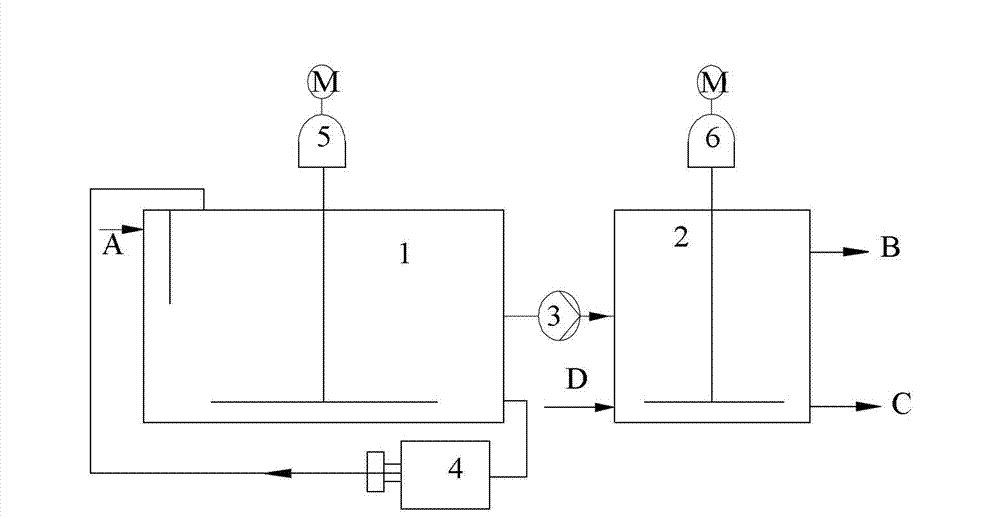

White mud/acetylene sludge slurry preparing device and process

A technology of calcium carbide slag and lime mud, applied in chemical instruments and methods, mixers, mixing methods, etc., can solve the problems of small improvement in desulfurization efficiency and gypsum quality, affecting desulfurization equipment and desulfurization effect, and limited impurity separation effect, etc. Achieve the effect of reducing investment cost and operating cost, improving gypsum quality, and improving operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

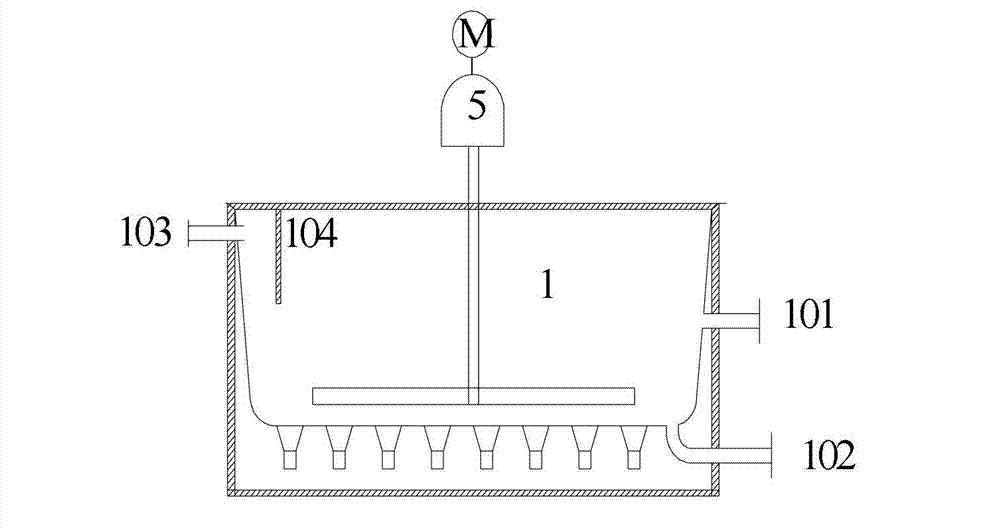

Embodiment 1

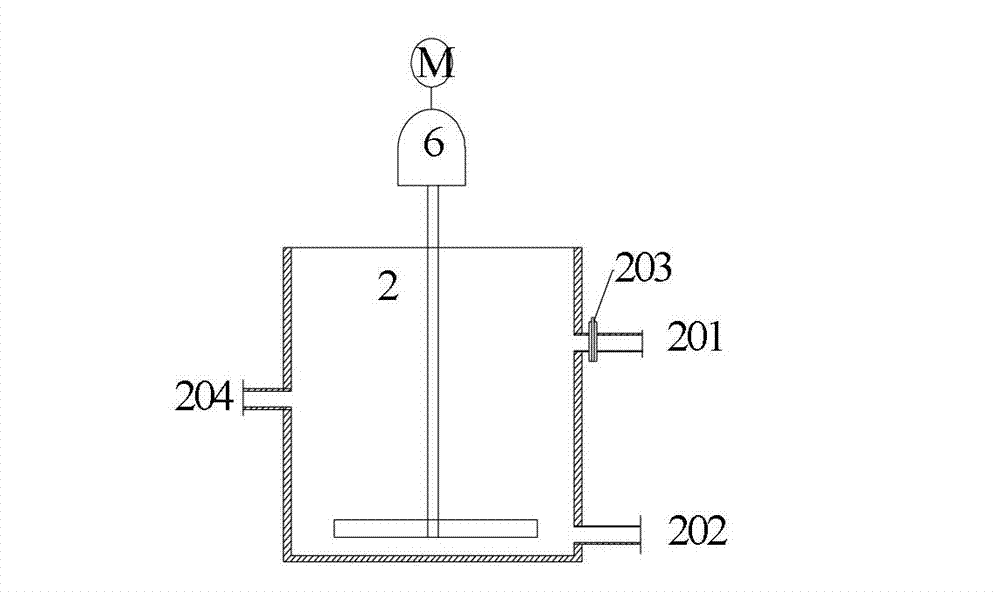

[0050] A paper mill, a 170t / h coal-fired boiler lime mud-gypsum wet flue gas desulfurization project adopts the pulping device and process of the present invention, the power of the ultrasonic cleaning machine is 5.4KW, the frequency is 40KHz, and the volume power of the built-in agitator is 50W / m 3 , the power of the homogenizer is 2.7KW, the speed is 2900rpm, and the volume power of the built-in agitator in the sedimentation separation tank is 20W / m 3 , the pore size of the microporous membrane is 10 μm, the purity of the original lime mud is 89%, and the circulation in the homogenizer is cut 6 times.

[0051] After the treatment of the present invention, the purity of white mud in the slurry C discharged from the second slurry outlet of the settling separation tank is greater than 94%, and the particle size is less than 45 μm. Use the terminal slurry of the pulping process as the desulfurization absorbent, control the pH value of the slurry to 5.2, and the liquid-gas rati...

Embodiment 2

[0053] A chemical company has two 75t / h coal-fired boilers in its own thermal power plant. The calcium carbide slag-gypsum wet flue gas desulfurization project adopts the pulping device and process of the present invention. The power of the ultrasonic cleaning machine is 5.4KW, the frequency is 40KHz, and the volume power of the built-in agitator 40W / m 3 , the power of the homogenizer is 2.7KW, the speed is 2900rpm, and the volume power of the built-in agitator in the sedimentation separation tank is 30W / m 3 , the pore size of the microporous membrane is 8 μm, the purity of the original carbide slag is 80%, and the circulation in the homogenizer is cut 4 times.

[0054] After the treatment of the present invention, the purity of white mud in the slurry C discharged from the second slurry outlet of the settling separation tank is greater than 90%, and the particle size is less than 45 μm. Use the terminal slurry of the pulping process as the desulfurization absorbent, control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com