Method for preparing waterproof and oilproof ceramic coating on surface of base material

A technology for ceramic coatings and substrate surfaces, applied in the direction of coatings, etc., can solve difficult and complex problems in industrial application, and achieve excellent waterproof and oil-proof performance, convenient operation, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

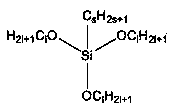

Method used

Image

Examples

Embodiment 1

[0027] Under the protection of nitrogen, tetraethyl orthosilicate component A, silica sol component B, silane coupling agent component C with fluorocarbon chain substitution, and long carbon chain silane coupling agent component D were mixed at 10 Mix evenly at ℃, add catalyst E, hydrolyze and condense at 40℃ for 1 hour to prepare a fluorine-silicon modified ceramic coating, in which the mass ratio of components A, B, C, D, and E is 1:0.20:0.15 :0.05:0.1;

[0028] Spin-coat the fluorine-silicon-modified ceramic coating prepared above to the surface of a glass slide treated by soaking in alkaline absolute ethanol with pH 9 for 3 days, control the spin-coating speed to be 1000rpm, and spin-coat for 30s, and then After heat treatment at 80°C for 3 hours, a waterproof and oil-proof glass slide surface can be obtained.

[0029] In this example, the silica sol component B is a silica ethanol sol with a pH=2, a solid content of 5%, and a particle size of 10-100 nm, and the silane co...

Embodiment 2

[0031] Under the protection of nitrogen, tetraethyl orthosilicate component A, silica sol component B, silane coupling agent component C with fluorocarbon chain substitution, and long carbon chain silane coupling agent component D were mixed at 12 Mix evenly at ℃, add catalyst E, and perform hydrolysis and condensation reaction at 45℃ for 1.5 hours to prepare fluorine-silicon modified ceramic coatings, in which the mass ratio of components A, B, C, D, and E is 1:0.31:0.18: 0.06:0.2;

[0032] Spin-coat the above-mentioned fluorine-silicon-modified ceramic coating onto the surface of a silicon wafer treated by soaking in alkaline absolute ethanol with a pH of 9 for 3 days, control the spin-coating speed to be 1500rpm, and spin-coat for 35s, and then After heat treatment at 100°C for 4 hours, a waterproof and oil-resistant silicon wafer surface can be obtained.

[0033] In this example, the silica sol component B is a silica propanol solution with a pH=4, a solid content of 10%,...

Embodiment 3

[0035] Under the protection of nitrogen, tetraethyl orthosilicate component A, silica sol component B, silane coupling agent component C with fluorocarbon chain substitution, and long carbon chain silane coupling agent component D were mixed at 14 Mix evenly at ℃, add catalyst E, and perform hydrolysis and condensation reaction at 50℃ for 2 hours to prepare fluorine-silicon modified ceramic coating, wherein the mass ratio of components A, B, C, D, and E is 1:0.35:0.22: 0.08:0.2;

[0036] Spin-coat the fluorine-silicon-modified ceramic coating prepared above to the surface of the iron sheet that is soaked in alkaline absolute ethanol with pH 10 for 3 days, control the spin-coating speed to be 1800rpm, and spin-coating time is 40s, and then After heat treatment at 120°C for 5 hours, the surface of the waterproof and oil-proof iron sheet can be obtained.

[0037] In this example, silica sol component B is a silica methanol solution with pH = 6, a solid content of 30%, and a part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com