Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

409results about How to "Reasonable production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lady beer and production technology thereof

The invention relates to a beer produced from materials of 1-7 degree beerwort produced with a common beer production method, fresh fruit and vegetable juice, healthcare plant juice, traditional Chinese medicine extract, vitamins, a microelement mineral preparation, a foam stabilizer, and ethanol, which are blended according to a certain weight ratio. The lady beer provided by the invention has characteristics of digestion and absorbance promoting, beautifying, toxin expelling, freckle reducing, weight reducing, aging resisting, fatigue resisting, bowel loosening, constipation relieving, metabolism balancing, endocrine regulating, blood sugar reducing, and blood fat reducing. The contents of beerwort and ethanol in the beer are low. With the lady beer, original flavors of beer are preserved, abundant nutrients are provided, beer belly is not caused with long-term drinking, obesity is not caused, and a good healthcare effect is provided. The application scope of the lady beer is wide, and the lady beer is especially suitable for ladies.

Owner:张华

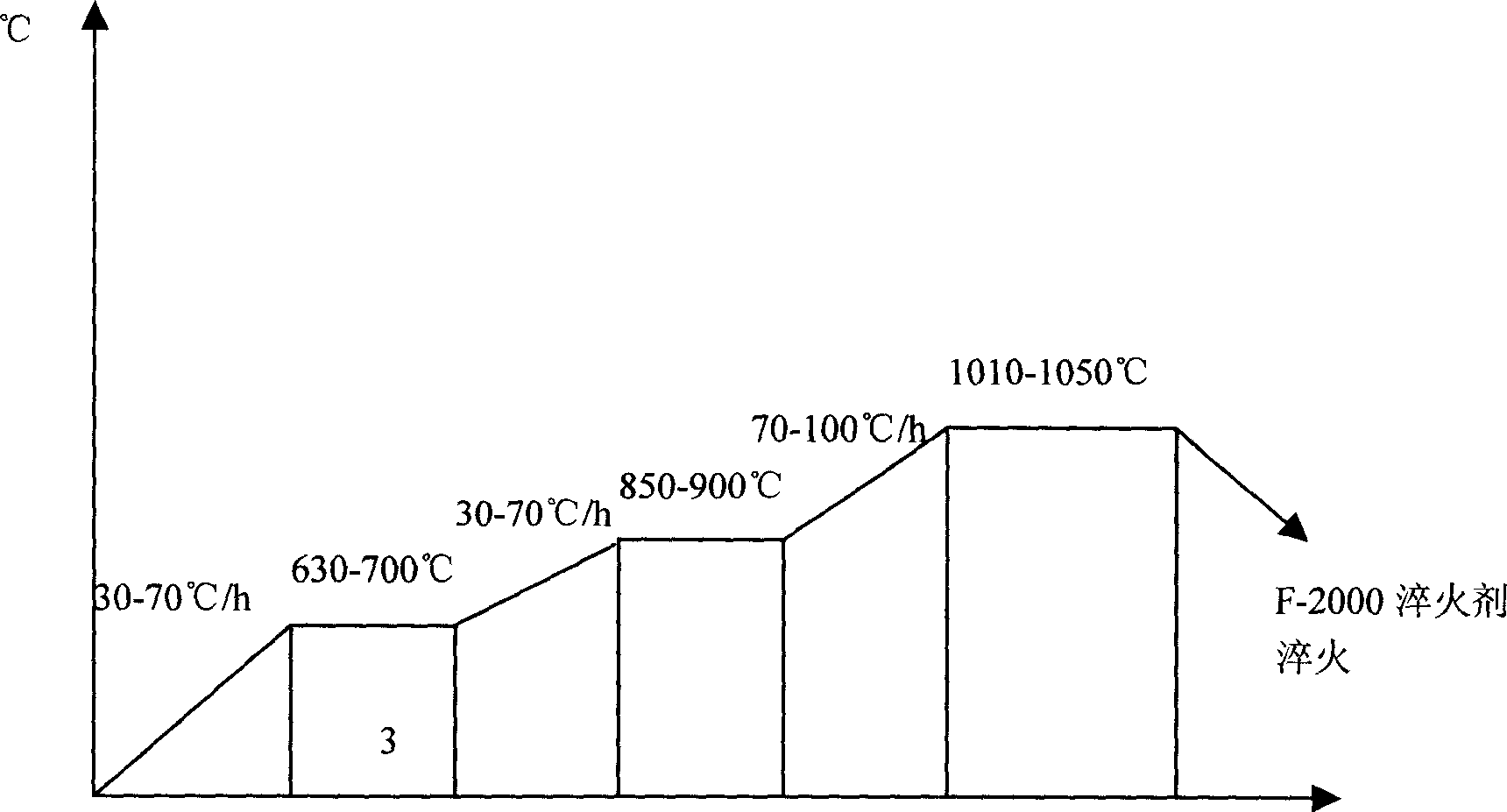

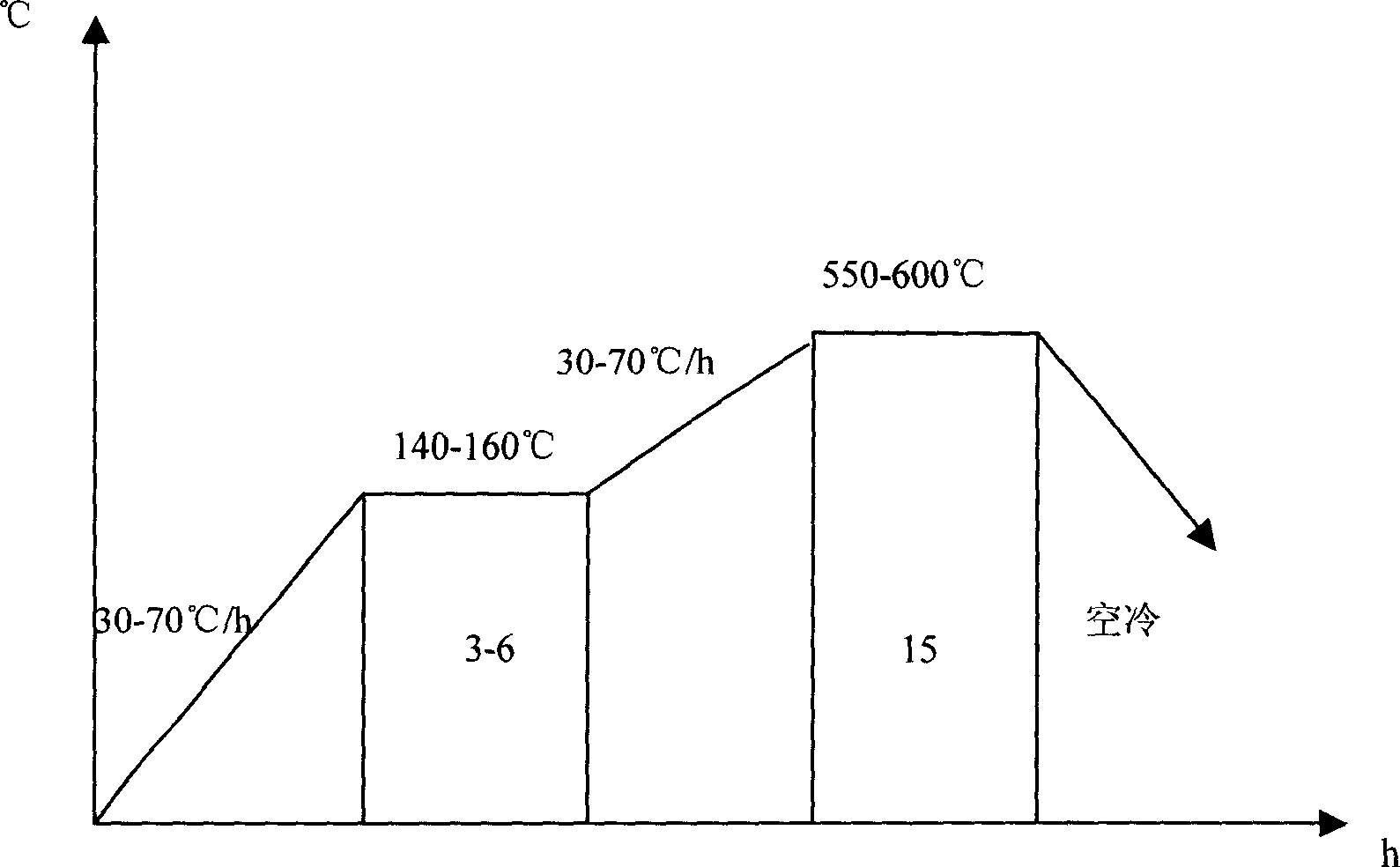

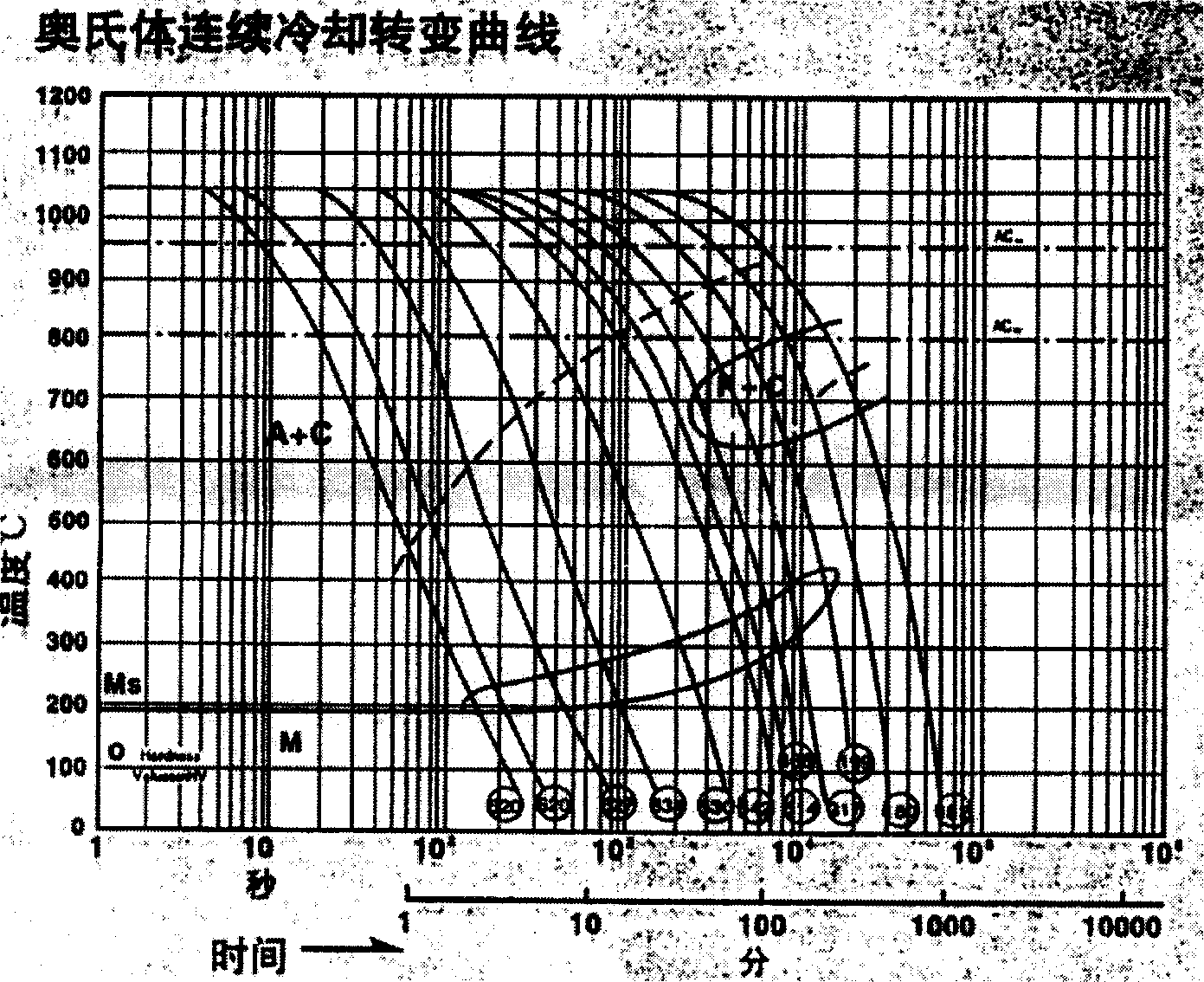

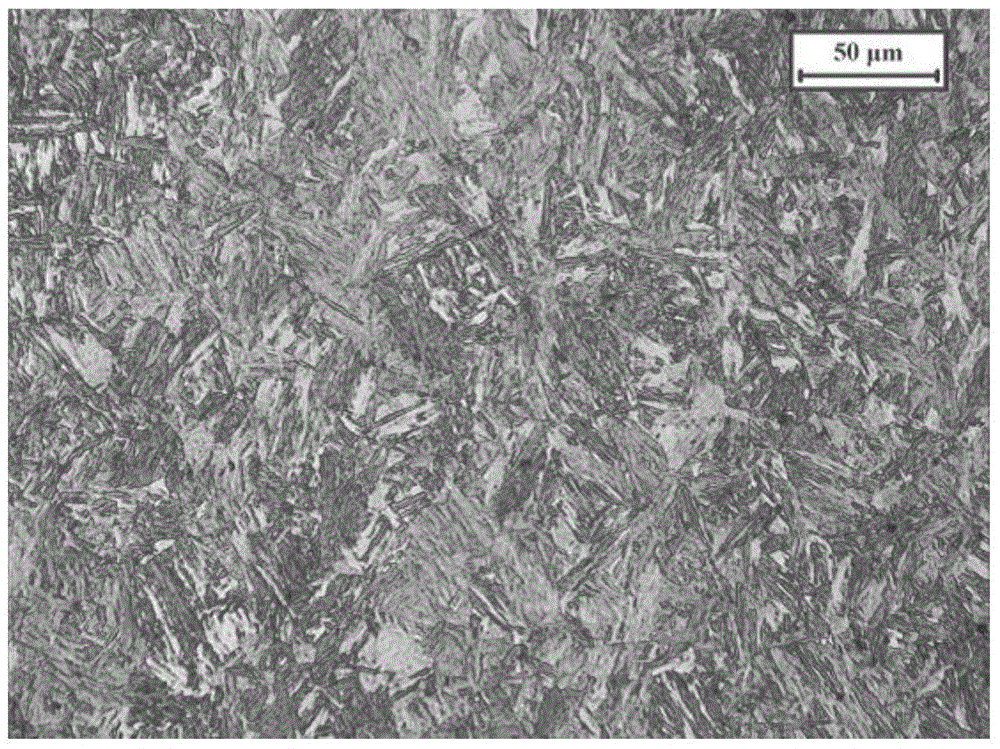

Anticorrosion, wear-resistant plastic die steel 4Cr16Mo and its mirror large-die-block preparing and producing method

ActiveCN1676653AImprove lateral performanceMeet mirror polishing requirementsHeat treatment process controlProcess efficiency improvementChemical compositionWear resistant

It is a new preparation and production method of corrosion-resistant and anti-abrasive plastic die steel 4Cr16Mo and its big mirror module. The characteristic is about its chemical composition. There are 0.33-0.43%C, 0.30-1.00%Mn, 0.30-1.00%Si, less than 0.045%S, less than 0.045%P, 14-18%Cr, 0.10-1.00%Ni, 0.80-1.50%Mo besides Fe. The method includes double refinement consisting of the primer smelting in electric furnace and vacuum handling outside the furnace and electroslag remelting, and necessary stress relieving annealing static ingot and electroslag ingot to refine electroslag ingot of component-uniform. After that, it uses hot machining forging technology and necessary stress relieving annealing of module to make the electroslag ingot into big module (thickness: 500mm, width:1200mm, length: 2500mm). At last, special heat-treat module modified treatment technology is used to bring out big highly corrosion-resistant and highly anti-abrasive plastic die steel module. This kind of module has stable quality and the nature reaching the standard(dirty component A<=2.0, B<=2.0, C thinness<=2.0, C thickness<=1.5, D<=2.0). To sum up, it has significant economic and social efficiency.

Owner:宝武特种冶金有限公司

Environment-friendly type aqueous aluminum foil protecting agent and preparation thereof

InactiveCN101407655ALow VOC contentReduce manufacturing costPolyurea/polyurethane coatingsPolyamide coatingsGeneral purposeOrganosolv

