Preparation method of FeCo alloy absorbing material

A technology of wave-absorbing materials and alloys, applied in the field of magnetic wave-absorbing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

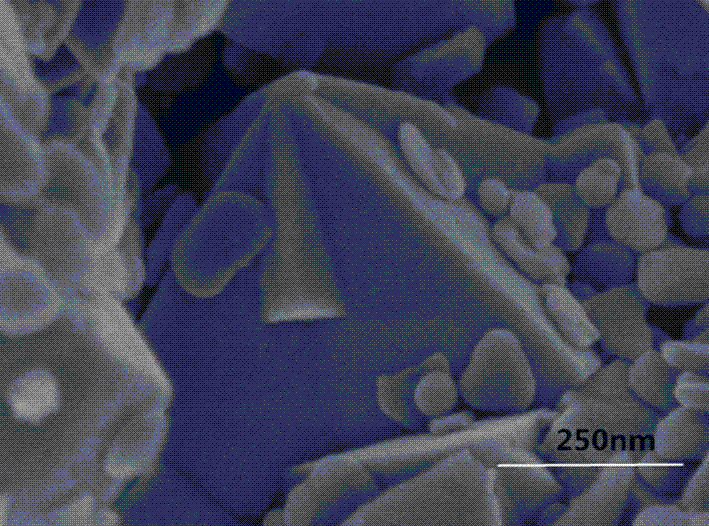

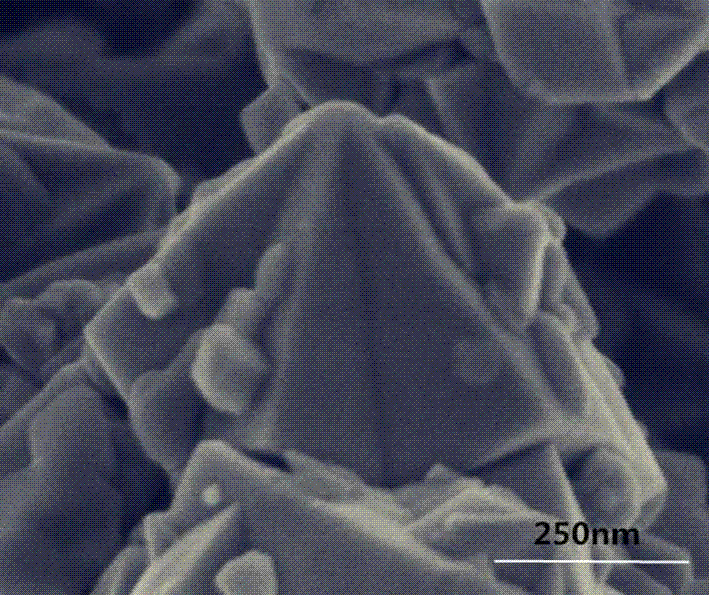

Image

Examples

Embodiment 1

[0032] A preparation method of FeCo alloy wave-absorbing material, comprising the steps of:

[0033] Step 1, weigh 8 g of ferrous sulfate and 8 g of cobalt chloride respectively and place them in a three-necked flask, add 100 mL of distilled water to the flask to obtain the initial solution, and magnetically stir the solution for 5 minutes;

[0034] Step 2, under a nitrogen protection environment, 5 g of sodium hydroxide is added to the solution treated in step 1, and at the same time, 50 mL of hydrazine hydrate is quickly added to the solution, wherein the mass percentage of hydrazine hydrate is 85%;

[0035] In step 3, the solution treated in step 2 is subjected to ultrasonic treatment, the time of ultrasonic treatment is 1 h, and the temperature of ultrasonic treatment is 70°C;

[0036] Step 4: Cool the ultrasonically treated solution to room temperature, wash with distilled water and absolute ethanol three times respectively, and then dry to obtain the desired product. The...

Embodiment 2

[0038] A preparation method of FeCo alloy wave-absorbing material, comprising the steps of:

[0039] Step 1, weigh 9 g of ferrous sulfate and 9 g of cobalt chloride respectively and place them in a three-necked flask, add 100 mL of distilled water to the flask to obtain an initial solution, and magnetically stir the solution for 5 minutes;

[0040] Step 2, under a nitrogen protection environment, add 6 g of sodium hydroxide to the solution treated in step 1, and then quickly add 40 mL of hydrazine hydrate to the solution, wherein the mass percentage of hydrazine hydrate is 85%;

[0041] In step 3, the solution treated in step 2 is subjected to ultrasonic treatment, the time of ultrasonic treatment is 2 h, and the temperature of ultrasonic treatment is 50°C;

[0042] Step 4: Cool the ultrasonically treated solution to room temperature, wash with distilled water and absolute ethanol three times respectively, and then dry to obtain the desired product. The obtained product has th...

Embodiment 3

[0044] A preparation method of FeCo alloy wave-absorbing material, comprising the steps of:

[0045] Step 1, weigh 10 g of ferrous sulfate and 10 g of cobalt chloride respectively and place them in a three-necked flask, add 100 mL of distilled water to the flask to obtain an initial solution, and magnetically stir the solution for 5 minutes;

[0046] Step 2, under a nitrogen protection environment, add 6 g of sodium hydroxide to the solution treated in step 1, and then quickly add 45 mL of hydrazine hydrate to the solution, wherein the mass percentage of hydrazine hydrate is 85%;

[0047] In step 3, the solution treated in step 2 is subjected to ultrasonic treatment, the time of ultrasonic treatment is 3 h, and the temperature of ultrasonic treatment is 30°C;

[0048] Step 4: Cool the ultrasonically treated solution to room temperature, wash with distilled water and absolute ethanol three times respectively, and then dry to obtain the desired product. The obtained product has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com