High saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material and preparation method thereof

A technology of iron-based nanocrystals and soft magnetic alloys, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of complex preparation process, low saturation magnetization, large high-frequency loss, etc., to reduce costs and improve saturation. Magnetization, the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw materials such as iron (3N5), silicon (4N), boron (3N), phosphorus iron (3N) and copper (3N) are used according to the alloy composition Fe 82.7 Si 3.95 B 8.4 P 4.3 Cu 0.65 (atomic percentage) proportioning; then put the good proportioning raw materials into the ceramic crucible of the induction melting furnace, and high-frequency induction melting 4 times to obtain an alloy ingot with uniform composition;

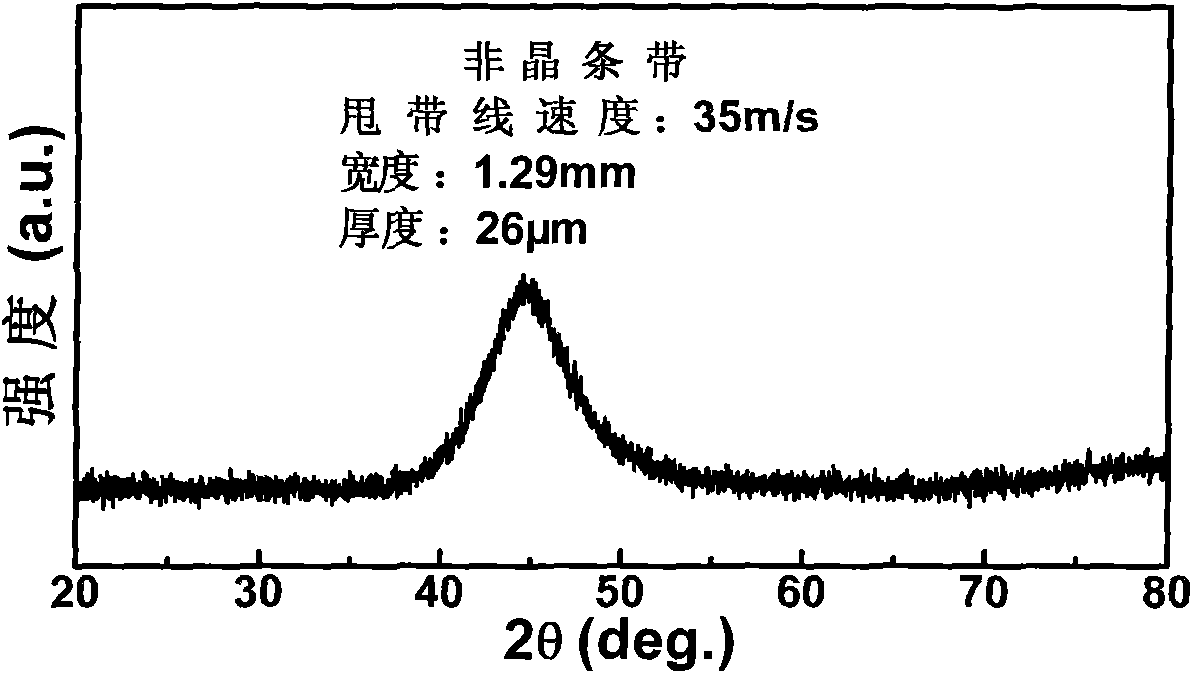

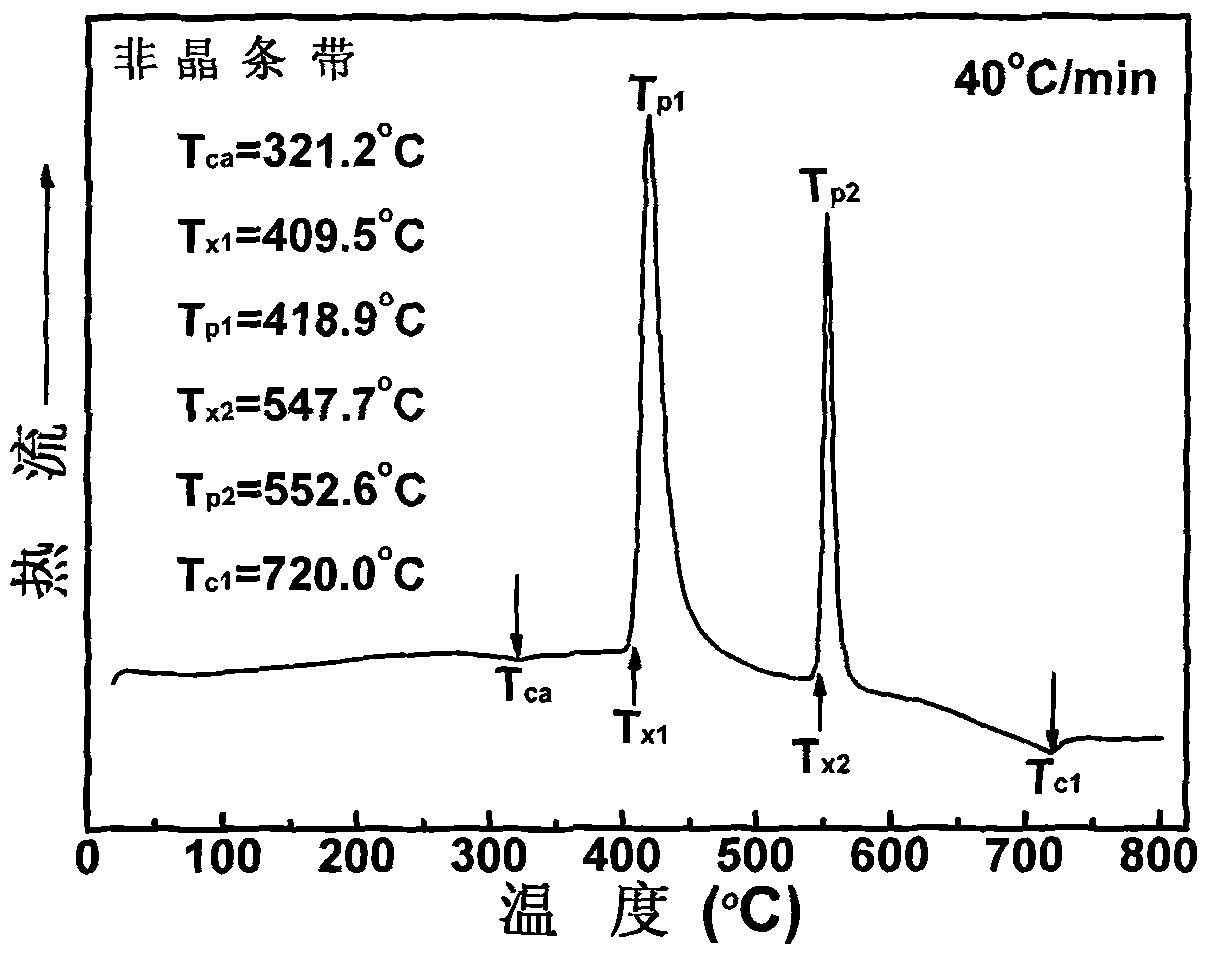

[0031] The alloy ingot is crushed and loaded into a quartz tube, and the single-roller quenching strip process is adopted, and the strip is thrown at a speed of 35m / s in an Ar atmosphere to obtain an amorphous alloy strip with a width of 1.29mm and a thickness of 26μm;

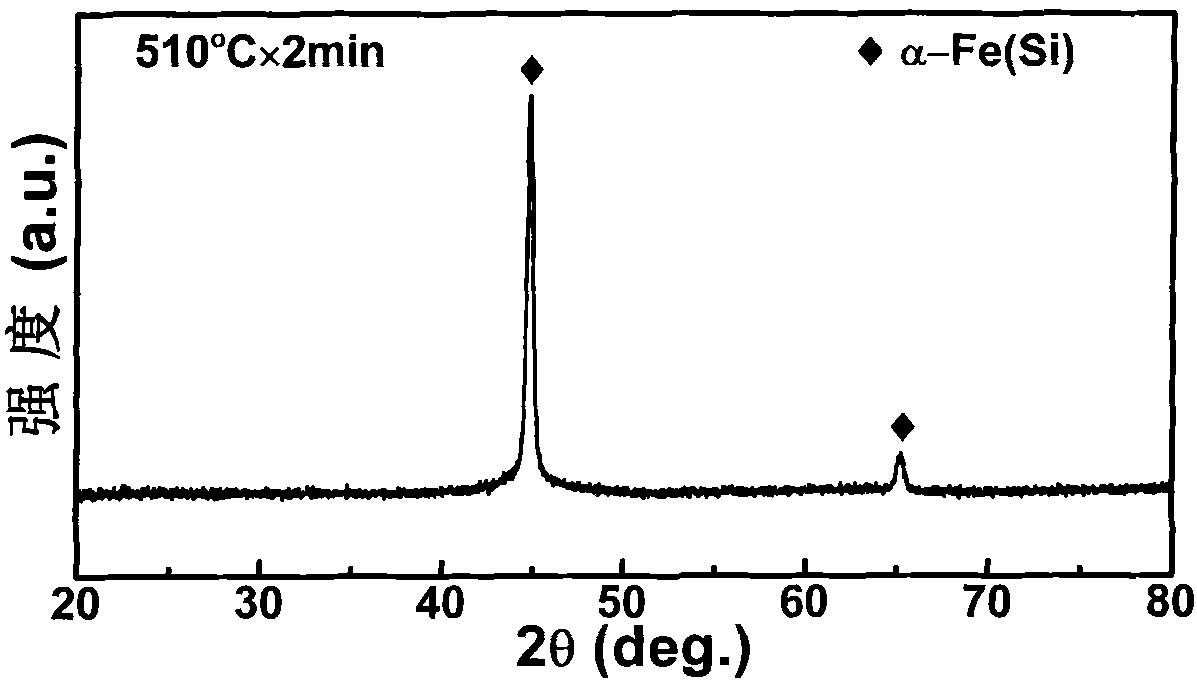