The invention relates to an environmental-friendly waterborne aluminum foil protective agent and a prepration method thereof, wherein, the protective agent comprises the following components according to the formula by weight: 45 percent to 70 percent main resin; 0 percent to 20 percent assisted resin; 10 percent to 50 percent water; 0 percent to 35 percent cosolvent; 0 percent to 0.5 percent film-forming auxiliary agent; 0 percent to 0.5 percent leveling agent; 0 percent to 0.5 percent defoamer; 0 percent to 2 percent anti-abrasion agent; and 0 percent to 0.5 percent pH regulator. Compared with the prior art, the environmental-friendly waterborne aluminum foil protective agent and the prepration method have the advantages: (1) the aluminum foil protective agent contains no organic solvent which is harmful to human body and has very low content of VOC, and water and ethanol are used for dilution during the using process, thereby being non-toxic and low in production cost; (2) the aluminum foil protective agent has good adhesion, good transparency, high smoothness and high thermal resistance performance; (3) the aluminum foil protective agent belongs to the general purpose products, and the range of application is broad; and (4) the production process is reasonable, the operation is simple and the production efficiency is high.

Owner:SHANGHAI WEIKAI CHEM

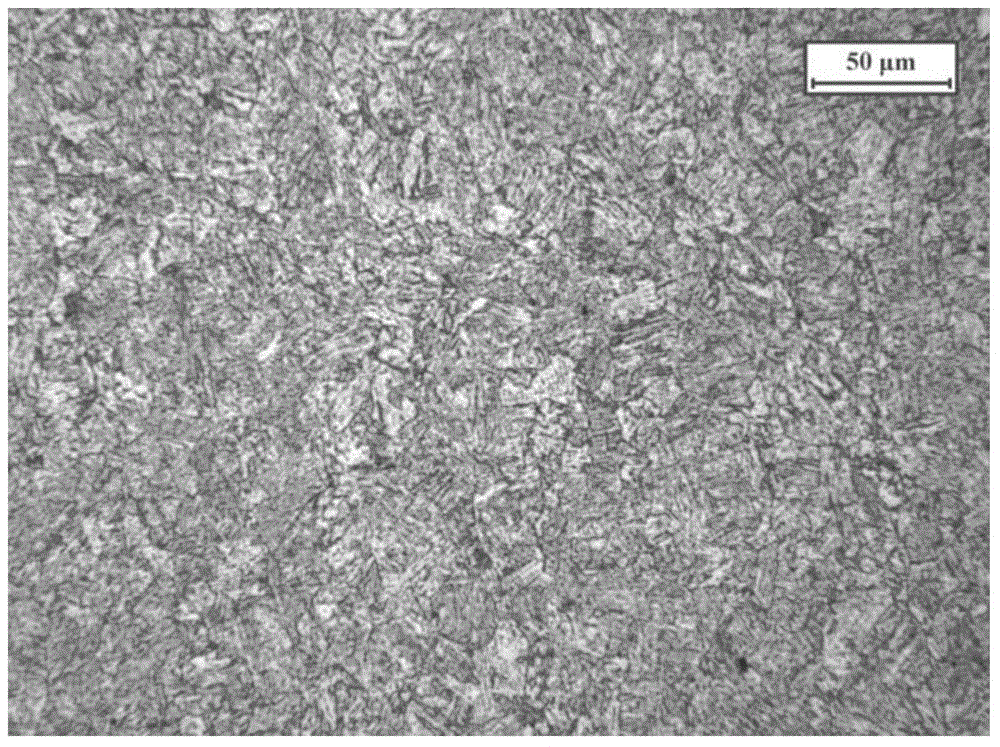

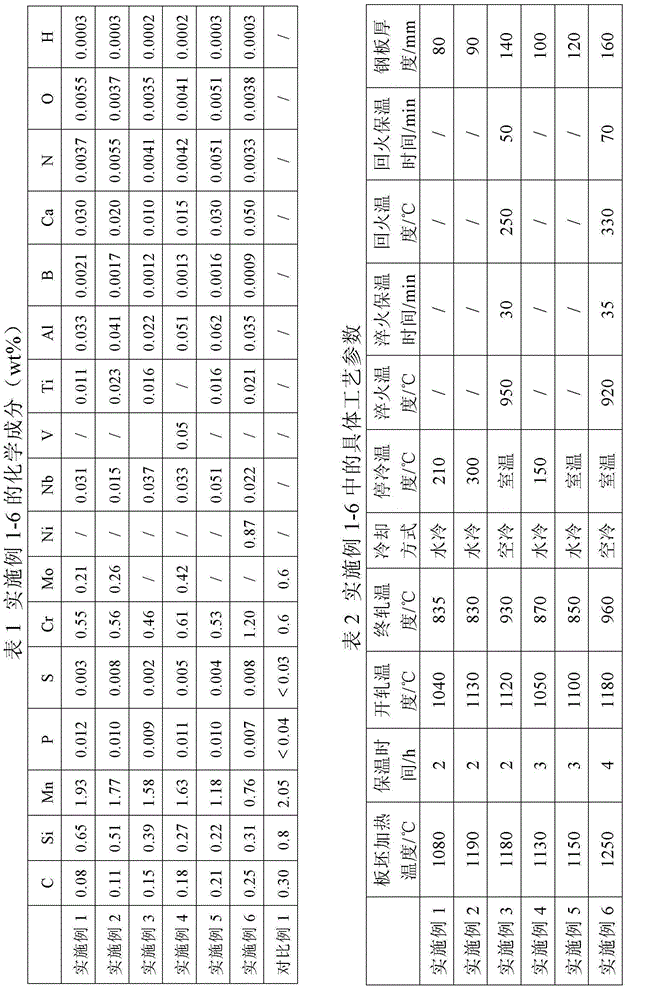

Low-alloy high-strength high-toughness steel plate and manufacturing method thereof

InactiveCN104480406AUniform compositionImprove surface qualityMetal rolling arrangementsAlloyHardness

The invention relates to a low-alloy high-strength high-toughness steel plate and a manufacturing method thereof. The low-alloy high-strength high-toughness steel plate comprises the following components in percentage by mass: 0.08-0.25% of C, 0.10-1.00% of Si, 0.50-2.00% of Mn, less than 0.020% of P, less than 0.010% of S, 0.10-2.00% of Cr, 0-1.00% of Mo, 0-2.00% of Ni, 0.010-0.080% of Nb, at most 0.10% of V, at most 0.060% of Ti, 0.0005-0.0040% of B, 0.010-0.080% of Al, 0.010-0.080% of Ca, at most 0.0080% of N, at most 0.0080% of O, at most 0.0004% of H, and the balance of Fe and inevitable impurities. 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%. The Brinell Hardness of the steel plate is 390-460 HB, the yield strength is 900-1100 MPa, the tensile strength is 1100-1400 MPa, the elongation percentage is 11-15%, the -40 DEG C Charpy V-notch longitudinal impact work is greater than or equal to 40J, and the plate thickness can reach 100mm above. Thus, the steel plate implements matching of high strength, high hardness and high toughness, and has favorable machining properties.

Owner:BAOSHAN IRON & STEEL CO LTD

Hot melt adhesive

InactiveCN102653665ASuitable for production process requirementsReasonable formula designMacromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a hot melt adhesive which comprises the following components in parts by mass: 5-10 parts of EVA (ethylene-co-vinyl acetate), 2-6 parts of tackifier, 5-10 parts of diluent, 0.5-1.5 parts of antioxidant and 0.5-1.5 parts of plasticizer. The tackifier is one of rosin resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent includes one or both of wax and low-molecular polyolefin; the antioxidant is phenolic antioxidant; and the plasticizer is DCHP (Dicyclohexyl phthalate). The EVA contains 20-30% of vinyl acetate monomer; and the wax is microcrystalline wax with molecular weight of 3,000-4,000 and melting point of 65-85 DEG C.

