Method of synthesizing low-oxygen superfine cobalt powder

A technology of ultra-fine cobalt powder and synthesis method, which is applied in the field of cobalt powder preparation, can solve problems such as difficulty in controlling the particle size growth of cobalt powder, high oxygen content, and uneven particle size of cobalt powder, so as to solve the phenomenon of ignition and reduce oxygen The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

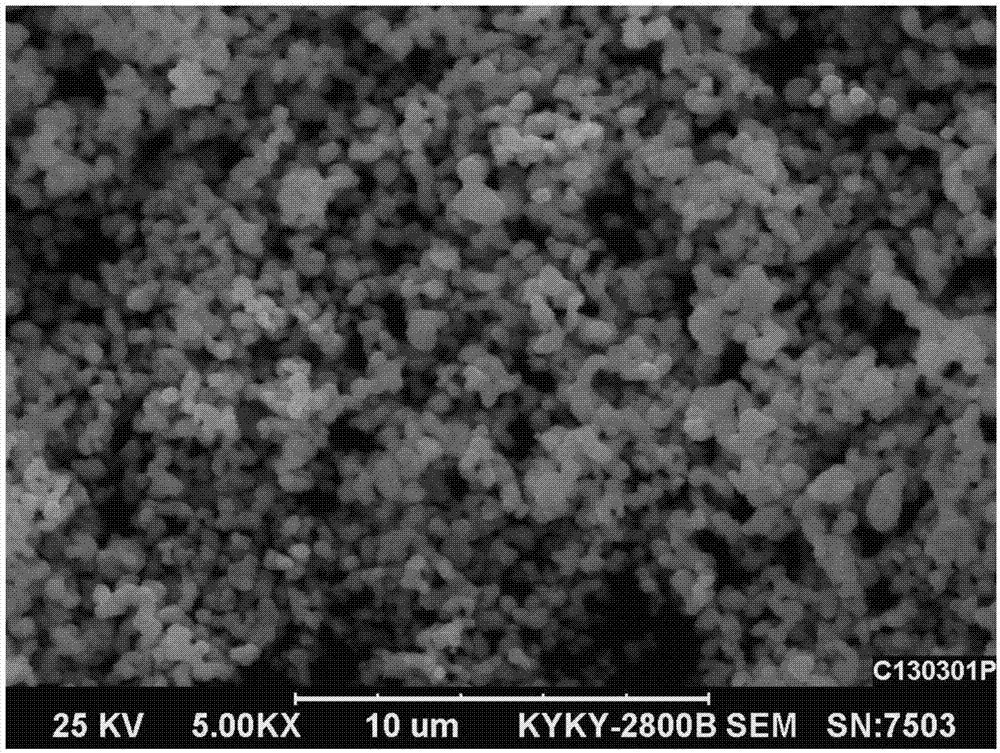

[0025] The cobalt chloride solution of 110g / l and the ammonium bicarbonate solution of 250g / l are added in the reaction kettle according to the cobalt chloride solution flow rate of 60L / h, and the ammonium bicarbonate flow rate of 90L / h, and the reaction pH value is controlled by adjusting the ammonium bicarbonate flow rate at 6.5 The reaction temperature is 25°C, the stirring speed is adjusted to 200r / min, and after 2 hours of feeding reaction, the feeding of cobalt chloride is stopped, and the ammonium bicarbonate is reduced to 20L / h to continue the reaction. At the same time, the temperature is slowly raised to 50°C, and the reaction is stopped after the pH value reaches 7.1. Ammonium bicarbonate was added. The synthesized precursor is washed, dried, crushed (dried at 100-200°C, jet crushed), hydrogen reduced at 300°C for 20 hours, cooled under nitrogen, crushed, mixed, sieved, and packaged. The specific indicators of the obtained cobalt powder are as follows: Fsss particle...

