Magnetic iron oxide hollow microsphere particle having mesoporous structure and making method and uses thereof

A technology of magnetic iron oxide and nano-magnetic iron oxide, which is applied in the manufacture of inductors/transformers/magnets, magnetism of inorganic materials, electrical components, etc., can solve the problems of preparation and application of mesoporous magnetic hollow particles, and is easy to popularize and apply , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

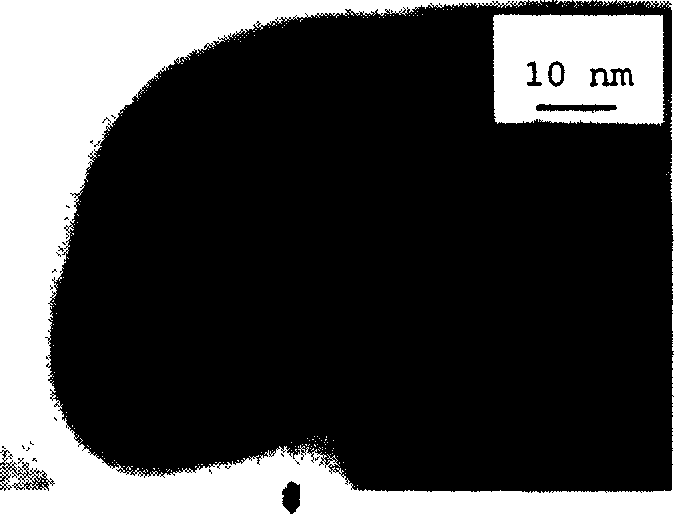

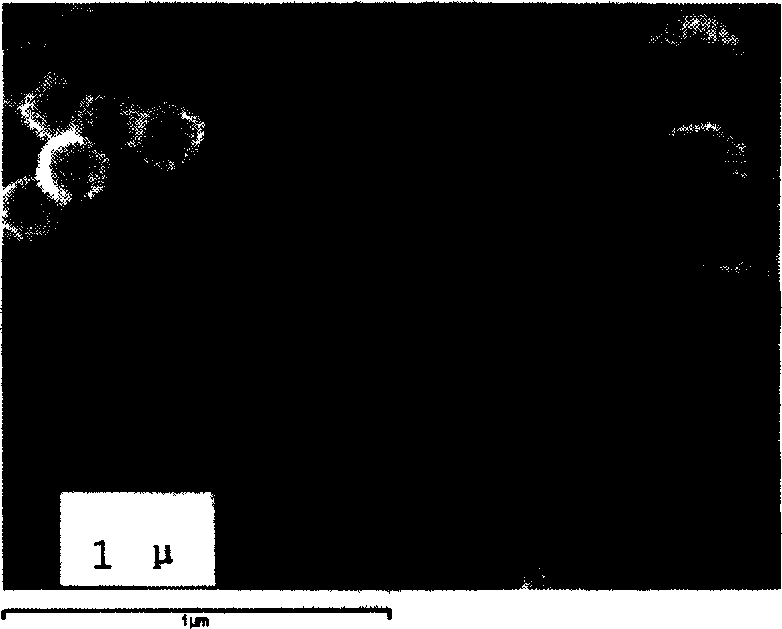

[0045] Take 80-100 ml of homemade (or commercially available) polystyrene particle (240 nm) emulsion, add 2.0 liters of double distilled water and 100-800 ml of ethylene glycol, and stir evenly. Slowly raise the temperature to 80-100°C under stirring; slowly add 10-100mmol of hexamethylenetetramine and 50-120mmol of ferric dichloride into the system for continuous reaction. Continue to react for 30 minutes after the injection. Then centrifuge and precipitate at a speed of 1000-4000 rpm; after removing the supernatant, add 2.0 liters of double-distilled water for washing, and centrifuge again, repeating this three times. Finally, it is baked at 70°C for 24 hours, and the organic microsphere composite submicron particles with a core size of 240 nanometers and magnetic iron oxide particles are obtained. Composite particles composed of iron oxide particles and a mesopore size of 3 to 7 nanometers.

Embodiment 2

[0047] Take 80-100 ml of self-made (or commercially available) polystyrene particle (320-380 nm) emulsion, add 2800 ml of double-distilled water and 150-850 ml of ethylene glycol, and stir evenly. Slowly heat up to 80°C under stirring; 10-100mmol of hexamethylenetetramine and 50-90mmol of ferric chloride solution are slowly added to the system for continuous reaction. Continue to react for 30 to 90 minutes after the injection. Then centrifuge and precipitate at a speed of 1000-2000 rpm; after removing the supernatant, add 3000 ml of double distilled water to wash, and centrifuge again, repeating this three times. Finally, bake at 70°C for 24 hours to obtain organic microsphere composite submicron particles with a core size of 320-380 nanometers, a magnetic iron oxide particle coating of 380-480 nanometers, and a shell layer with a particle size of 30-80 nanometers. Composed of magnetic iron oxide particles, composite particles with a mesopore size of 3 to 7 nanometers.

Embodiment 3

[0049] Take 80-100 ml of homemade (or commercially available) polystyrene particle (300 nanometer) emulsion, add 3.0 liters of double distilled water and 150-850 ml of ethylene glycol, and stir evenly. Slowly raise the temperature to 70-95°C under stirring; slowly add 10-100mmol hexamethylenetetramine and 60-120mmol ferric chloride into the system for continuous reaction. After the injection, put 10-50mmol of hexamethylenetetramine and 30-50mmol of ferric dichloride into the injection tube respectively, inject at a speed of 0.1-0.5ml / min, and continue to react for 30-40 minutes after injection . Then centrifuge and precipitate at a speed of 1000-3000 rpm; remove the supernatant, add 3.0 liters of double distilled water for washing, and centrifuge again. Finally, it is baked at 70°C for 24 hours, and the organic microsphere composite submicron particles with a core size of 300 nm and magnetic iron oxide particles are obtained. The particle size is 400-460 nm. Composite partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com