Die forging method of high-temperature alloy

A high-temperature alloy and deformed high-temperature alloy technology, which is applied in metal processing equipment, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of slow temperature rise of die forging blanks, low die life, and difficult manufacturing, etc. problem, achieve the effect of reducing heating time, reducing cost, and good heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1: Die forging cylinder-shaped die forgings for key components of a high-tech power plant.

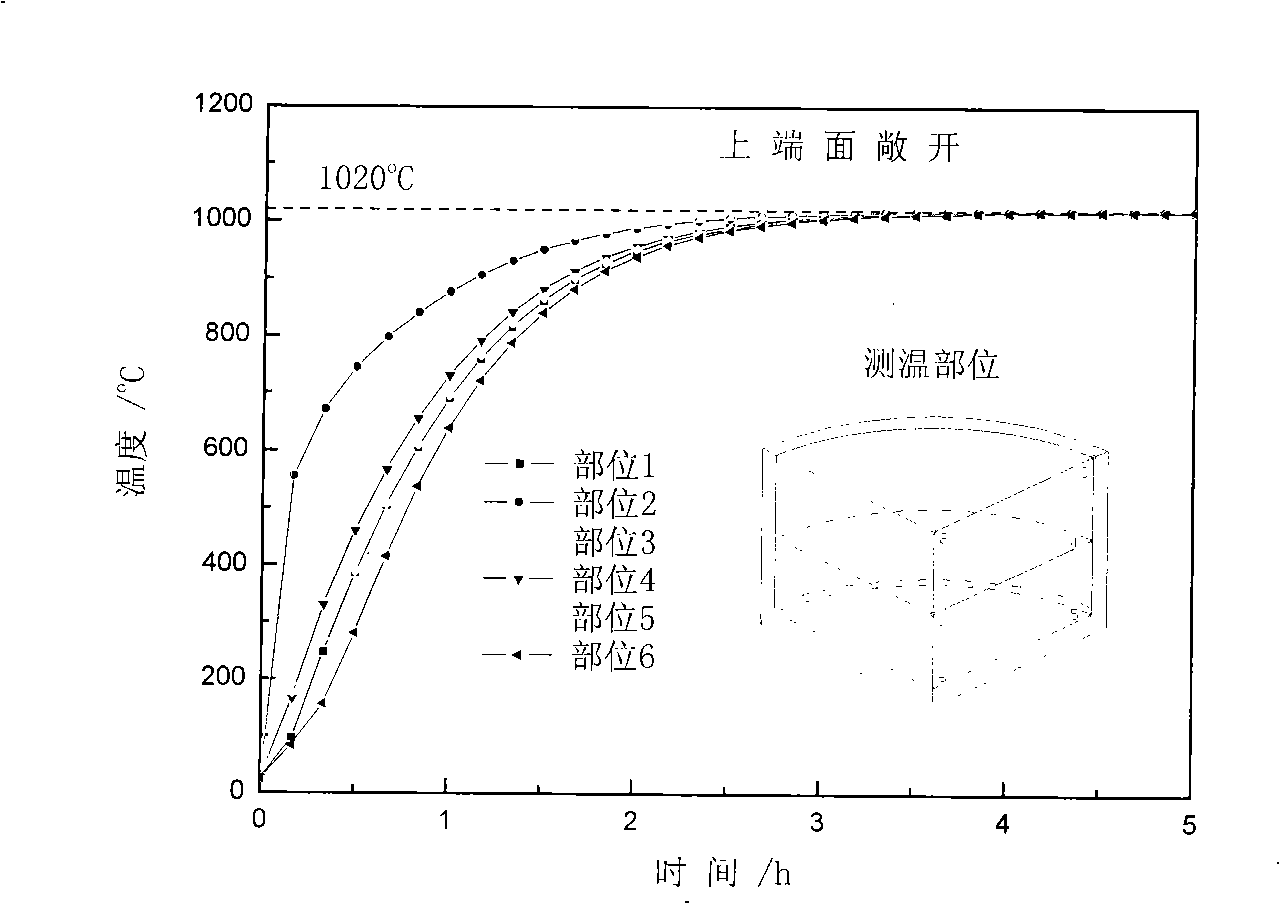

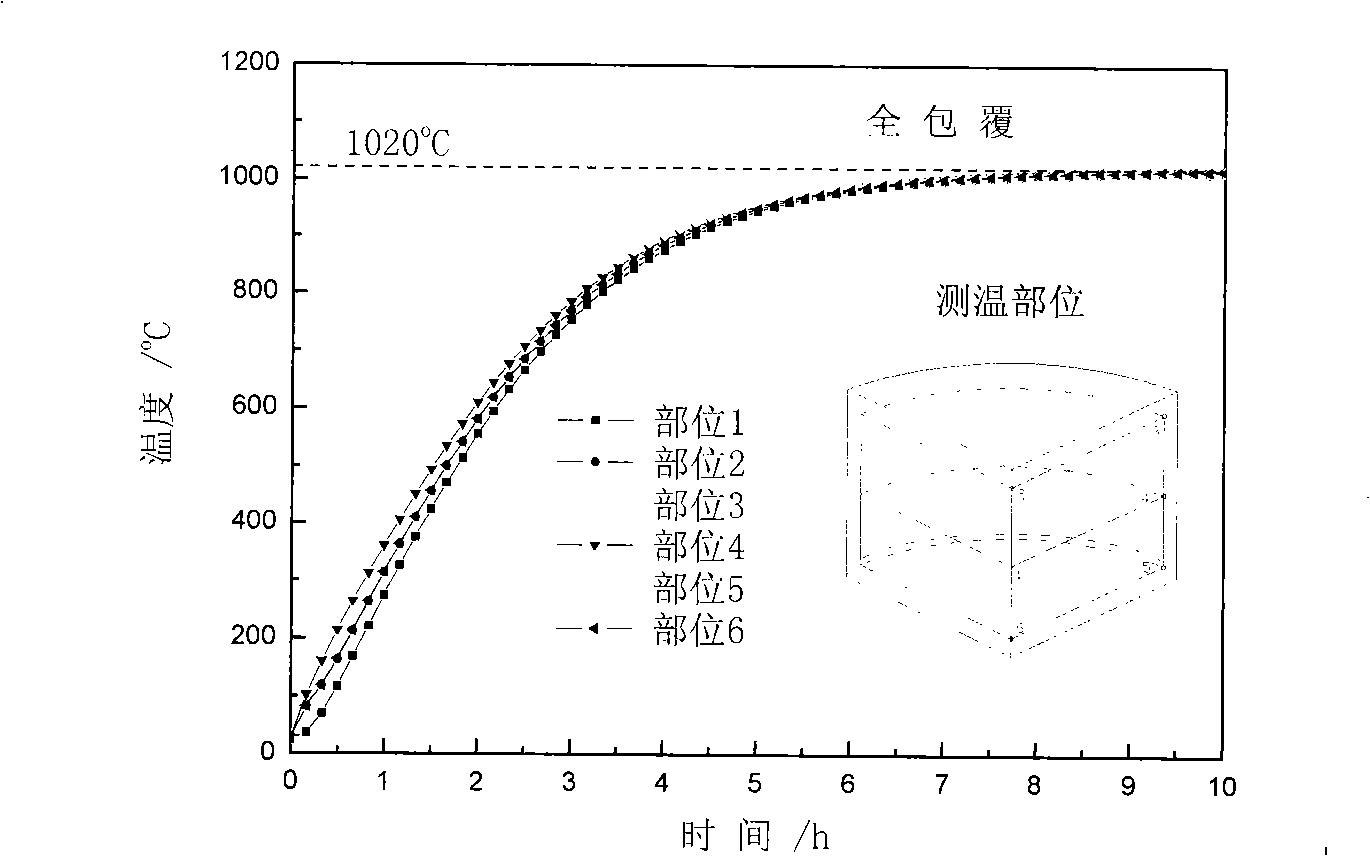

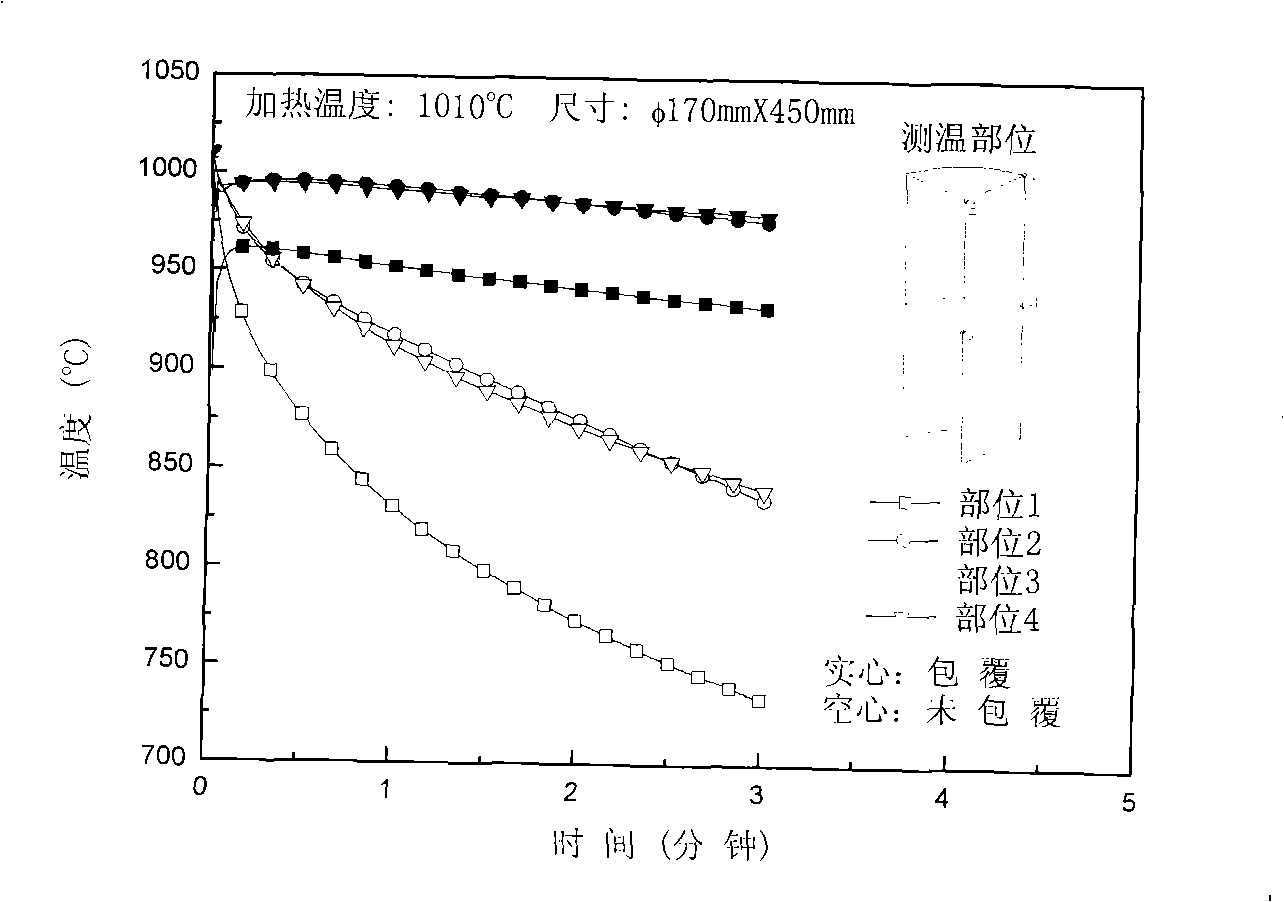

[0064] The grain size of the die forging billet is 7-8 grades, the δ phase is spherical, and a small amount of short rods. The shape of the die forging billet is a round cake. At room temperature, use a high-viscosity high-temperature adhesive to paste the pasteable heat-insulating cotton on the lower end surface and circumference of the die forging billet, open one end face, put it into a resistance heating furnace, and open