Clean separating method of Baotou rare-earth ore concentrate

A rare earth concentrate and separation method technology, applied in the direction of improving process efficiency, can solve the problems of incomplete understanding of the direction of non-rare earth impurities, backward roasting equipment, etc., and achieve simplified extraction and separation process, less interference from solvent extraction, and simplified separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

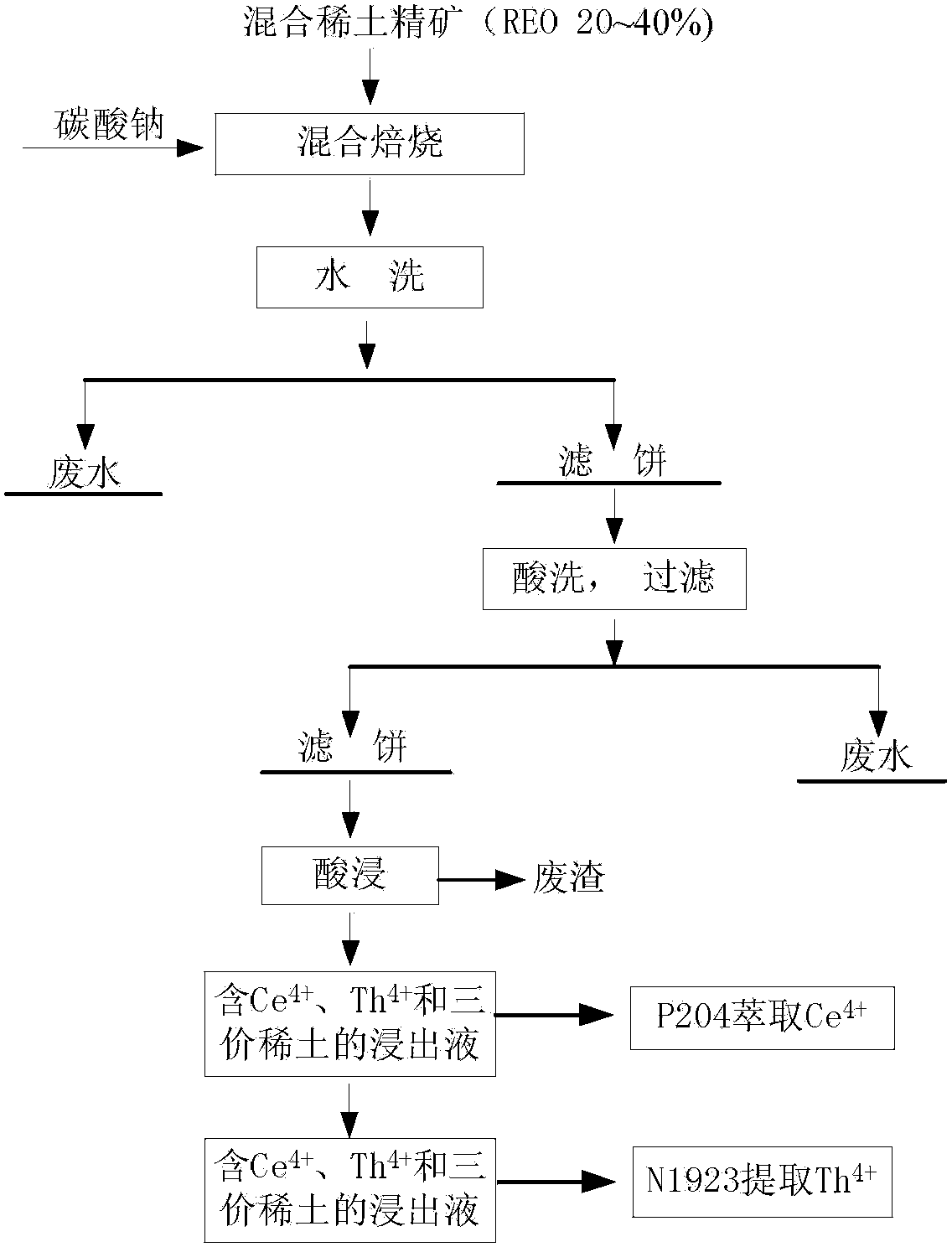

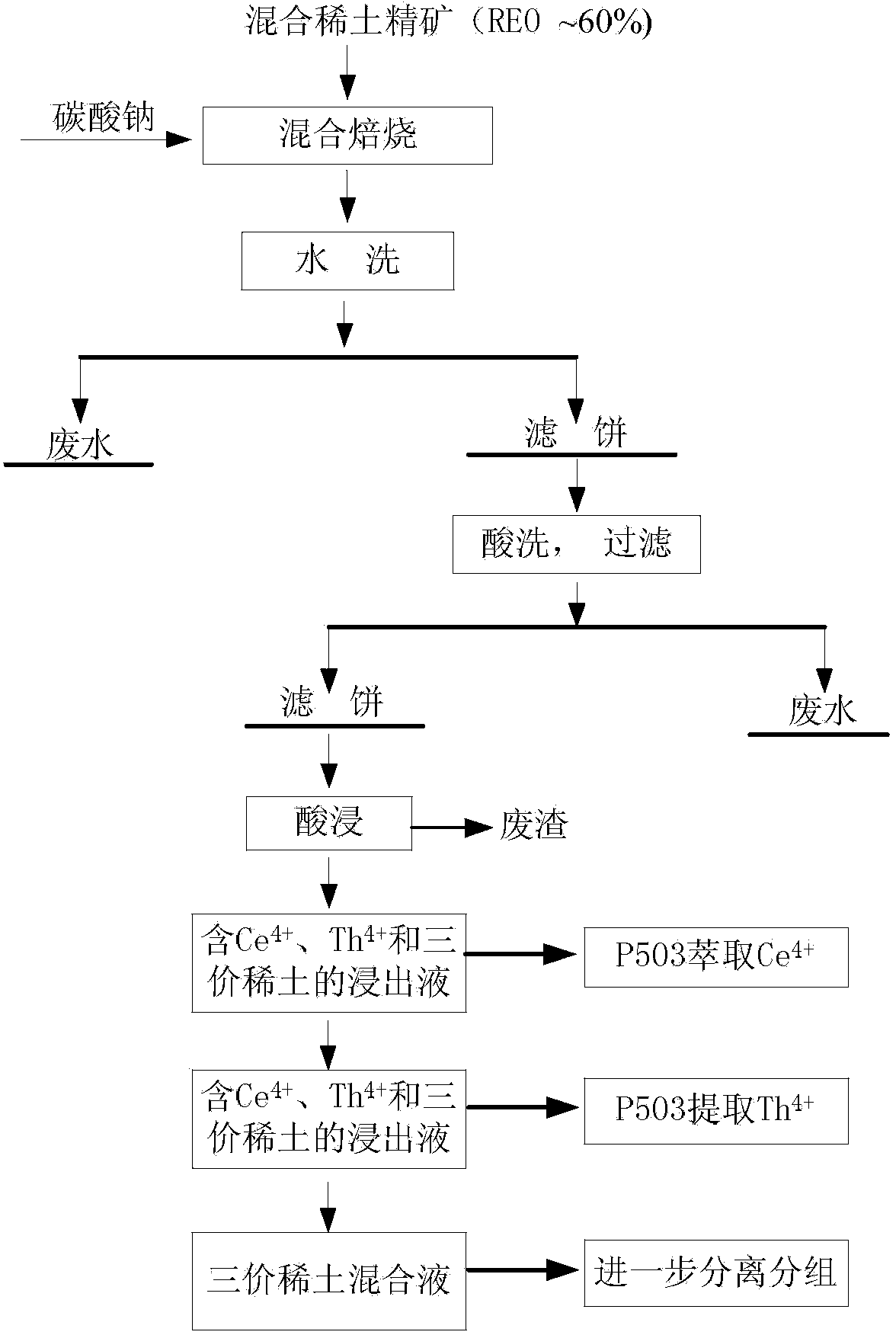

Method used

Image

Examples

Embodiment 1

[0054] The mixed rare earth concentrate (50% REO) was roasted with sodium carbonate, washed with water and pickled with 0.5 mol / L dilute hydrochloric acid, and then pickled with 5 mol / L nitric acid to obtain Ce-containing 4+ 、Th 4+ and the leaching solution of trivalent rare earth elements, using P503 extractant to extract Ce 4+ Th 4+ extraction, followed by separation of light rare earths.

[0055] Extraction of Ce with P503 Extractant 4+ The method is: use alkane solution with a volume ratio of 20~40%P503 as the extraction agent, after 5-8 stages of extraction, 7-10 stages of washing, 3~5 stages of countercurrent back extraction, the pH of the cerium stripping solution is adjusted to 1~2, add oxalic acid to precipitate cerium, wash the precipitate, and roast at 800~850°C for 0.5-2 hours to obtain CeO 2 Product, the purity is as high as 99.9%, ThO 2 / CeO 2 -4 .

[0056] Th extraction with P503 extractant 4+ The method is: use alkane solution with a volume ratio of 20-...

Embodiment 2

[0059] In Example 2, the mixed rare earth concentrate REO is 60%, and 0.5 mol / liter of dilute nitric acid is used for pickling, and the rest are the same as in Example 1.

Embodiment 3

[0061] In Example 3, the REO content of the mixed rare earth concentrate is 55%, and the mixed acid of 0.5 mol / L dilute sulfuric acid and dilute hydrochloric acid is used for pickling, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com