Embodiment 2

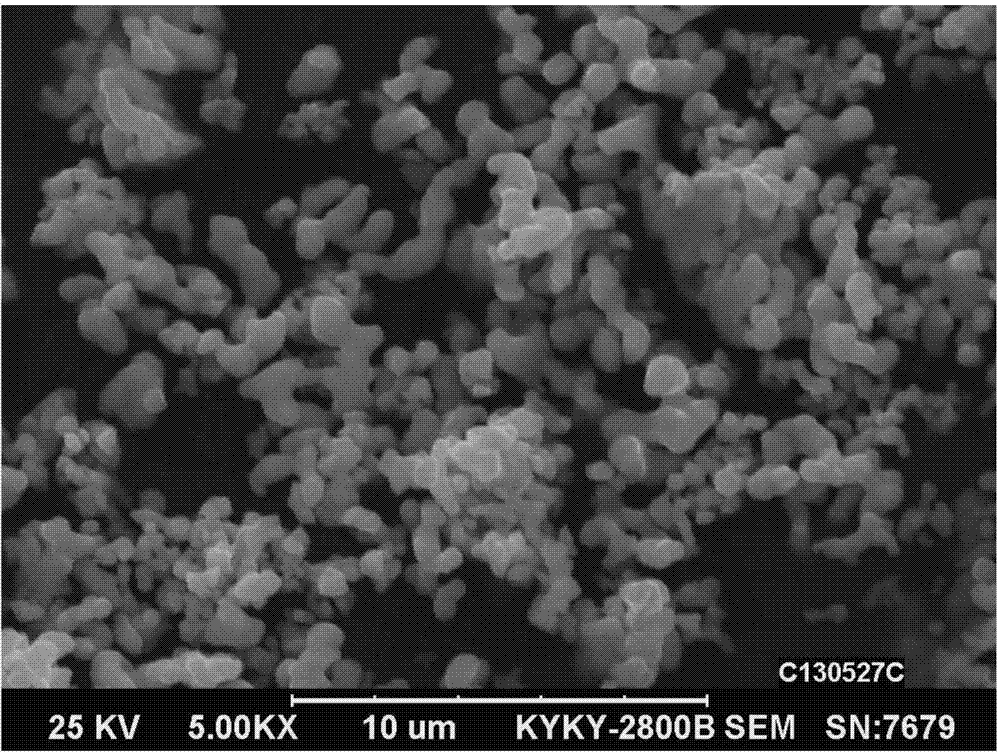

[0027] 80g / l cobalt chloride solution and 150l / h ammonium bicarbonate solution are added to the reactor according to the cobalt chloride solution flow rate of 200L / h, and the ammonium bicarbonate flow rate is about 320L / h, and the reaction pH value is controlled by adjusting the ammonium bicarbonate flow rate In 6.8, the reaction temperature is 10°C, the stirring speed is adjusted to 300r / min, and after the feeding reaction for 6 hours, the feeding of cobalt chloride is stopped, and the ammonium bicarbonate is reduced to 50l / h to continue the reaction, and at the same time, the temperature is slowly raised to 55°C, and the pH value reaches 7.3. Ammonium bicarbonate addition was stopped. The synthesized precursor is washed, dried, crushed (dried at 100-200°C, jet crushed), hydrogen reduced at 350°C*10h, and the cobalt powder obtained by reduction is cooled, crushed, mixed, sieved, and packaged under carbon dioxide.

[0028] The specific indicators of the obtained cobalt powder ...

Embodiment 3

[0030] The synthetic method of hypoxic superfine cobalt powder, step is as follows:

[0031] (1) Add 60g / l cobalt chloride solution and 100g / l ammonium bicarbonate solution into the reactor at a flow rate of 200L / h for cobalt chloride solution and 350L / h for ammonium bicarbonate, and control the reaction by adjusting the flow rate of ammonium bicarbonate PH value is 6.7~6.8;

[0032] (2) Control the reaction temperature to 40°C and the stirring speed to 150r / min. After 1 hour of reaction, stop feeding cobalt chloride, reduce ammonium bicarbonate to 60L / h and continue the reaction, while slowly raising the temperature to 50°C, and stop when the pH value reaches 7.1 Ammonium bicarbonate is added to synthesize a precursor;

[0033] (3) The synthesized precursors were washed, dried, crushed, hydrogen-reduced at 250°C for 25 hours, cooled in nitrogen, crushed, mixed, sieved, and packaged.

[0034] Cobalt powder index: Fsss particle size 0.8um, oxygen content 0.39%, average partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com