one end face upwards. , the heating temperature is 900-1200°C, and the furnace temperature is 990°C when entering the furnace at high temperature. After the die forging billet is warm, the open side is covered with insulation cotton and transferred to a hydraulic press for die forging. The heating temperature of the die is 600-650°C. During the die forging process, the mold continues to be heated to keep the mold temperature constant. When molding...

Embodiment 2

[0066] Example 2: die forging a GH4169 alloy rotor forging with dual structures and dual properties.

[0067] Except that the heating temperature of the die forging billet is 1020°C, other process requirements are the same as in Example 1. The die forging has no obvious cold die structure, and has two good microstructure states: one is grade 8 fine-grained and δ-phase spheroidized structure, and the other is One is 4-5 fine-grained and δ-phase spheroidized structure, so that another high-end material product with very strict technical requirements has been successfully developed for the first time in China by applying the technology of the present invention.

Embodiment 3

[0068] Example 3: Popularization and application in die forging of difficult-to-deform superalloys

[0069] Die forged GH742, GH105, Udimet720 and other difficult-to-deform superalloys. The method for pasting the heat-insulating cotton is the same as in Example 1. The heating temperature of die forging billet is 1130~1160℃, and the final forging temperature of die forging is ≥1050℃. K3 cast superalloy is used to make the mold, the mold heating temperature is 800℃~900℃, the molding speed is 2mm / s, the surface condition after die forging is good, the alloy structure and performance can meet the requirements of technical conditions, and the difficult-to-deform alloy die forging technology has been realized breakthrough. The difference between the die forging process and the fine-grained GH4169 alloy die forging process is that because this type of superalloy must have a high final forging temperature in order to fully avoid cracks in the die forging, the heating temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com