Method for preparing high-purity cobalt

A high-purity, solution technology, applied in photography technology, instruments, photography auxiliary technology and other directions, can solve the problems of easy pollution, high production cost, unsatisfactory solution depth purification, etc., to reduce costs and prevent process pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

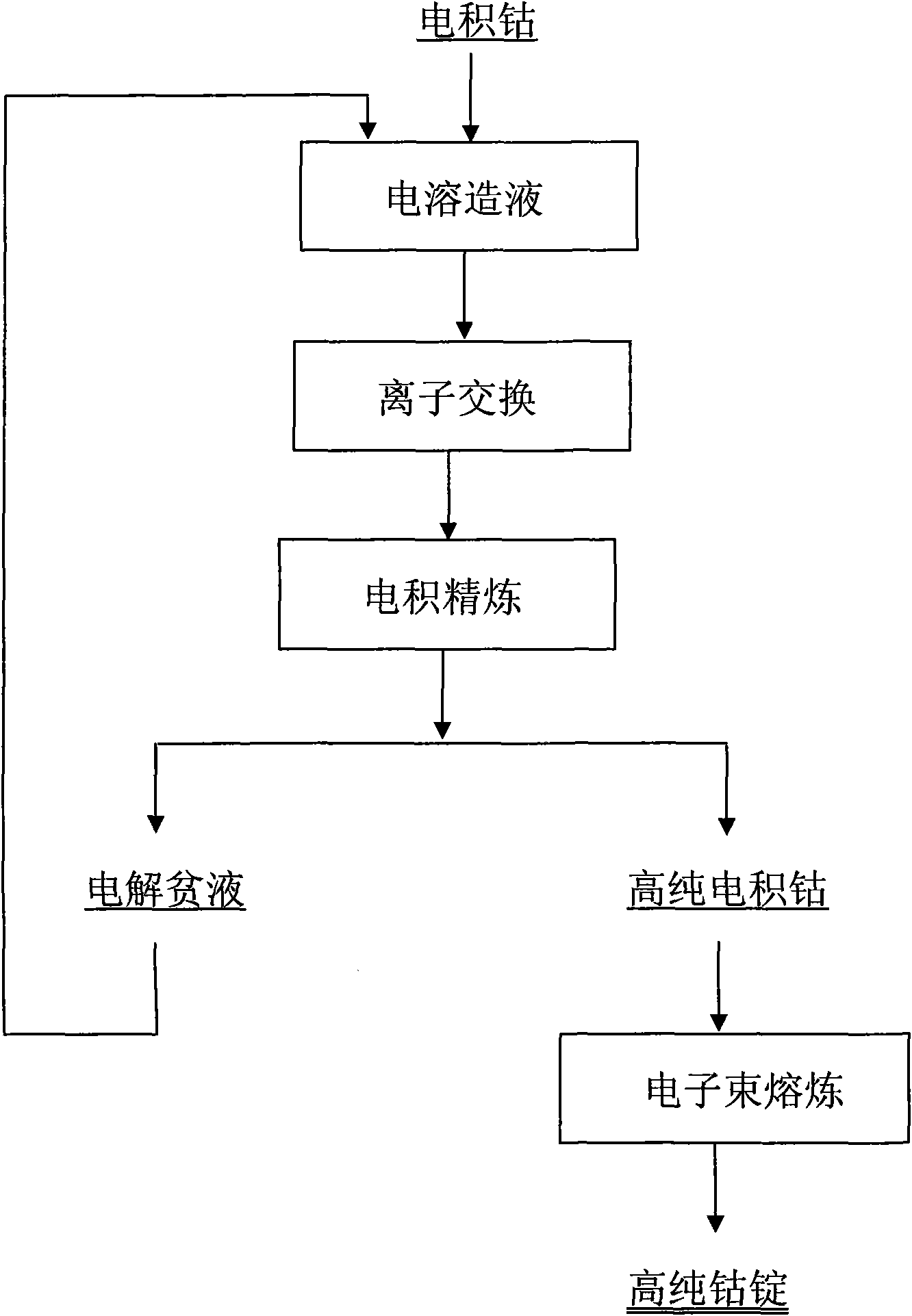

Method used

Image

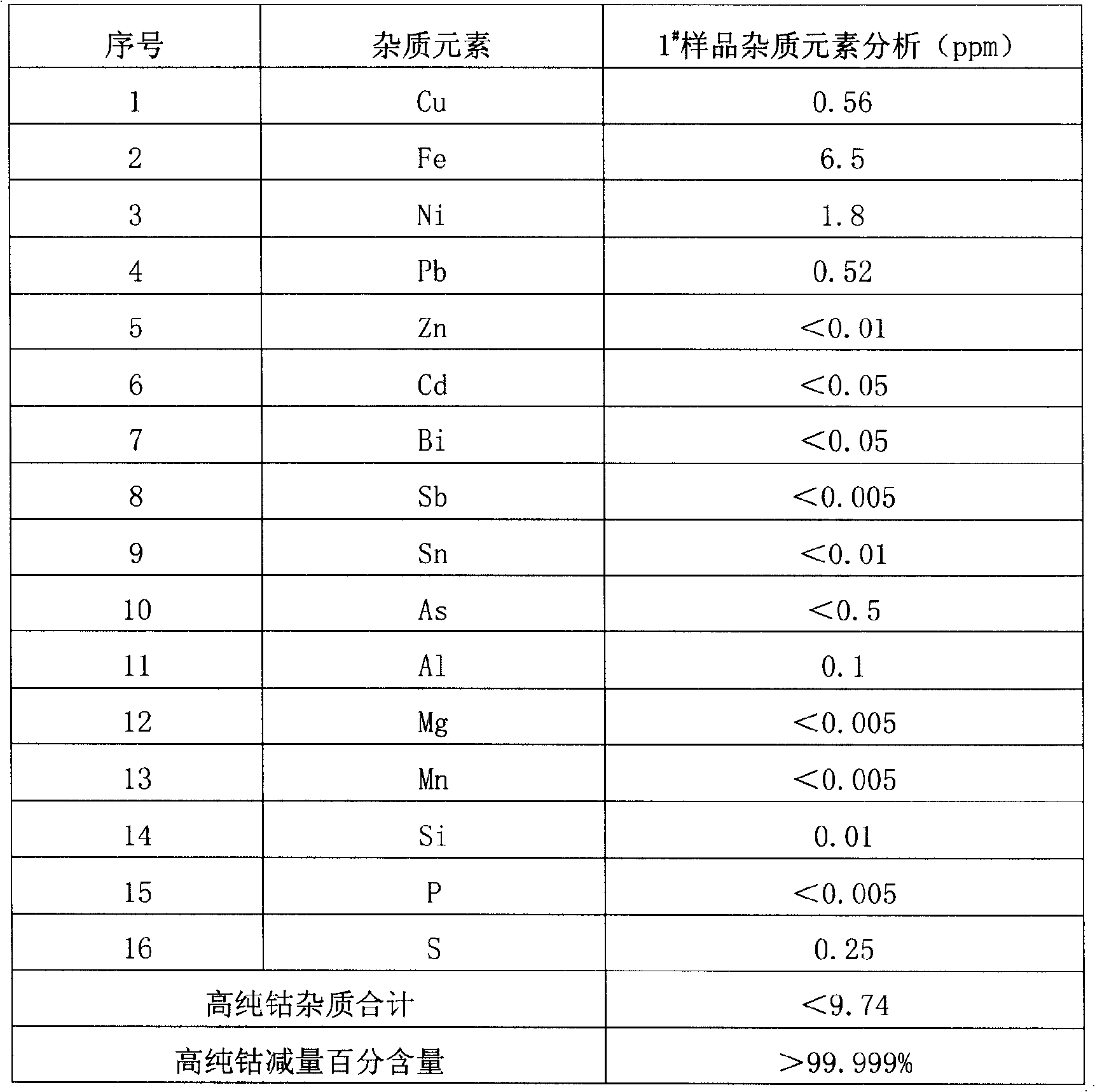

Examples

Embodiment 1

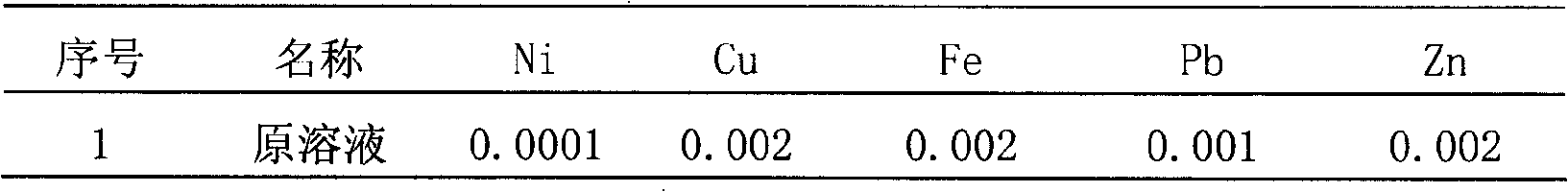

[0027] Using 99.95% electrolytic cobalt to prepare CoCl by electrolysis in hydrochloric acid system 2 solution with a current density of 150A / m 2 , electrodissolved into the solution of H + Use 30A / m at the end of liquid production with a concentration of 1g / l 2 The current density of the solution is used to make liquid, so that the pH of the solution is 3.5, and the content of impurity elements in the solution is shown in Table 1:

[0028] Table 1-Content of impurity elements in the original solution Unit: g / l

[0029]

