Method for preparing black ceramic membrane by magnesium alloy differential arc oxidation

A technology of micro-arc oxidation and black ceramics, applied in the direction of anodic oxidation, etc., can solve the problems such as no relevant literature can be found, achieve good corrosion resistance, expand the application field, and achieve the effect of high blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] I. The reagents used are:

[0041] The main film-forming agent is sodium silicate, the chemical formula is: Na 2 SiO 3 9H 2 O,

[0042] The film-forming auxiliary agent is potassium fluoride, the chemical formula is: KF·2H 2 O,

[0043] The pH regulator is potassium hydroxide, the chemical formula is: KOH,

[0044] Complexing agent B: ammonia water,

[0045] Colorant A: copper sulfate pentahydrate,

[0046] II. The equipment used is:

[0047] MAO120HD-II micro-arc oxidation device developed by Xi'an University of Technology. The device is mainly composed of power supply and control system, oxidation tank, stirring system and cooling system.

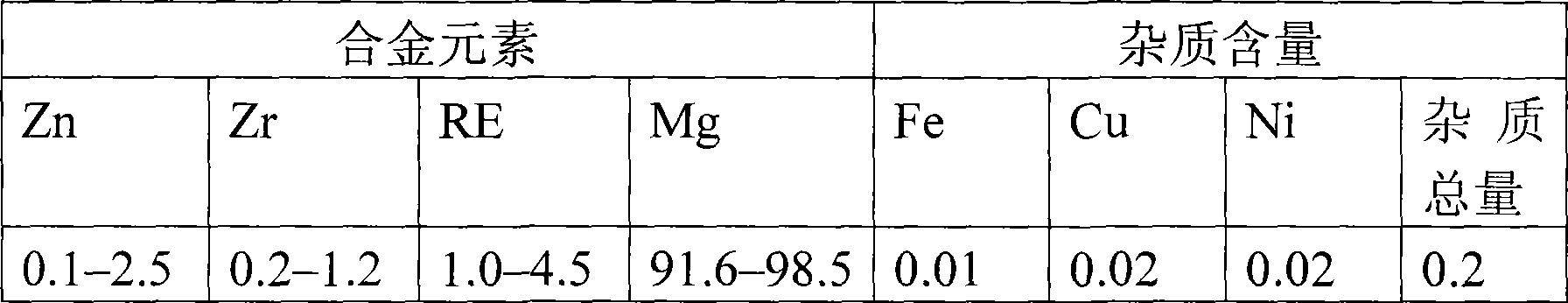

[0048] The rare earth magnesium alloy material is: SJDM-1 rare earth magnesium alloy; the main composition (W%) is shown in Table 1.

[0049] Table 1 SJDM-1 rare earth magnesium alloy chemical composition (Wt%)

[0050]

[0051] III. Preparation of MAO coloring treatment solution

[0052] First take distilled water a...

Embodiment 2

[0065] 1, the reagent used is with embodiment 1.

[0066] II, the equipment used is as embodiment 1.

[0067] The rare earth magnesium alloy material is as in Example 1.

[0068] III. Preparation of MAO coloring treatment solution

[0069] First take distilled water and pour it into the equipment, add reagents at room temperature, the order and concentration range of reagents are: sodium silicate (Na 2 SiO 3 9H 2 O) is 7g / L, potassium fluoride (KF 2H 2 O) is 7g / L, and potassium hydroxide (KOH) is 8g / L, constantly stirs during adding, treats that a kind of reagent dissolves fully and then adds another kind of reagent, after adding, stir until reagent dissolves completely; After dissolving 2.2g of coloring agent A in water, add complexing agent B to make the concentration 45ml / L, let it stand for 10min-30min, then add it into the prepared solution above, and continue to stir until it is evenly mixed.

[0070] IV. Implementation of MAO process

[0071] 1) Degreasing and cl...

Embodiment 3

[0082] 1, the reagent used is with embodiment 1.

[0083] II, the equipment used is as embodiment 1.

[0084] The rare earth magnesium alloy material is as in Example 1.

[0085] III. Preparation of MAO coloring treatment solution

[0086] First take part of the distilled water and pour it into the equipment, then add the reagents at room temperature, the order and concentration range of the reagents are: sodium silicate (Na 2 SiO 3 9H 2 O) is 8g / L, potassium fluoride (KF 2H 2 O) is 7g / L, and potassium hydroxide (KOH) is 7g / L. Stir continuously during the addition process. After one reagent is completely dissolved, add another reagent. After adding, stir until the reagent is completely dissolved; dissolve Add colorant A to make the concentration 2.6g / l, add B to make the concentration 50ml / L, let it stand for 10min-30min, then add it to the prepared solution above, and continue to stir until the mixture is uniform.

[0087] IV. Implementation of MAO process

[0088] 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com