Owner:成都鑫三洋科技发展有限公司

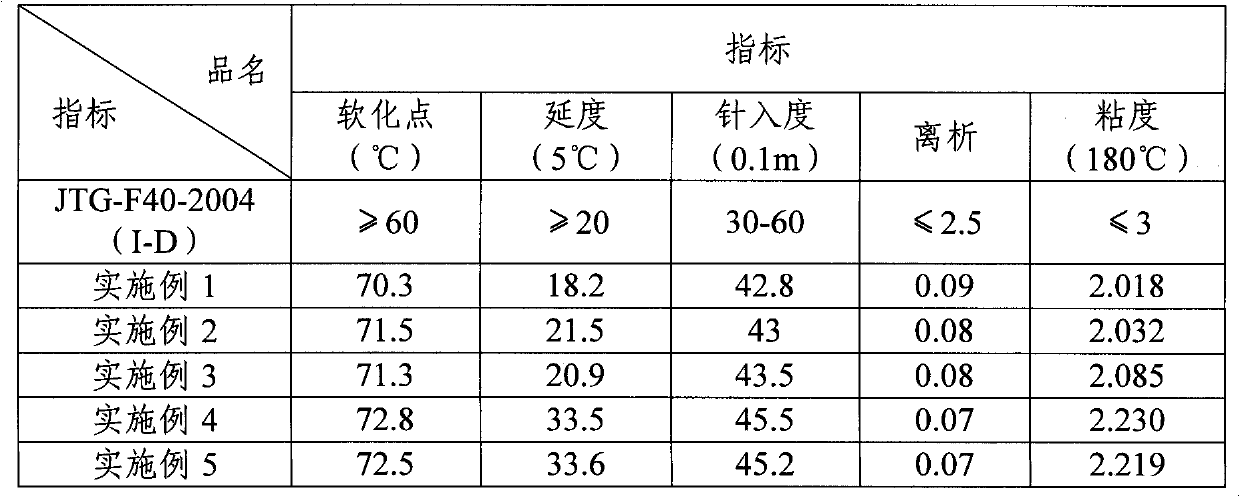

Waste rubber powder/styrene-butadiene-styrene (SBS) composite modified asphalt and production process thereof

InactiveCN102181163ASimple production processReduce energy consumptionBuilding insulationsDuctilityButadiene-styrene rubber

The invention discloses a waste rubber powder / styrene-butadiene-styrene (SBS) composite modified asphalt and a production process thereof. The waste rubber powder / SBS composite modified asphalt comprises 0.03 weight percent of activating agent, 0.1 weight percent of penetrating agent, 15 to 25 weight percent of waste rubber powder, 0.1 to 0.4 weight percent of SBS, 1 to 4 weight percent of aromatic oil and the balance of base asphalt. The preparation process of the modified asphalt comprises the following steps of: heating and melting the base asphalt at high temperature, adding the penetrating agent, the waste rubber powder, SBS, the aromatic oil and the activating agent into the base asphalt, stirring and swelling, and performing cyclic shear by using a high-speed shearing machine to obtain the waste rubber powder / SBS composite modified asphalt. The waste rubber powder / SBS composite modified asphalt has the characteristics of high softening point, high ductility and the like, and low cost. The production process of the waste rubber powder / SBS composite modified asphalt is simple and reasonable and is low in energy consumption.

Owner:JIANGYIN TAIFU ASPHALTUM

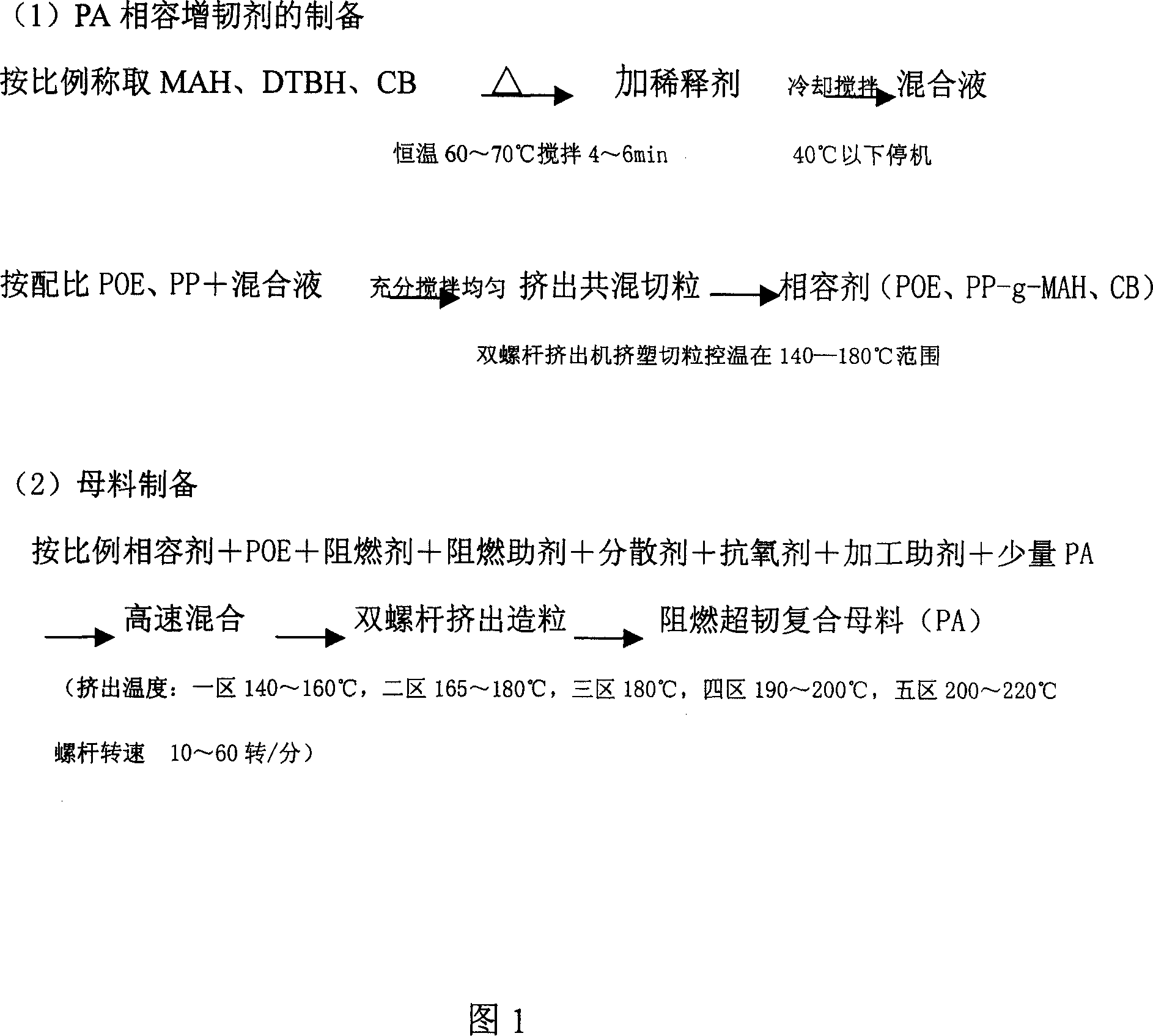

Production of super-toughened fire-retardant composite modified nylon mother material

Production of composite fire-retardant and ultra-toughed modified Nylon base material is carried out by preparing Nylon compatible toughening agent, weighing maleic anhydride, bis-penta vulcanizing agent and grafting accessory proportionally, adding into diluting agent, agitating, cooling to normal temperature to prepare into mixed liquid, extruding for multi-polymer of ethane-octylene, poly-propylene and mixed liquid by bi-screw extruder, granulating to obtain Nylon compatible toughening agent, extruding for multi-polymer of ethane-octylene, fire-retardant agent, dispersant, antioxidant and processing accessory, and granulating to obtain final product. It's convenient, cheap, fast and efficient and saves resources.

Owner:张发饶

Pouring material for manufacturing pellet ore rotary kiln and manufacturing method thereof

The invention relates to a casting material used for producing pellet rotary kiln and a preparation method thereof, the casting material is a combination, and contained components and weight percentage occupied in the combination contain: 70 to 92 percent of casting material basal body, 3 to 8 percent of micro powder of monox or micro powder of alumina, 0.001 to 5 percent of zirconium mullite or zirconite, 1 to 12 percent of carborundum, 0.005 to 5 percent calcium aluminate cement and 0.01 to 1 percent of dispersant; the casting material basal body is the combination of one or several of corundum, bauxite and porzite. The preparation method of the casting material has the following steps: first uniformly mixing the casting material basal body, then adding other components to be uniformly mixed, and finishing goods. The casting material contains the carborundum, the carborundum has the characteristic of difficult infiltration with furnace burden containing iron, and ring formation materials are difficult to be felted on a furnace brick lining; in addition, the carborundum can increase acidic furnace burden anti-corrosion performance of the casting material, and thus the life of the rotary kiln is enhanced. The preparation method of the casting material is simple and has low cost.

Owner:武钢集团有限公司

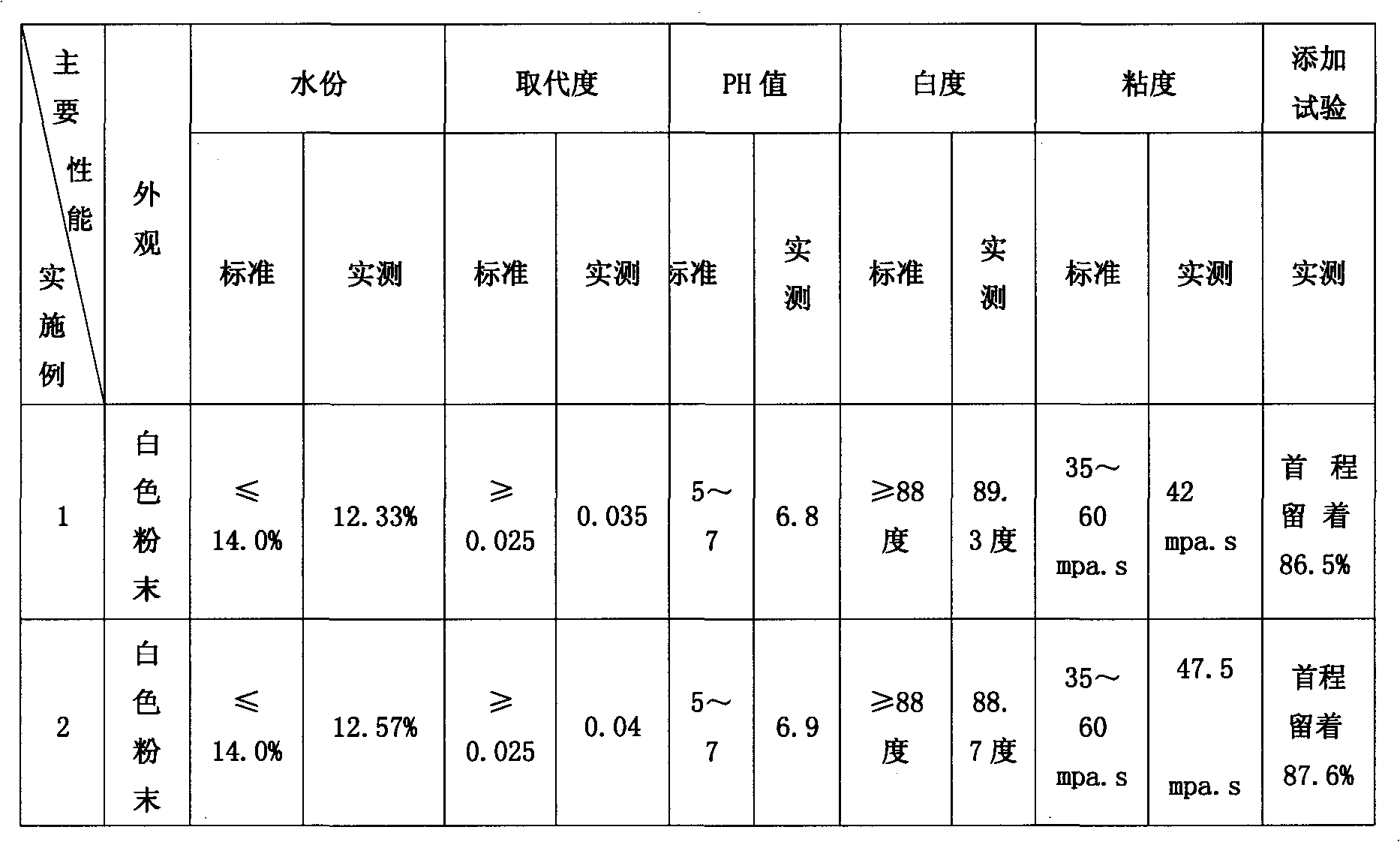

Producing process of quaternary ammonium type cation modifying starch

The invention discloses a producing process of quaternary ammonium type cation modifying starch, comprising the following steps of: mixing, modifying, neutralizing, physically synergizing, screening, weighing and packing. The invention ensures that the common starch has cation characteristics and higher substitution values, reduces pasting temperature and precipitability of starch, has the advantages of reasonable producing process, high heating efficiency, thorough modification, good film forming property, high binding rate, high retention, low cost, small investment, low energy consumption, low pollution, simple producing process, high production efficiency, stable and reliable quality and wide application range and is suitable for large-scale production.

