Heavy oil electronic control oil injector for low-speed diesel engine

An electronically controlled fuel injection and fuel injector technology, which is applied to machines/engines, mechanical equipment, engine components, etc., can solve problems such as device corrosion, and achieve the effect of improving cleanliness and preventing mutual pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

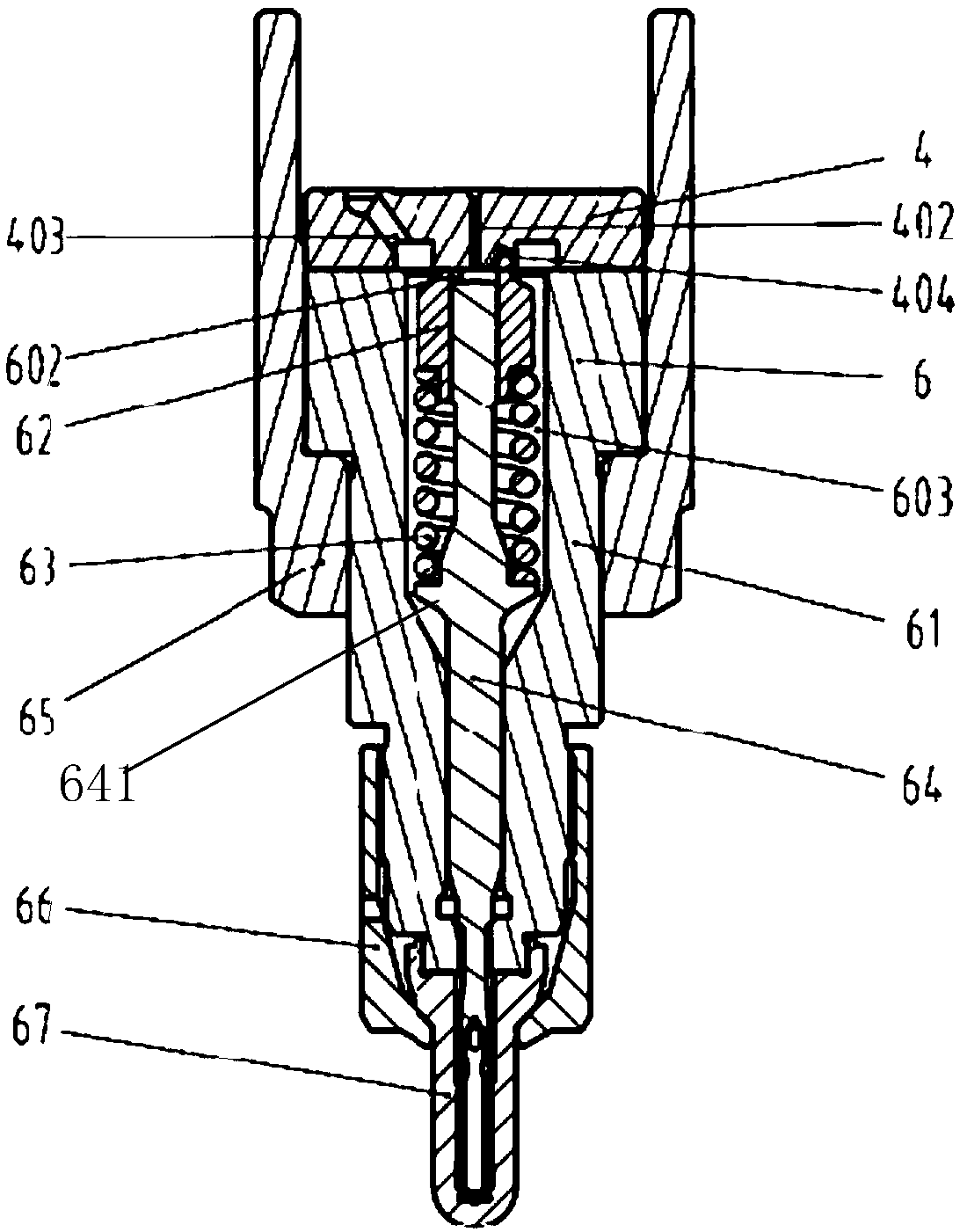

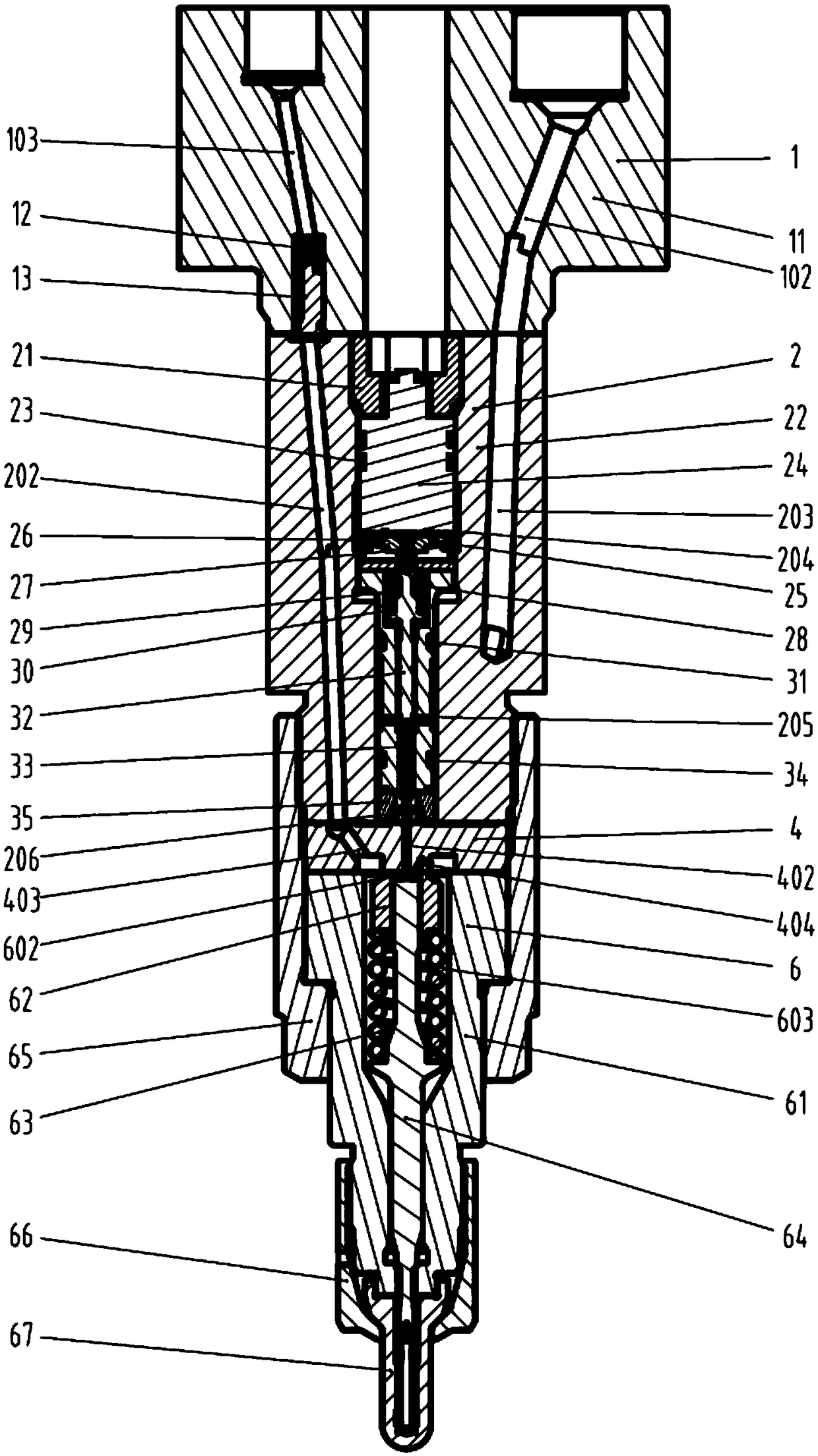

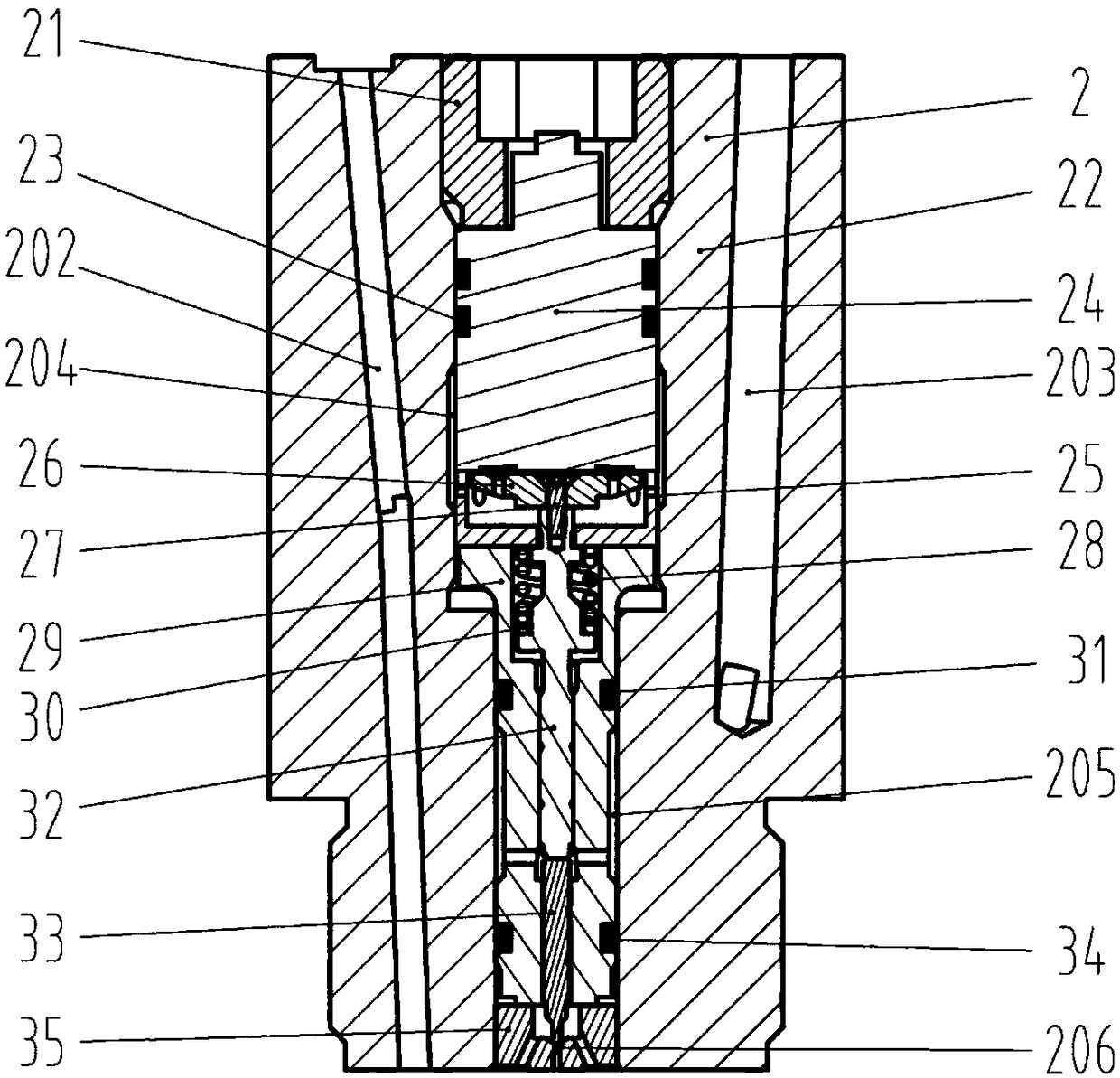

[0059] refer to Figure 1 to Figure 11 , the present invention provides a heavy oil electronically controlled injector for low-speed diesel engines, comprising: an injector upper body 11, an injector body 22, an oil inlet orifice plate 4, and a needle valve body arranged sequentially from top to bottom 61 and nozzle 67; the end face of the needle valve body 61 facing the oil inlet orifice 4 is respectively formed with a control volume cavity 602 and a high-pressure fuel cavity 603; the upper body 11 of the injector, the injector body 22 and the oil inlet orifice 4 are sequentially arranged to form an oil inlet passage, an oil return passage 207 and a circulating oil passage, and the outlet of the oil inlet passage is respectively connected to the control volume chamber 602 and the high-pressure fuel chamber 603, the circulating oil passage communicates with the high-pressure fuel chamber 603; the circulating oil passage is provided with a circulation valve that blocks or condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com