[0032] Place the amorphous strips in a quartz tube and evacuate to 3 × 10 -3 Pa, filled with Ar gas to an atmospheric pressure, then closed the quartz tube; placed the quartz tube in a heat treatment furnace, raised the temperature to 510 °C at a rate of 2.2 °C / s, kept the temperature for 2 ...

Embodiment 2

[0038] Raw materials such as iron (3N5), silicon (4N), boron (3N), phosphorus iron (3N) and copper (3N) are used according to the alloy composition Fe 82.7 Si 3.95 B 8.4 P 4.3 Cu 0.65 (atomic percentage) proportioning; Synthesize the amorphous strip with the technique in embodiment 1, seal in the quartz tube and place in the heat treatment furnace, rise to 515 ℃ with the heating rate of 2.2 ℃ / second then, keep warm for 1.25 minutes, immediately The quartz tube was taken out and quenched in water to room temperature.

[0039] The XRD patterns of the nanocrystalline strips after the crystallization heat treatment at 515°C for 1.25 minutes are as follows: Figure 5 shown. It can be seen that the nanocrystals precipitated by primary crystallization are body-centered cubic Fe with Si in solid solution, that is, α-Fe(Si). However, the grain size is very small, and the Rietveld structure refinement can be calculated by using the basic parameter method of the Topas 3.0 software ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com