Owner:四川省蓬溪县弘桥实业有限公司

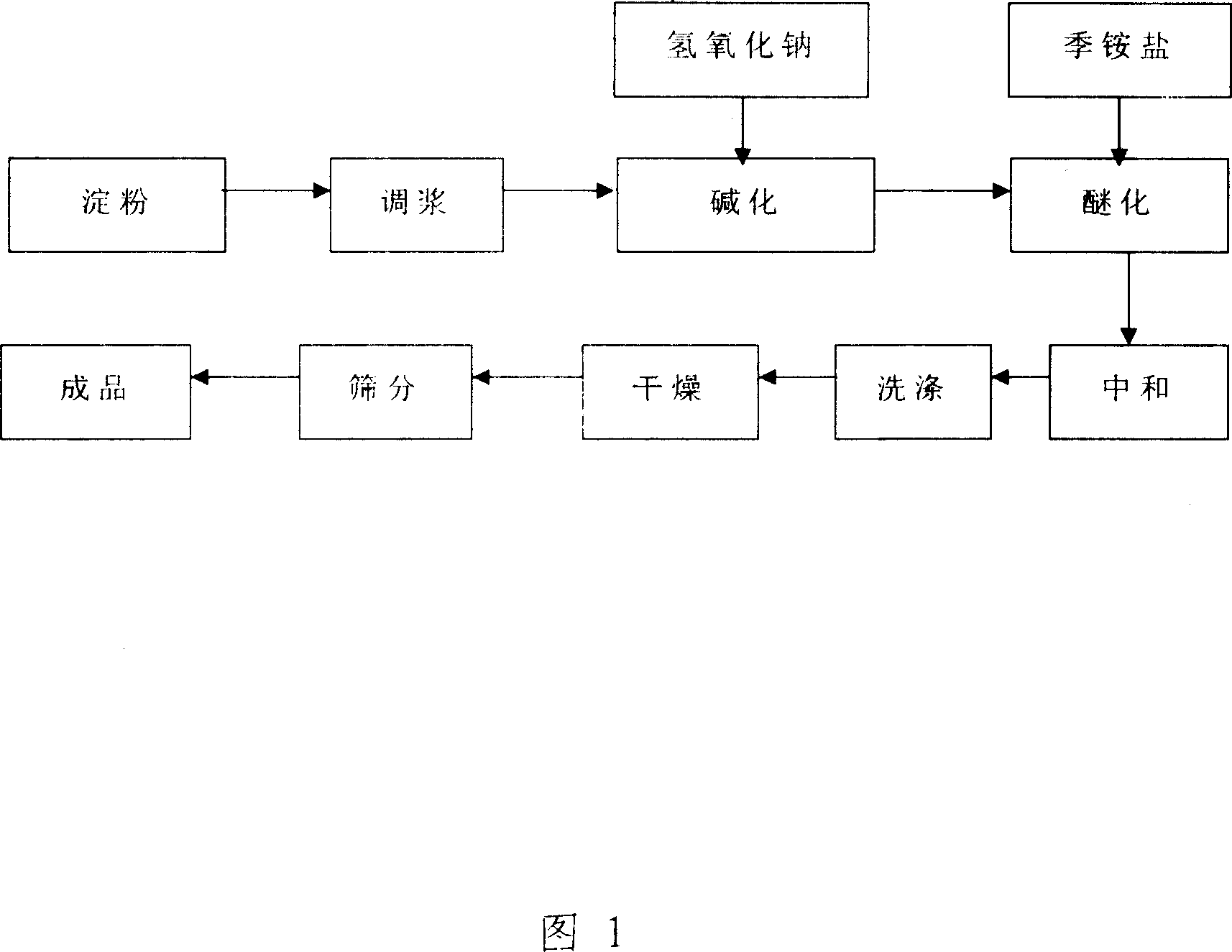

Method of preparing quaternary ammonium type cationic starch

InactiveCN101033260AReasonable production processReduce the temperatureQuaternary ammonium cationSynthesis methods

This invention relates to a synthesis method of quaternary ammonium cationic starch, which takes starch, quaternary ammonium, and sodium hydroxide as raw materials in water medium, and conducts eight steps of conditioning, alkalization, etherification, neutralization, washing, drying, screening, and packaging. The product is white powder, and gels to be the thick translucent gel heated to 50~66deg.C in water with DS values of 0.01 to 0.05. This invention is reasonable, makes the general starch has cationic performance and higher substitution, lowers the gelatinization temperature and freezing, so its effect can completely achieve the requirement of paper industry.

Owner:四平帝达变性淀粉有限公司

Edible fungus beverage

InactiveCN101467780AReasonable production processIncrease nutritional contentFungiFood preparationNutritive valuesBiotechnology

This invention provides a edible fungi drink, which is prepared by inoculating edible fungi to ferment in the culture medium liquid material having main content of potato liquor via the deep fluid fermenting method, separating fermentation liquor so as to acquire a edible fungi mother solution, performing sterilization to the mother solution, adding syrup and water, then uniformly shaking. This drink is prepared by using the biometric method, with short production period, thereby making the drink have high nutritive value. This drink with pure quality, convenience for eating and low cost is good for body health.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Environment protection plastic printing ink and its prepn

The no-benzene green plastic printing ink consists of inorganic pigment or organic pigment, antistatic agent, dispersant, adhesion promoter, alcohol soluble synthetic PVB resin and alcohol solvent. The preparation process includes the following steps: dissolving the alcohol soluble synthetic PVB resin in alcohol solvent to form translucent resin solution; mixing the inorganic pigment or organic pigment with the resin solution to form color slurry semi-product; grinding the color slurry semi-product in a sand mill and adding the other components via stirring; filtering and packing to obtain no-benzene green plastic printing ink product. The no-benzene green plastic printing ink is boiling resistant and freezing resistant and may be used in packing milk, wine, seasoning, aquatic product, medicine, etc.

Owner:TENGXIA PRINT INK ZHUCHENG

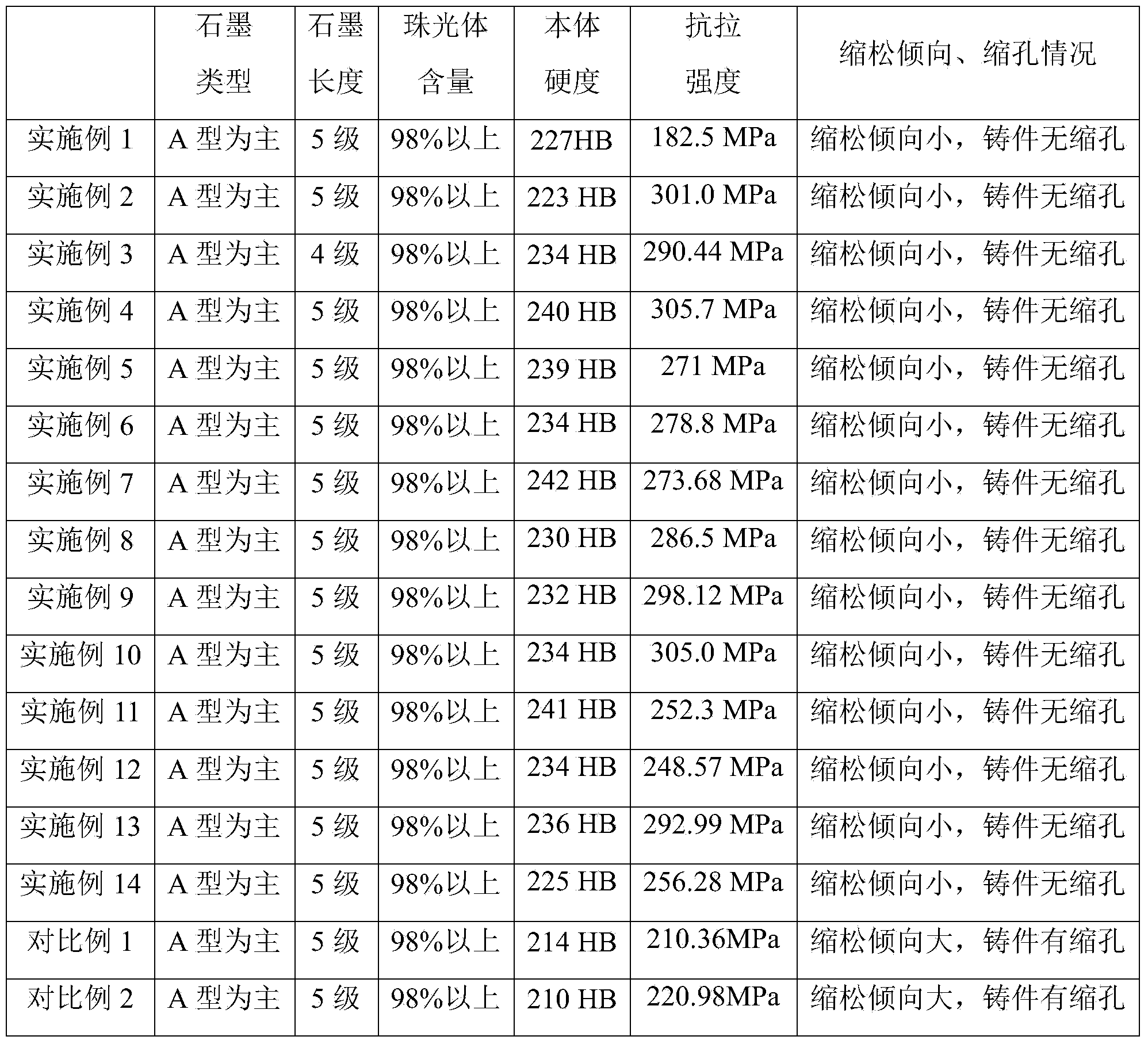

Gray cast iron and production method thereof

The invention discloses a gray cast iron and a production method thereof. The gray cast iron comprises the following chemical components in percentage by weight: 3.1-3.3% of C, 1.8-2.2% of Si, 0.5-0.8% of Mn, 0-0.04% of P, 0.05-0.1% of S, 0.1-0.4% of Cr, 0.3-0.5% of Cu, 0-0.06% of Sn, Sb less than 0.02%, and the balance amount of Fe. The gray cast iron disclosed by the invention is suitable for producing casting parts which easily shrunk, have thick walls, and have marks above HT300; according to the production method of the gray cast iron, the technical means of adding copper, chrome, antimony and tin in molten iron for alloying in the gray cast iron production process is adopted, so that molybdenum and nickel for alloying in the prior art are replaced, thereby solving the problem of high possibility of shrinkage and looseness of gray cast iron products, after the prepared gray cast iron is used for casting and forming, the casting parts have low possibility of shrinkage and looseness, have no shrinkage hole, have high yield and are low in production costs.

