Electrical heating type cylindrical raw coal spontaneous combustion testing device and method

A technology of electric heating and test equipment, which is applied in the direction of material weighing, instruments, measuring devices, etc., can solve the problem that the stacking and management of coal yards in power plants do not have test reference value, and cannot truly reflect the spontaneous combustion of coal piles in power plants, test status and The actual spontaneous combustion state of the coal pile in the power plant is very different, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

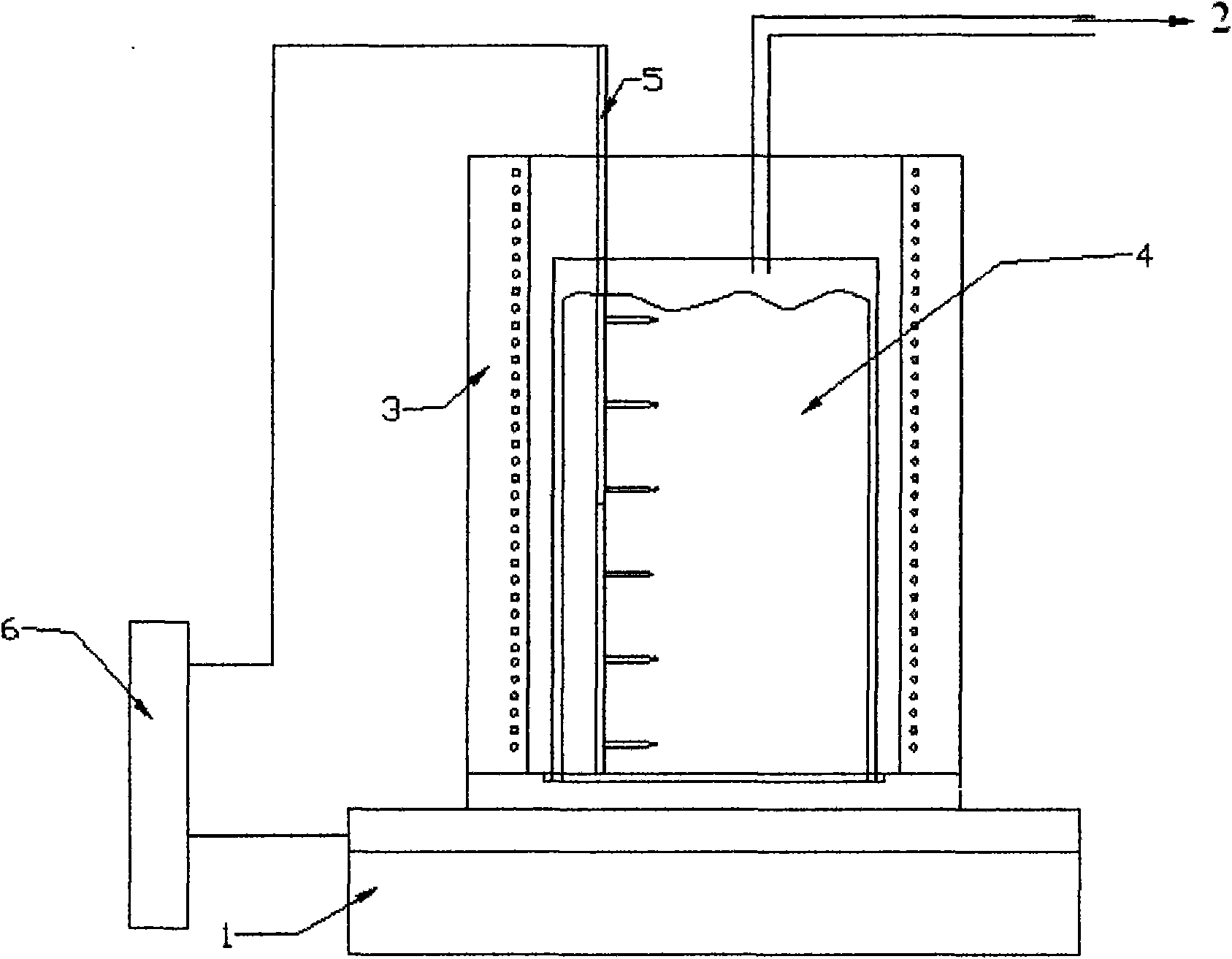

[0047] In the first step, the raw coal of Zhalainuoer lignite is crushed to a particle size below 13mm, and put into the cylindrical electric heating furnace 3, leaving a height of 5mm on the top of the cylindrical electric heating furnace 3,

[0048] In the second step, the heating condition is controlled as 30°C-60min-60°C-90min-150°C-150min-300°C-10min-300°C-50min-30°C,

[0049] The third step: install the pipeline 2 of the oxygen meter on the gas outlet pipe of the furnace cover of the cylindrical electric heating furnace 3,

[0050] Step 4: Weigh Zhalai Nuoer lignite sample 4, the initial weight is 11.38kg,

[0051] The fifth step is to raise the temperature of the cylindrical electric heating furnace 3 through the temperature controller, thereby heating the internal sample 4, and collecting the six-level temperature of the coal pile 4, which are 1 to 6 from top to bottom, At the same time, the weight of sample 4 is also measured, and the oxygen content is manually recor...

example 2

[0057] In the first step, the live chicken and rabbit raw coal sample 4 is crushed to a particle size below 13 mm, and put into the cylindrical electric heating furnace 3, leaving a height of 6 mm on the top of the cylindrical electric heating furnace 3,

[0058] In the second step, the heating condition is controlled as 30°C-60min-60°C-90min-150°C-150min-300°C-10min-300°C-50min-30°C,

[0059] Step 3: Install the pipeline 2 of the deaeration meter on the gas outlet pipe of the furnace cover of the cylindrical electric heating furnace 3

[0060] Step 4: Weigh live chicken and rabbit coal sample 4, the initial weight is 11.96kg,

[0061] The fifth step is to raise the temperature of the cylindrical electric heating furnace 3 through the temperature controller, thereby heating the internal sample 4, and collecting the six-level temperature of the coal pile 4, which are 1 to 6 from top to bottom, At the same time, the weight of sample 4 is also measured, and the oxygen content is...

example 3

[0067] In the first step, the Baidong coal sample 4 is crushed to a particle size below 13 mm, and put into the cylindrical electric heating furnace 3, leaving a height of 4 mm on the top of the cylindrical electric heating furnace 3,

[0068] In the second step, the heating condition is controlled as 30°C-60min-60°C-90min-150°C-150min-300°C-10min-300°C-50min-30°C,

[0069] The third step: install the pipeline 2 of the oxygen meter on the gas outlet pipe of the furnace cover of the cylindrical electric heating furnace 3,

[0070] The fourth step: weigh Baidong coal sample 4, the initial weight is 12.36kg,

[0071] The fifth step is to raise the temperature of the cylindrical electric heating furnace 3 through the temperature controller, thereby heating the internal sample 4, and collecting the six-level temperature of the coal pile 4, which are 1 to 6 from top to bottom, At the same time, the weight of sample 4 is also measured, and the oxygen content is manually recorded onc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com