[0030] The solution after electrolysis was sequentially passed into the ion exchange column of mixed anion exchange resins respectively anion exchange resin 331, 717, D301 and D401 to purify the solution. The exchange flow rate was controlled at 1BV / h.

[0031] Table 2-Content of impurity elements in the solution after ion exchange Unit: g / l

[0032] serial number

name

Ni

Cu

Fe

Pb

Zn

1

after ion exchange

...

Embodiment 2

[0041] Using 99.95% electrolytic cobalt to prepare CoCl by electrolysis in hydrochloric acid system 2 solution with a current density of 200A / m 2 , electrodissolved into the solution of H + 50A / m is used at the end of liquid production with a concentration of 1.5g / l 2 The current density of the solution was used to make liquid, so that the pH of the solution was 4.3, and the content of impurity elements in the solution was shown in Table 5.

[0042] Table 5-Content of impurity elements in the original solution Unit: g / l

[0043]

[0044] The solution after electrolysis was sequentially passed into the ion exchange column of mixed anion exchange resins respectively anion exchange resin 331, 717, D301 and D401 to purify the solution. The exchange flow rate was controlled at 1BV / h.

[0045] Table 6-The content of impurity elements in the solution after ion exchange Unit: g / l

[0046] serial number

name

Ni

Cu

Fe

Pb

Zn

1

after ion ...

Embodiment 3

[0055] Using 99.95% electrolytic cobalt to prepare CoCl by electrolysis in hydrochloric acid system 2 solution with a current density of 300A / m 2 , electrodissolved into the solution of H + 70A / m is used at the end of the liquid-making stage with a concentration of 2g / l 2 The current density of the solution is used to make liquid, so that the pH of the solution is 5, and the content of impurity elements in the solution is shown in Table 9.

[0056] Table 9-Content of impurity elements in the original solution Unit: g / l

[0057]

[0058] The solution after electrolysis was sequentially passed into the ion exchange column of mixed anion exchange resins, namely anion exchange resin 331, 717, D301 and D401, for concentration purification, and the exchange flow rate was controlled at 1BV / h.

[0059] Table 10-Content of impurity elements in the solution after ion exchange Unit: g / l

[0060] serial number

name

Ni

Cu

Fe

Pb

Zn

1

after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com