Owner:山东海之冠工贸有限公司

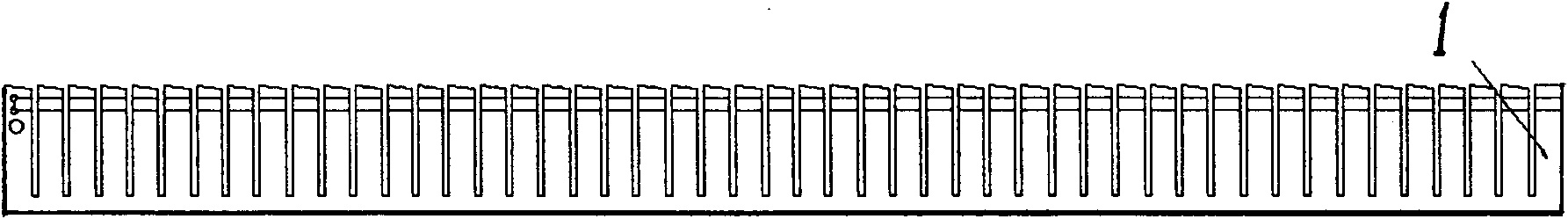

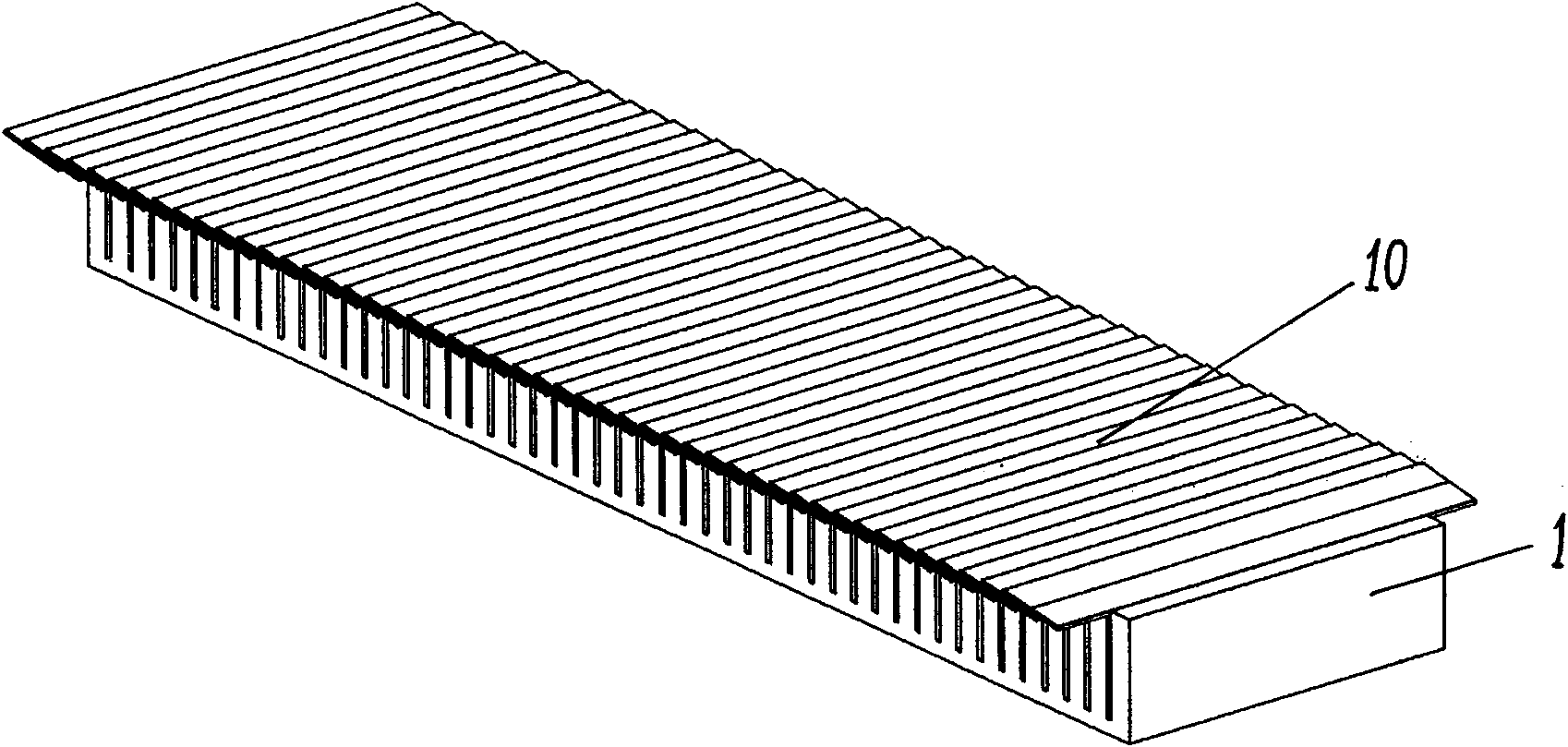

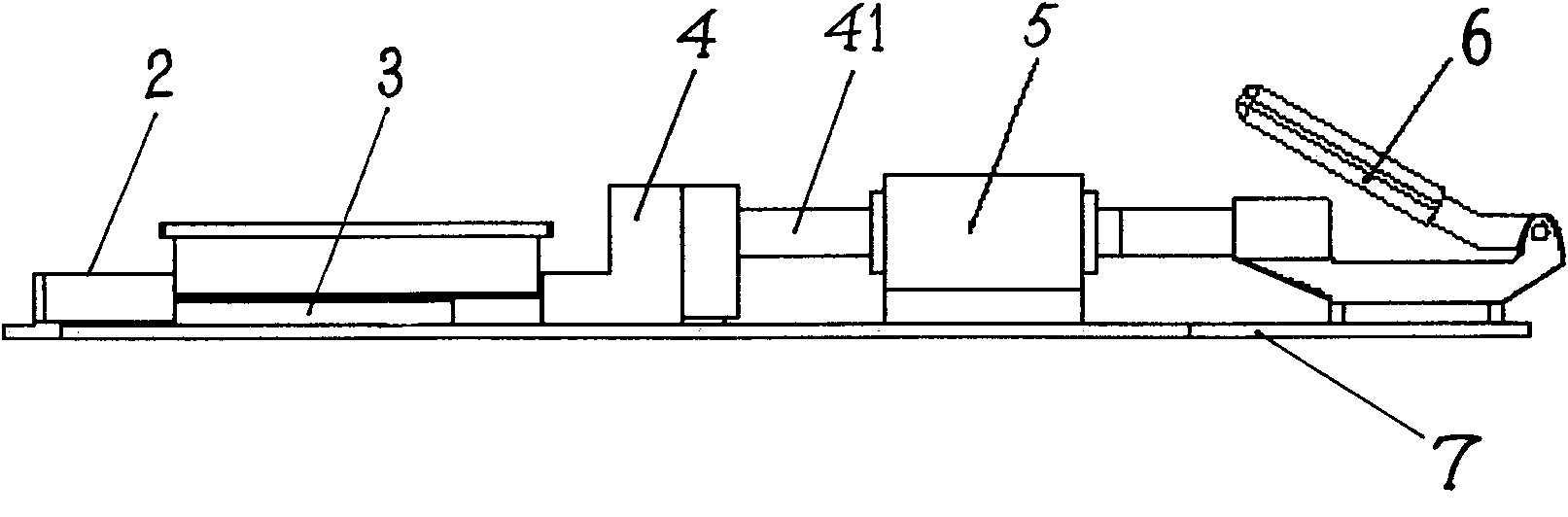

Method and device for collecting fins and arranging and combining fins and flat pipes

ActiveCN101913077AReasonable production processReduce transit proceduresAssembly machinesLean manufacturingMarine engineering

The invention discloses a method for collecting fins and arranging and combining the fins and flat pipes, which comprises the following steps of: (1) finishing equidistant arrangement of the flat pipes by using a pipe-arranging mold; (2) covering a large tray on the arranged flat pipes, turning, and putting the flat pipes into a fin and flat pipe collecting device assembly; (3) pushing a movable block to make the large tray support the flat pipes so as to clamp front ends of the flat pipes in a clamping groove of a guide block, and taking the pipe-arranging mold out; (4) automatically guiding the fins into a guide groove which is composed of the guide block and the flat pipes, and finishing the fin collection and arrangement of the flat pipes; and (5) loosening the movable block, collecting the arranged fins and flat pipes in a small tray or directly assembling the fins and the flat pipes, or stacking and storing the fins and the flat pipes. The invention also provides a corresponding device according to the method, which mainly comprises a pipe-arranging mold, a fin and flat pipe collecting device assembly and a small tray. The method for collecting the fins and arranging and combining the fins and the flat pipes has the advantages of no need of manually collecting the fins, reduction of a transfer program, capacity of preventing adhesion between the fins, automatically arranging the fins and the flat pipes, improving the product quality, along with low equipment investment and contribution to lean production.

Owner:SONGZ AUTOMOBILE AIR CONDITIONING

Shaddock whole fruit beverage and its producing method

The invention relates to a method for preparing beverage with shaddock, comprising following steps: washing shaddock, removing epidermis or not, getting rid of rotten part, separating pulp from peel, washing peel; cutting peel, grinding, controlling temperature and adding proper amount of acid, stirring, adding enzyme to get peel enzyme reacting solution; beating pulp, removing seed and getting pulp slurry, adding proper amount of acid, stirring, adding enzyme to get pulp slurry enzyme reacting solution; mixing peel slurry with pulp slurry enzyme reacting solution, adding gel, sour addictive, sweetener, soluble edible fiber and vitamin C, heating for dissolution, stirring evenly, heating to a certain temperature, loading, sealing, disinfecting, cooling, packing and getting final product. The invention makes full use of whole shaddock, avoids wasting raw material, the production process is reasonable and cost is low and the sour taste of product is proper.

Owner:林伟锋 +3

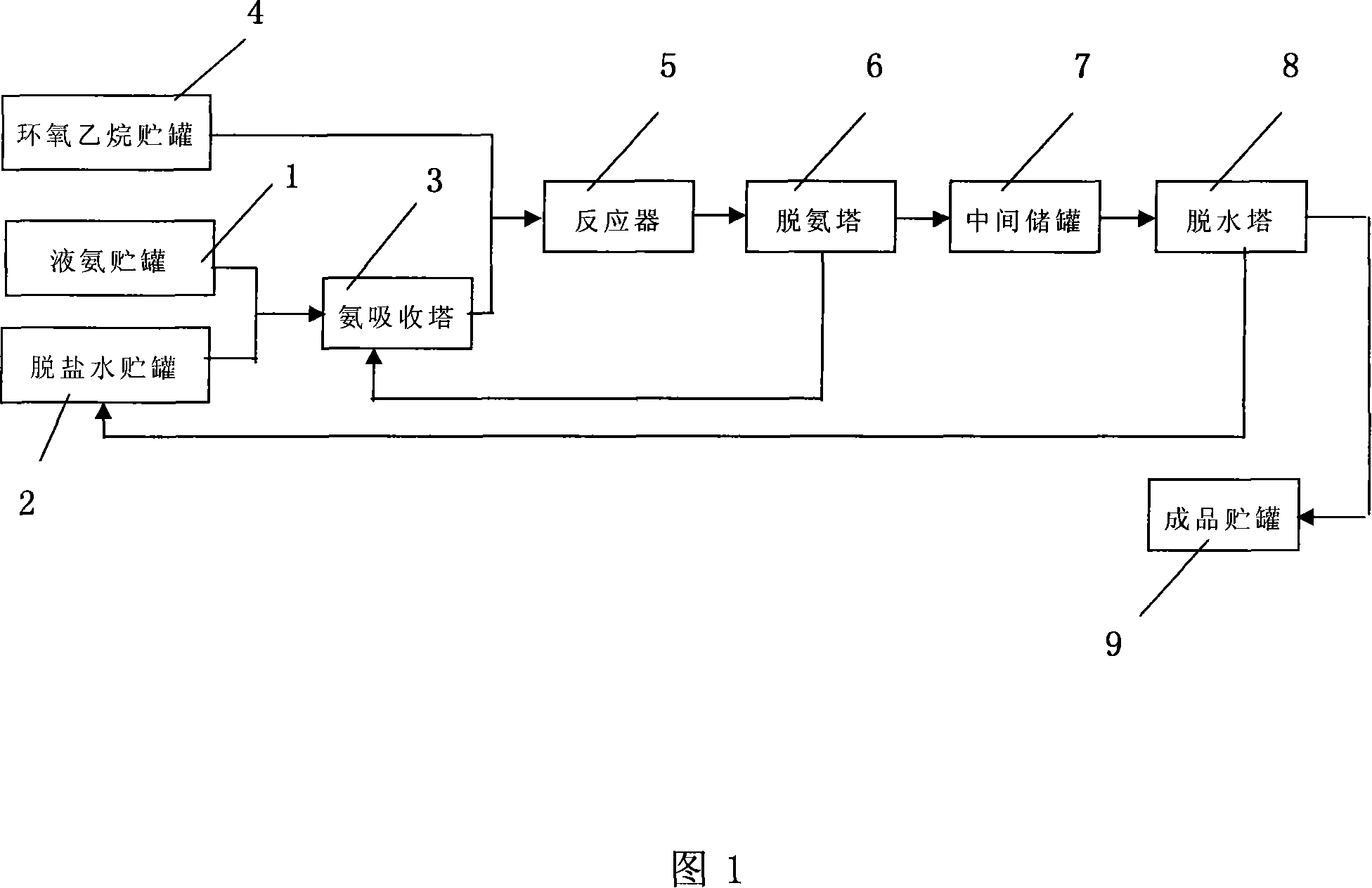

Method for producing pure triethanolamine containing micro-water

InactiveCN101100433AReasonable production processIncrease productivityOrganic compound preparationAmino-hyroxy compound preparationAutomatic controlAmmonium hydroxide

Production of low-purity micro-triethanolamine is carried out by mixing ammonia with ethylene epoxide by mixer, reacting ammonia solution 5-30 wt% with ethylene epoxide in serial tubular reactor in proportion of 0.3-1.0 mol, controlling reactor temperature at inlet and outlet by intermediate cooler, absorbing ammonia, generating ethanolamine, denitrifying and dewatering. Ammonia solution is poured for one time; ethylene epoxide is filled into serial tubular reactor by multi-points. It's efficient, cheap, safe, automatic, stable and rational. It has less consumption and no environmental pollution. It can be used for continuous production.

