200°C at a rate of 3°C / min and kept for 2 hours, and then heated to reflux temperature at the same heating rate, and kept at about 280°C for 1 hour.

[0048] (2) Post-processing of magnetic nanoparticles

[0049] Cool to room temperature, precipitate in 250 ml ethanol, decant the supernatant, and centrifuge at low speed (3500 rpm, 5 min). Add the obtained black precipitate to oleic acid (0.15 mmol) and oleylamine (0.15 mmol) to disperse in n-hexane and centrifuge at high speed (8000 rpm, 10 min), then precipitate the solution in ethanol again, then centrifuge at low ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com