A kind of method for preparing coarse molybdenum powder

A molybdenum powder and powder technology, which is applied in the field of pre-compressed granulation to produce coarse molybdenum powder, can solve the problems of complex process, high production cost, and poor performance of molybdenum powder, and achieve simplified preparation process, improved strength, and reduced preparation cost. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

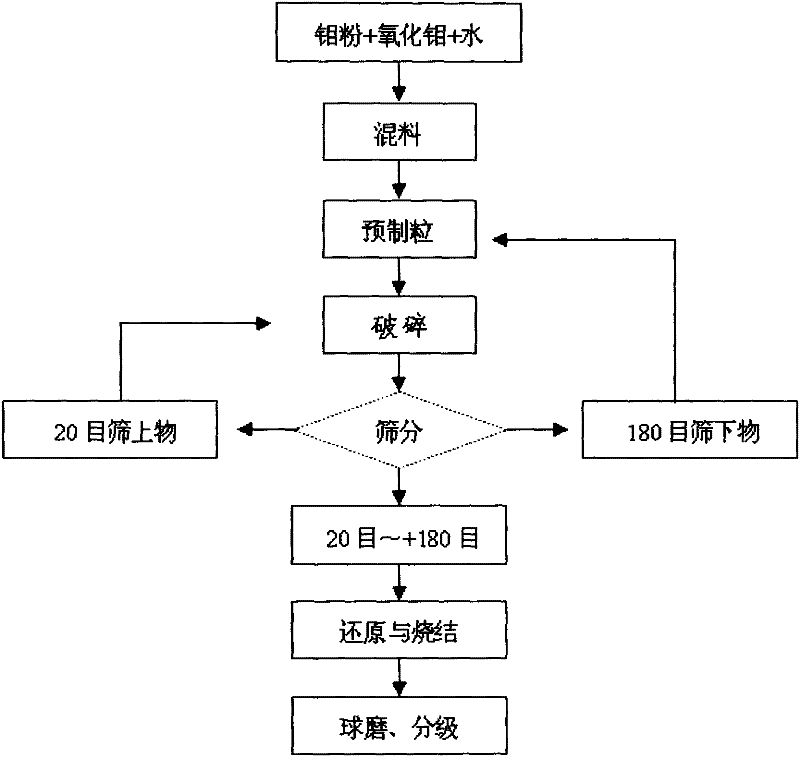

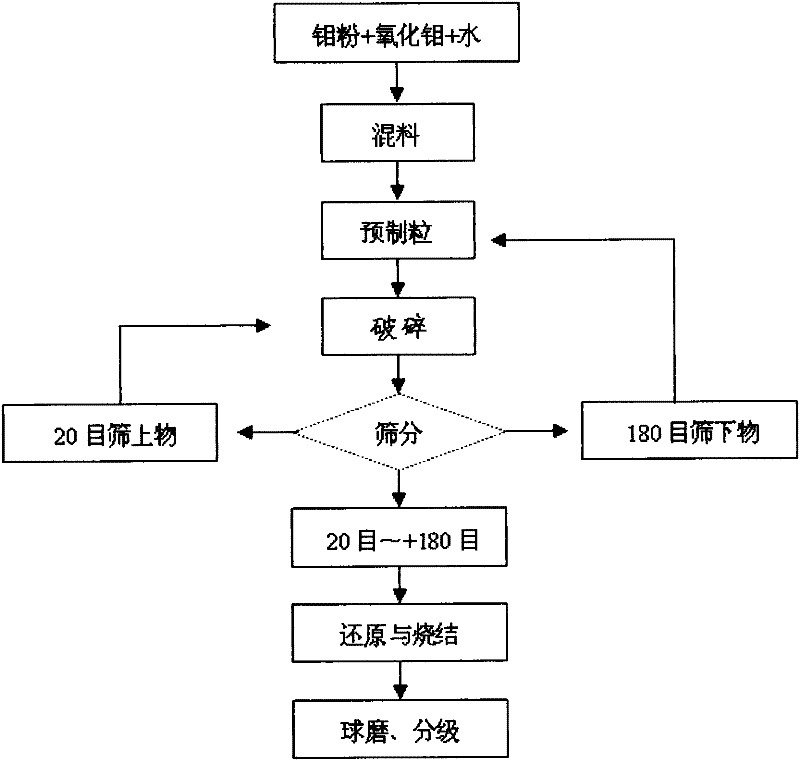

[0039] Embodiment 1: as figure 1 Shown, a kind of method for preparing coarse particle molybdenum powder comprises the steps:

[0040] A. Common molybdenum powder: MoO 3 After the powder is mixed in a weight ratio of 1.5:1, spray deionized water into the mixed powder according to the ratio of 4ml deionized water / 100g mixed powder, stir well and then mix for 60 minutes;

[0041] B, the mixture of step A is pressed into a billet by isostatic pressing, the pressure value of isostatic pressing is 100MPa, and the holding time is 100s;

[0042] C. Screen the pressed compact obtained in step B to obtain (-20 mesh, +180 mesh) prefabricated powder after crushing; after screening, return the oversize of +20 mesh to continue crushing, and return the undersize of -180 mesh to isostatic pressing suppress.

[0043] D. The prefabricated powder obtained in step C is subjected to hydrogen reduction, the reduction temperature is 750°C; the reduction time is 12h, and the hydrogen flow rate is 2...

Embodiment 2

[0045] Embodiment 2: as figure 1 Shown, a kind of method for preparing coarse particle molybdenum powder comprises the steps:

[0046] A. Combine ordinary molybdenum powder with MoO 2 After the powder is mixed at a weight ratio of 4:1, spray deionized water into the mixed powder according to the ratio of 8ml deionized water / 100g mixed powder, stir well and then mix for 30 minutes;

[0047] B, the mixture of step A is pressed into a billet by isostatic pressing, the pressure value of isostatic pressing is 100MPa, and the holding time is 114s;

[0048] C. Screen the pressed compact obtained in step B to obtain (-20 mesh, +180 mesh) prefabricated powder after crushing; after screening, return the oversize of +20 mesh to continue crushing, and return the undersize of -180 mesh to isostatic pressing suppress.

[0049] D. The prefabricated powder obtained in step C is subjected to hydrogen reduction, the reduction temperature is 970°C; the reduction time is 10h, and the hydrogen ...

Embodiment 3

[0051] Embodiment 3: a kind of method for preparing coarse particle molybdenum powder, comprises the steps:

[0052] A. Common molybdenum powder: MoO 3 After the powder is mixed in a weight ratio of 4:1, spray deionized water into the mixed powder according to the ratio of 8ml deionized water / 100g mixed powder, stir well and then mix for 30 minutes;

[0053] B, the mixture of step A is pressed into a billet by isostatic pressing, the pressure value of isostatic pressing is 100MPa, and the holding time is 114s;

[0054] C. Screen the pressed compact obtained in step B to obtain (-20 mesh, +180 mesh) prefabricated powder after crushing; after screening, return the oversize of +20 mesh to continue crushing, and return the undersize of -180 mesh to isostatic pressing suppress.

[0055] D. The prefabricated powder obtained in step C is subjected to hydrogen reduction, the reduction temperature is 970°C; the reduction time is 12h, and the hydrogen flow rate is 20L / h;

[0056] E, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com