Owner:LIAONING HUAFENG CHEM INDS GROUP

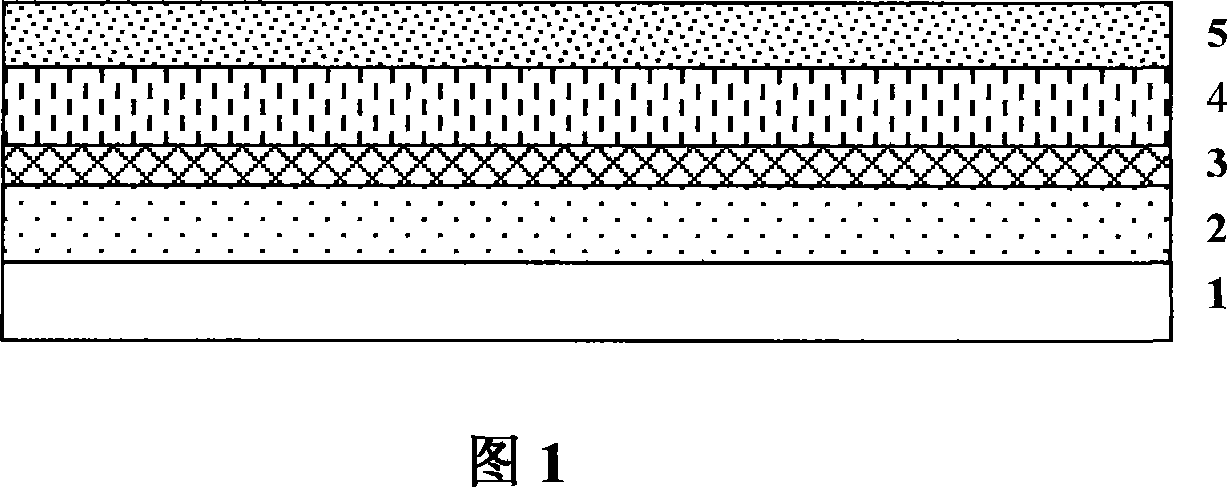

Packing paper with micro-sign for cigarette and producing method thereof

ActiveCN101168943AImprove identification rateBright metal textureSpecial visual effect coatingsFlexible coversCigarette usePulp and paper industry

The invention relates to cigarette packing tipping paper, in particular to a production method of a cigarette-purpose tippling paper with a laser microfilm anti-counterfeit sign. The tipping paper comprises a bottom layer, a binding layer, an aluminum coating, a surface coating and a printing layer which are mutually compounded in sequence, wherein, a microfilm anti-counterfeit sign composed of a microfilm character or a RMB paper money line is arranged on a surface coating, and the size of the microfilm anti-counterfeit sign can reach 0.2 mm. The invention has the production method of the cigarette-purpose tipping paper with the microfilm anti-counterfeit sign that a strippable surface coating is coated on a high molecule light film in advance, and then the laser microfilm anti-counterfeit sign which forms an aluminum transferring film after vacuum aluminum coat is molded and is compounded with the original paper, then various patterns are printed after uncovering the light film, and therefore the cigarette-used tippling paper with the laser microfilm anti-counterfeit sign can be obtained. The product of the invention has nicer anti counterfeit performance.

Owner:JIANGSU DAYA NEW PACKAGING MATERIALS

Production process of glazed devitrified glass tile

InactiveCN1417166AImprove purification effectUse less clayClaywaresHigh wear resistanceTechnological design

The production process of devitrified glass glazed tile includes the preparation of devitrified glass glaze and the production of tile body. The present invention is characterized by the devitrified glass glaze comprising SiO2, CaO, Al2O3, MgO, Na2O, TiO2, Fe2O3 and BaO; and the tile body raw material includes waste glass, sandstone, clay and binder. Compared with prior art, the present inventionhas reasonable technological design, available raw material, waste utilization, low cost, high wear resistance, fine texture, high pollution resistance, natural beauty similar to natural granite and excellent characteristic.

Owner:UNIV OF JINAN

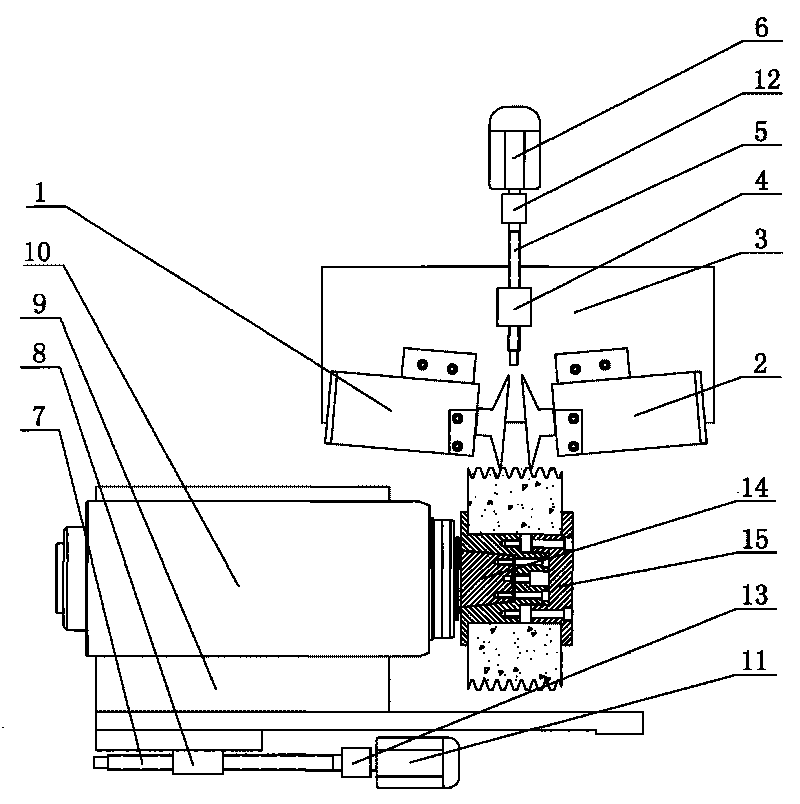

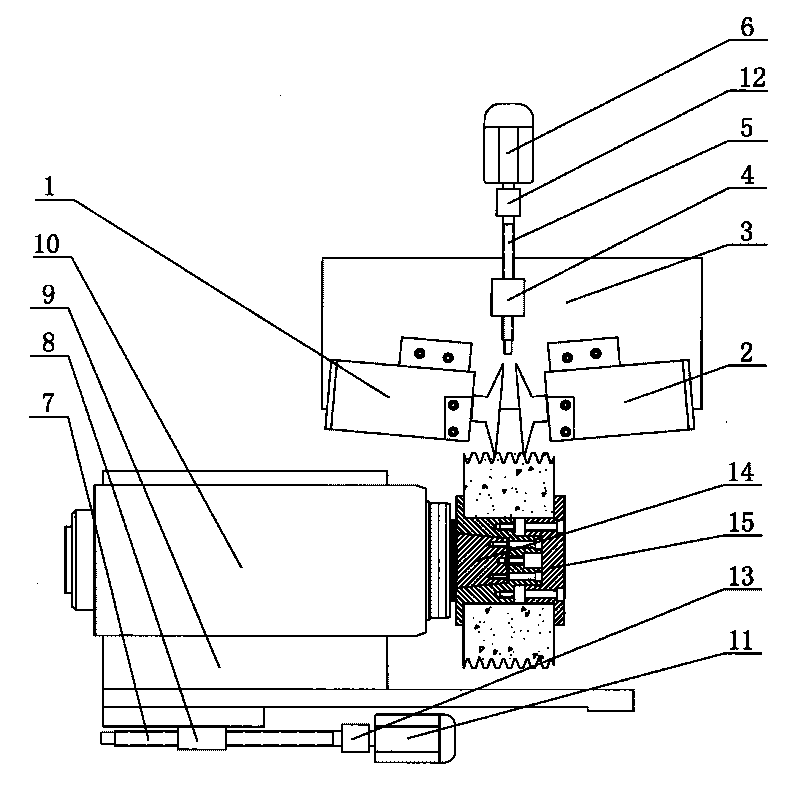

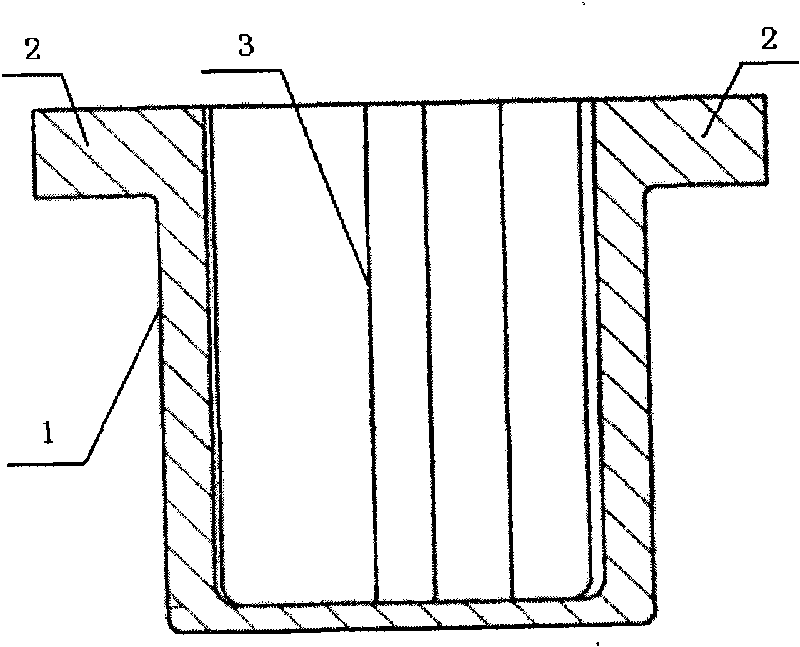

Grinding wheel finishing mechanism of gear grinding machine with worm grinding wheel

InactiveCN101758303AReasonable structureReasonable production processAbrasive surface conditioning devicesGear-cutting machinesElectric machineryEngineering

The invention discloses a grinding wheel finishing mechanism of gear grinding machine with worm grinding wheel, which includes a bracket I, a sand wheel finisher I, a sand wheel finisher II, a screw I, and a screw II; the bracket I is provided with the sand wheel finisher I, and the sand wheel finisher II with adjustable angles; the bracket I is connected with the screw I through a screw assembly I; one end of the screw I is connected with the power output shaft of a motor I; one end of the screw II is connected with the power output shaft of a motor II; the screw II is provided with a screw assembly II; the screw assembly II is fixedly arranged on a bracket II; the bracket II is provided with a motor III; and the power output shaft of the motor III is connected with a worm grinding wheel waiting for finishing. The grinding wheel finishing mechanism of gear grinding machine with worm grinding wheel has the following characteristics of rational structure, simple manufacturing process, double-shaft interlocking, good processing effect, high processing efficiency, adjustable working angle of sand wheel finishers, and low production cost.

