Improved process for preparing porous microsphere active carbon

A technology of porous microspheres and activated carbon, which is applied in the field of ultra-high-strength porous microsphere activated carbon, which can solve the problems of complex preparation process, low strength of spherical activated carbon, and difficulty in industrial production, and achieve high product strength, good fluidity and low impurity content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

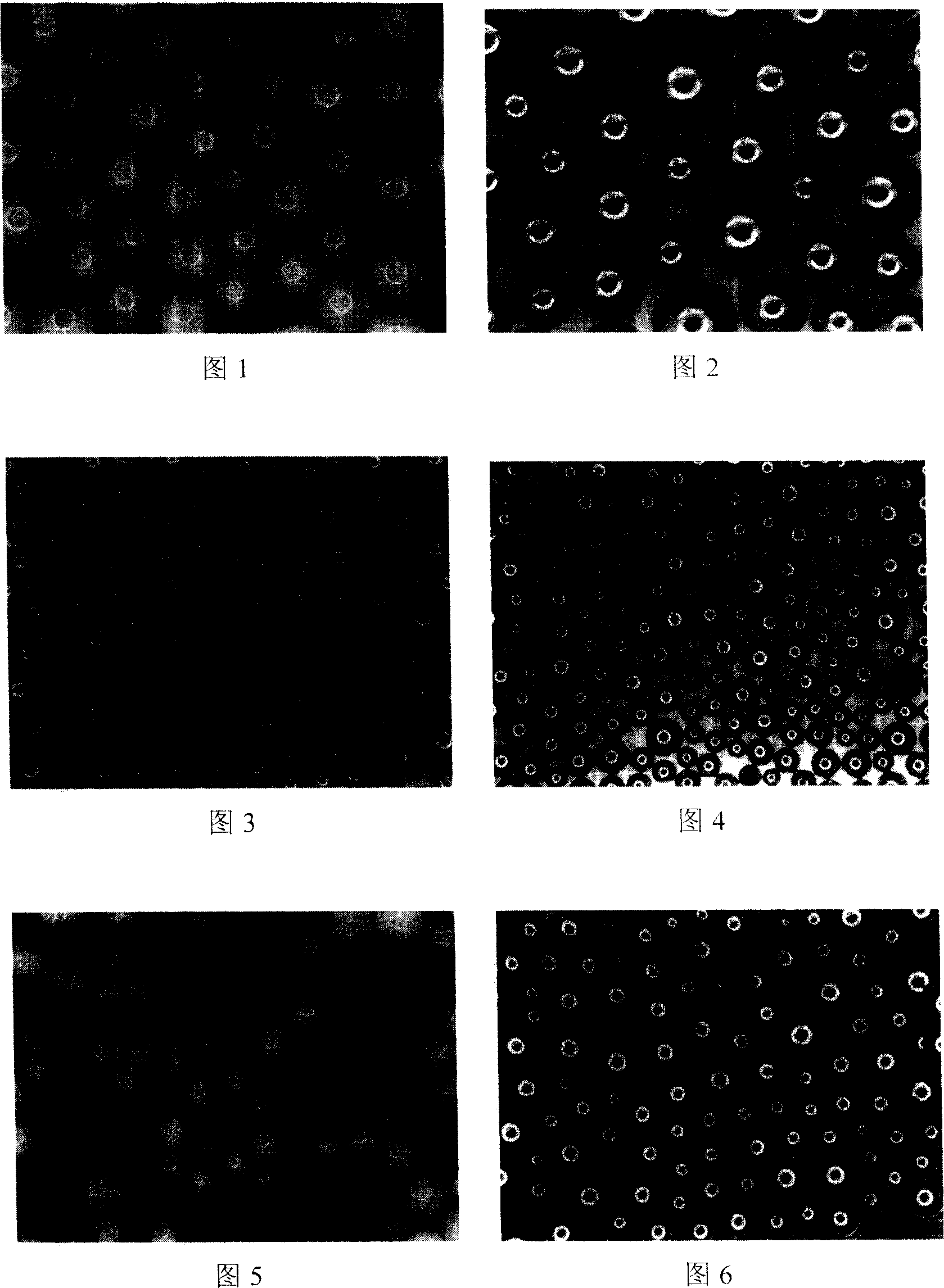

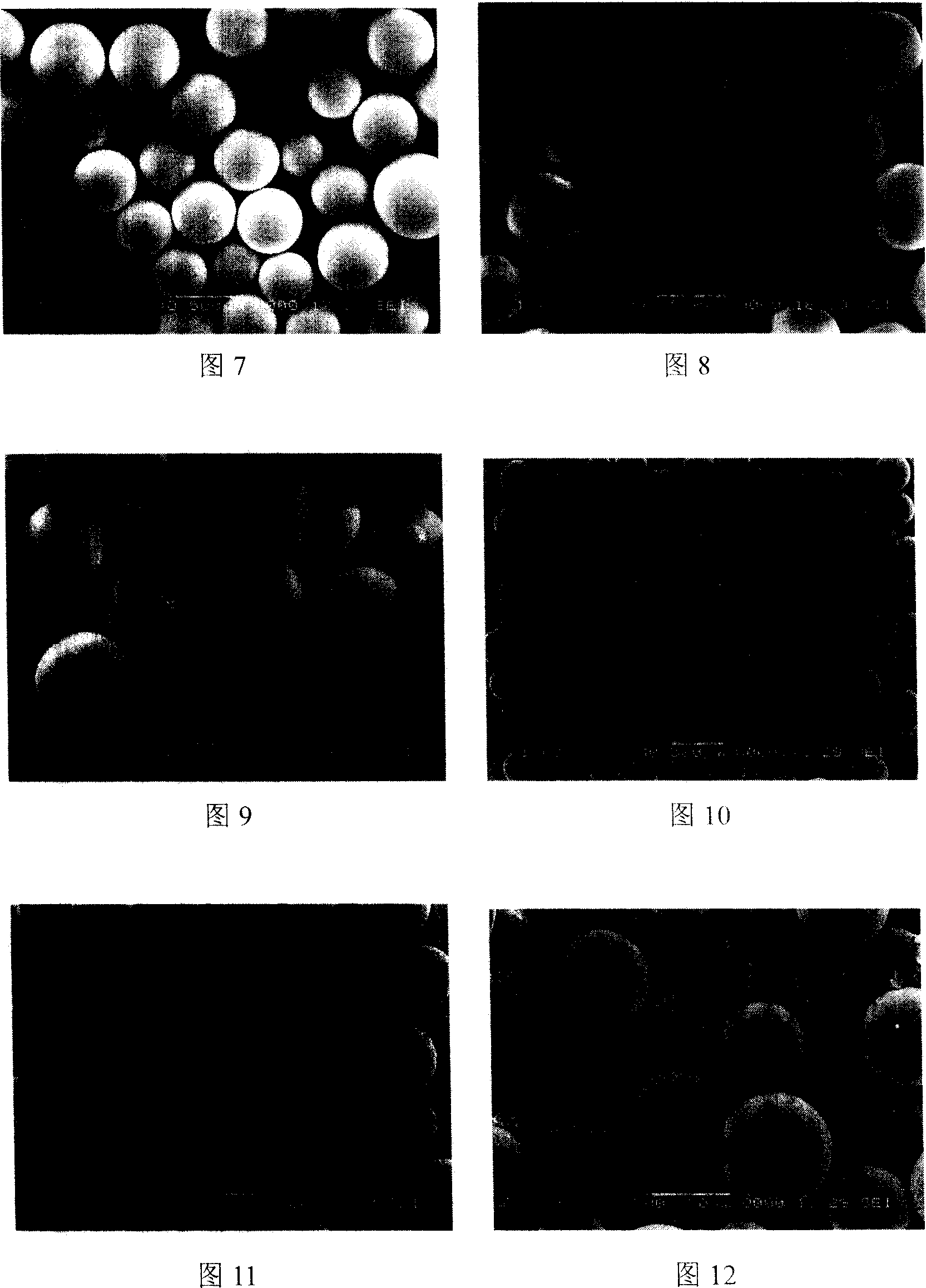

Image

Examples

Embodiment 1

[0036] 300 g of thermosetting phenolic resin balls were oxidized at a temperature of 80° C. for 10 hours in an atmosphere with an oxygen content of 40% by volume. Subsequently, the product obtained above was raised to 800° C. at a rate of 1° C. / min in an inert atmosphere of nitrogen, and stayed at this temperature for 2 hours for carbonization treatment. Subsequently, at 800° C., an activation treatment was carried out in an activation atmosphere of water vapor for 0.5 hours, and the ultra-high-strength porous microsphere activated carbon was obtained. The strengths of the resulting activated carbons are listed in Table 1 below.

Embodiment 2

[0038]200 g of thermosetting acrylic resin balls were oxidized at a temperature of 150° C. for 4 hours in an atmosphere with an oxygen content of 30% by volume. The product obtained above was raised to 600° C. at a rate of 1° C. / min in an inert atmosphere of nitrogen, and stayed at this temperature for 3 hours for carbonization treatment. Subsequently, at 600° C., the activation treatment was carried out under the activation atmosphere of water vapor for 1 hour, and the ultra-high-strength porous microsphere activated carbon was obtained. The resulting activated carbon strengths are listed in Table 1 below.

Embodiment 3

[0040] 300 g of thermosetting methacrylic resin balls were oxidized with concentrated sulfuric acid at 80° C. for 10 hours. After drying at 120°C, the product obtained above was raised to 1000°C at a rate of 3°C / min in an inert atmosphere of nitrogen, and stayed at this temperature for 1 hour for carbonization. Subsequently, at 1000° C., an activation treatment is carried out under an activation atmosphere of water vapor for 0.5 hours to obtain ultra-high-strength porous microsphere activated carbon. The resulting activated carbon strengths are listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com