Owner:西安贝吉姆机床股份有限公司

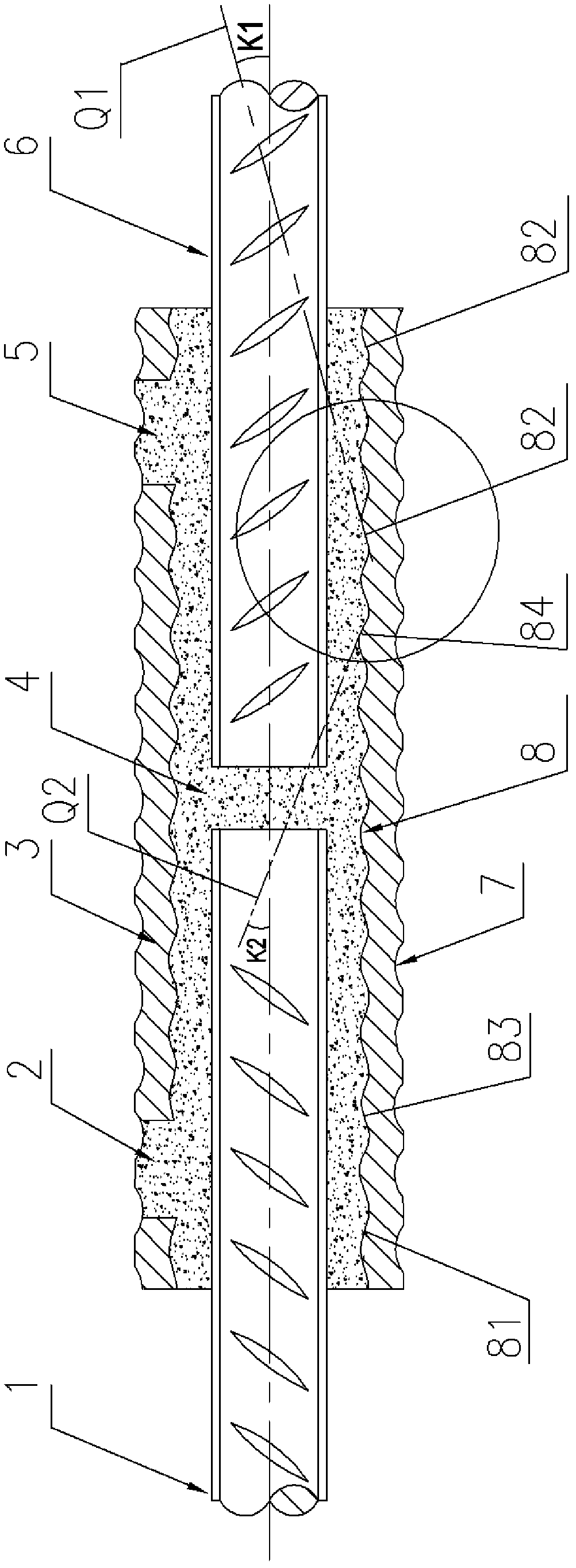

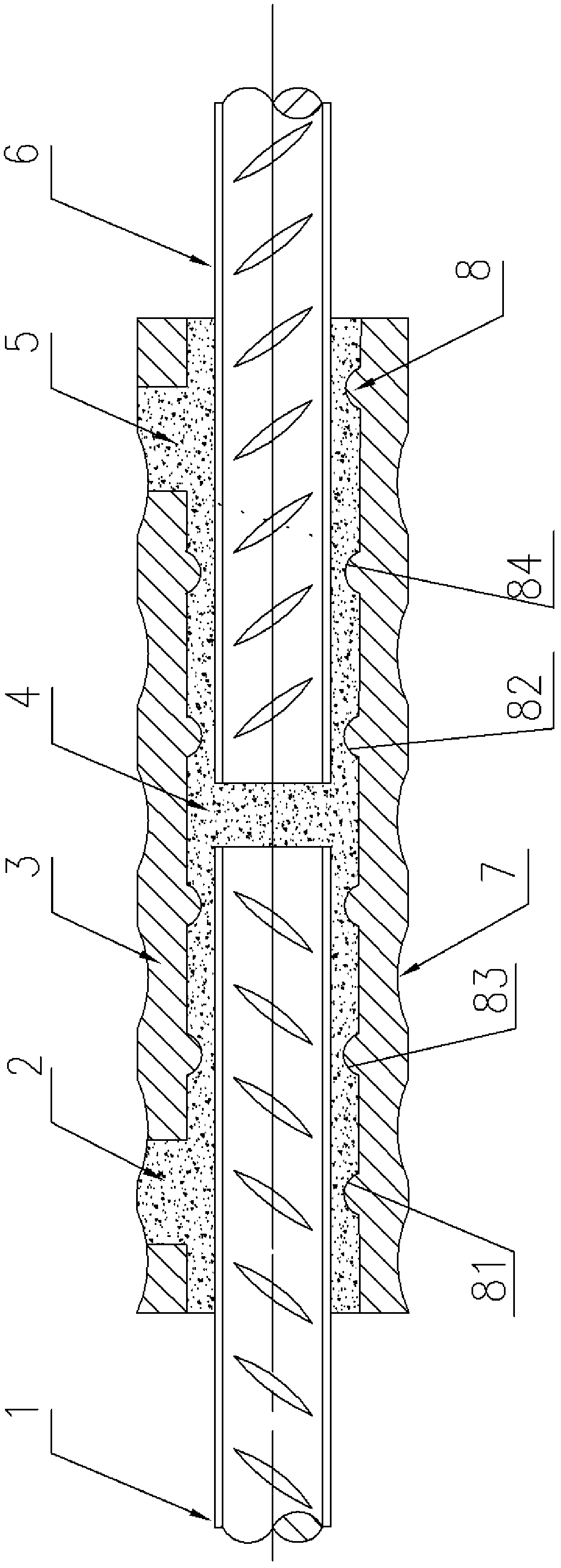

Cement grouting reinforcement connector

InactiveCN102828580AImprove mechanical performanceIncreased durabilityBuilding reinforcementsCement groutRebar

A cement grouting reinforcement connector comprises connecting reinforcements, a connecting sleeve and cement mortar; and the abutted ends of the two connecting reinforcements are combined into a connection body by the connecting sleeve and hardened cement mortar full of the gap of the connecting sleeve. The outer surface of the connecting sleeve and the inner wall of the sleeve are respectively provided with continuous or discontinuous grooves or bosses. The connector has the following advantages that a seamless steel pipe, a forged steel cylinder or a stamped steel cylinder which has high strength and stable property is used as the connecting sleeve, and the grooves in the outer surface of the connecting sleeve and the bosses on the wall of the inner holes are formed by using a rolling-pressing or rotary-pressing method. The raw material dosage is greatly reduced by the improvements of the structure and the material of the sleeve; and the cutting processing amount is greatly reduced by the improvement of the machining technique of the sleeve, and therefore, the cost of the sleeve is reduced and the production efficiency is increased; and the economic and technical indexes of the connector exceed those of the known cement grouting reinforcement connectors.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

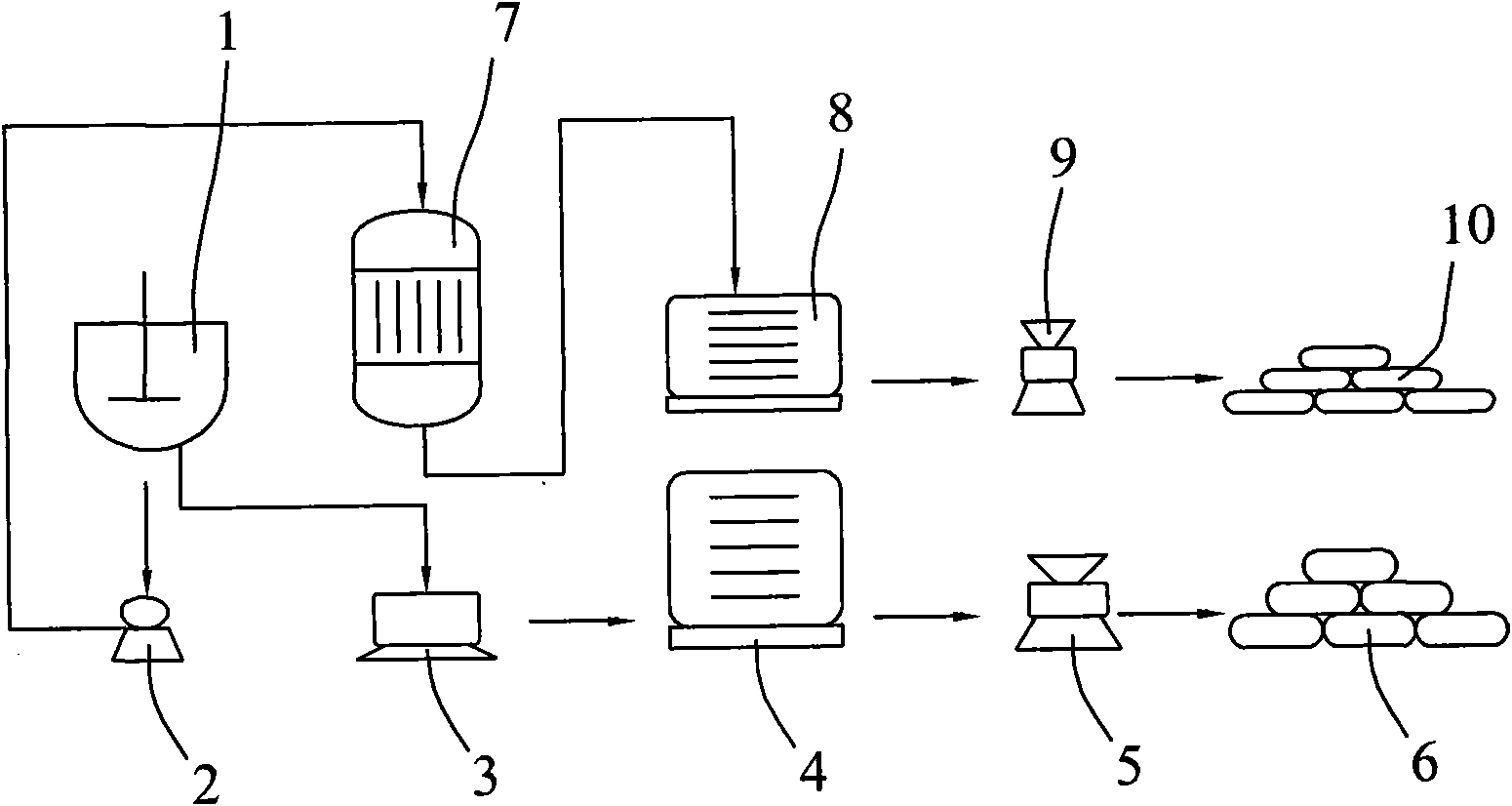

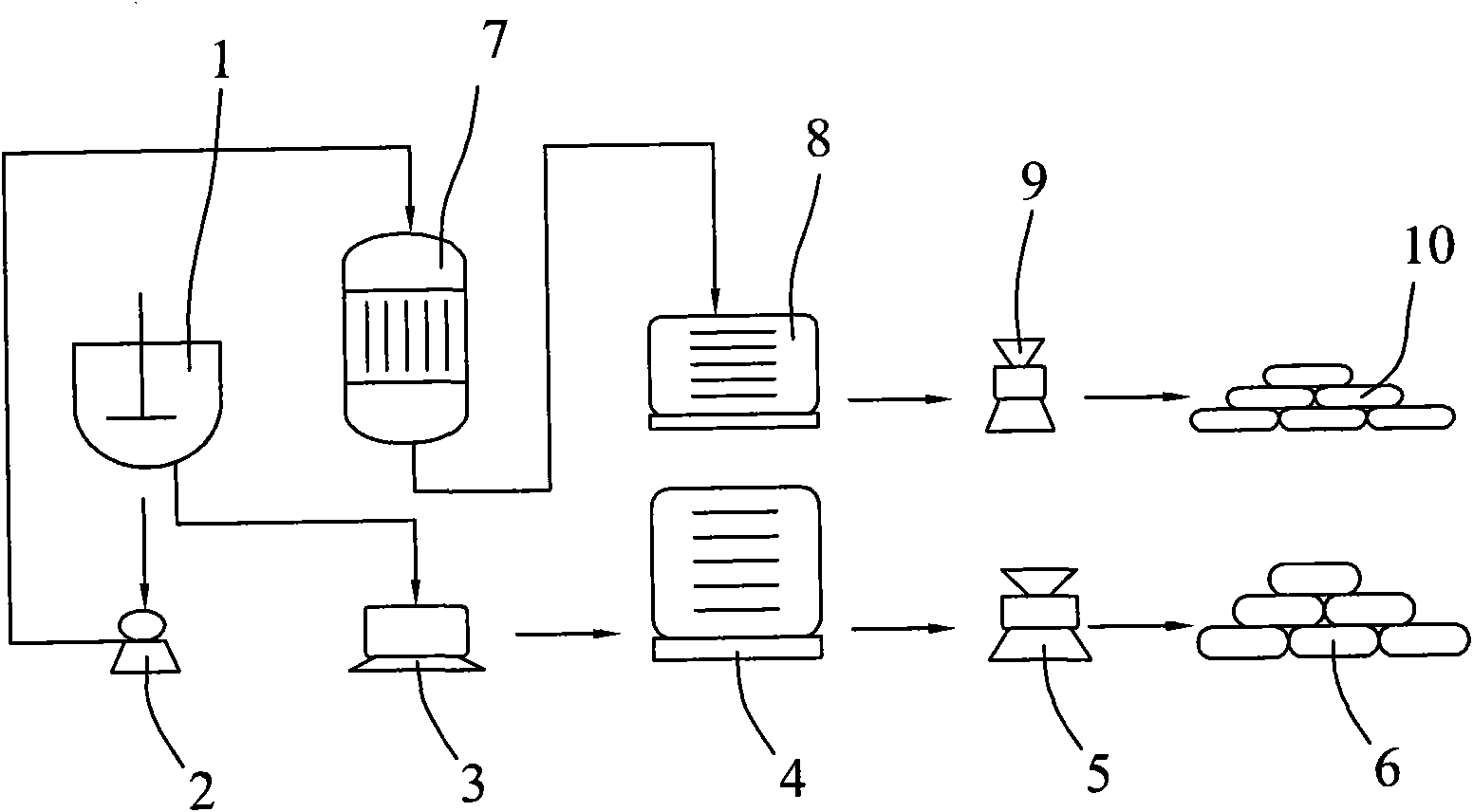

Method for preparing calcium carbonate and co-producing sodium sulfate by using phosphorus gypsum and soda ash

InactiveCN101850992AReasonable production processSimple production equipmentCalcium/strontium/barium carbonatesSulfate/bisulfate preparationChemical reactionDistillation

The invention discloses a method for preparing calcium carbonate and co-producing sodium sulfate by using phosphorus gypsum and soda ash. The method comprises the following steps of: (1) calculating pure calcium sulfate substance content of a phosphorus gypsum product, feeding the phosphorus gypsum and sodium carbonate solution into a reactor in a mass ratio of pure substances of the calcium sulfate and the sodium carbonate of 1: 0.58-0.78, and performing chemical reaction with slow stirring; (2) filtering a reaction product obtained in the step (1) in a filter to obtain clear sodium sulfate solution and calcium carbonate filter cakes; (3) washing the calcium carbonate filter cakes obtained in the step (2) by using water, centrifuging the solution through a centrifuge, separating solid and liquid, drying the solid through a dryer, and crushing the solid through a first crusher to obtain a calcium carbonate product; and (4) conveying the sodium sulfate solution obtained in the step (2) into a reduced pressure distiller to perform reduced pressure distillation, then cooling a reduced pressure distillation product in a cooler, and crushing the reduced pressure distillation product in a second crusher to obtain a powdery sodium sulfate product.

Owner:汪晋强

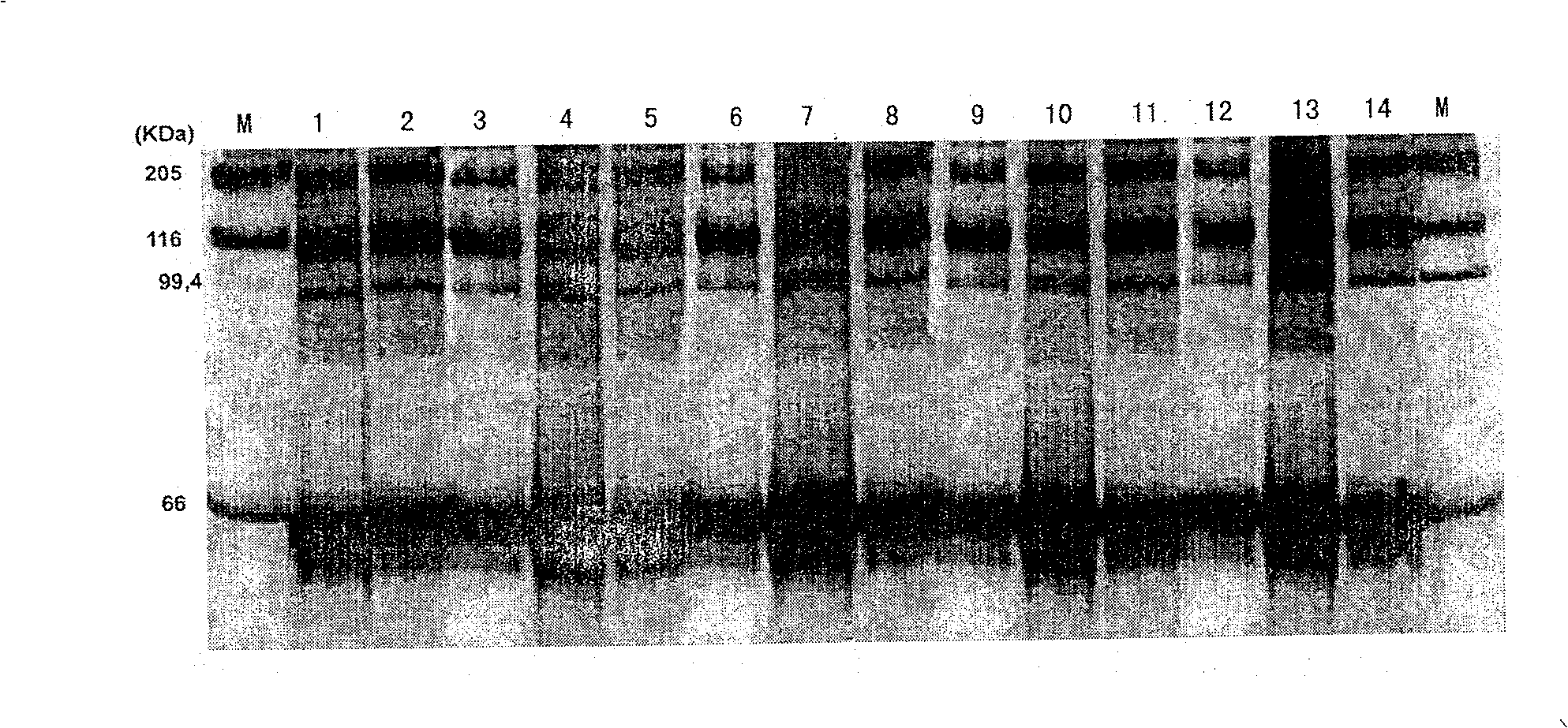

Method for extracting rabies virus

InactiveCN101270350AImprove removal efficiencyGood removal effectSsRNA viruses negative-senseMicroorganism based processesHollow fibreFiber

The invention provides a method for extracting rabies virus, and is to solve the defects that great discrepancy of quality indices of different batches occurs; removal of remaining DNA becomes difficult; the protein content of the remaining host is too high; and great side effects appear clinically when the single method of molecular sieve gel chromatography is adopted for extracting rabies virus vaccine. The essential of the invention is that a hollow fiber ultrafiltration column or ultrafiltration membrane with the molecular weight cut-off of 750KD or 500KD is used to condense and partially purify harvested liquid of virus; anion exchange chromatography or molecular sieve gel chromatography is adopted to separate and purify samples; molecular sieve gel chromatography or anion exchange chromatography is adopted to separate and purify samples got in step (2). The method for extracting rabies virus has the characteristics of great productive capacity, high product quality, excellent batch stability, being remarkably effective in removal of remaining DNA and HCP, and reducing the potential safety hazard of vaccine.

Owner:LIAONING YISHENG BIOLOGY PHARMACY

Method for preparing hot melt adhesive

InactiveCN102653666ASuitable for production process requirementsReasonable formula designMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a method for preparing hot melt adhesive. The method comprises the steps of: mixing EVA (ethylene-vinyl acetate), a tackifier and a diluent according to parts by weight, and then heating, stirring, smelting and cooling the mixture. The hot melt adhesive comprises 5-10 parts of EVA, 2-6 parts of a tackifier, 5-10 parts of a diluent, 0.5-1.5 parts of an antioxidant and 0.5-1.5 parts of a plasticizer; the tackifier is one of abietic resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent is one or two of wax and micro-molecular polyolefin; and the antioxidant is a phenolic antioxidant; and the plasticizer is DCHP (dicyclohexylphthalate). The stirring speed is 200-750 rpm; the heating temperature is 200-400 DEG C; and the cooling temperature is 10-25 DEG C.

Owner:成都鑫三洋科技发展有限公司

Water-saving medicine slag film coating base fertilizer and producing method thereof

InactiveCN101165014ASlow release fertilizerMeet the needs of the growth periodClimate change adaptationBioloigcal waste fertilisersSlagAdhesive

The present invention discloses one kind of water-saving medicine dreg coating base fertilizer and its production process, and belongs to the field of agricultural chemistry. The water-saving medicine dreg coating base fertilizer is made with composite fertilizer and coating agent, and the materials include fermented liquid after producing cefo medicine, lignin powder, adhesive, talcum powder and stabilizer. It consists of nitrogen fertilizer, phosphate fertilizer and potash fertilizer, medium and trace element fertilizer and aminated humic acid powder. The present invention is environment friendly, and the production process is simple and suitable for industrial production.

Owner:菏泽开发区曹州农用化学有限公司

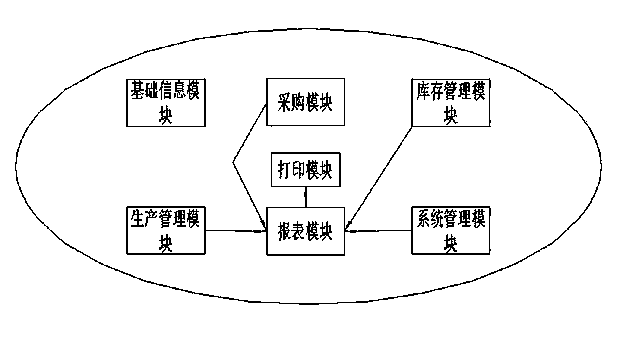

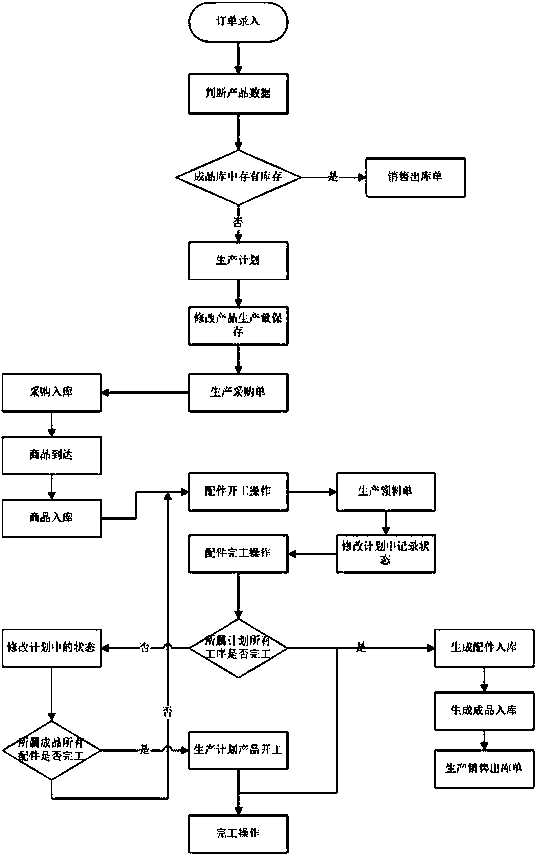

Production management system

InactiveCN103514507AReasonable production processIncrease productivityResourcesApplication serverSystems management

A production management system is characterized by comprising a client side, a data base side and an application server side, wherein the client side is connected with the application server side which is connected with the data base side; the client side is composed of a basic information module, a purchasing module, an inventory management module, a production management module, a statement module, a system management module and a printing module, and data of all the modules are mutually associated. Due to the fact that all links in a production process are accurately arranged, the production process is more reasonable, production efficiency is improved, waste in the production process is reduced, and benefits are improved.

Owner:LUOYANG WOKE NETWORK TECH

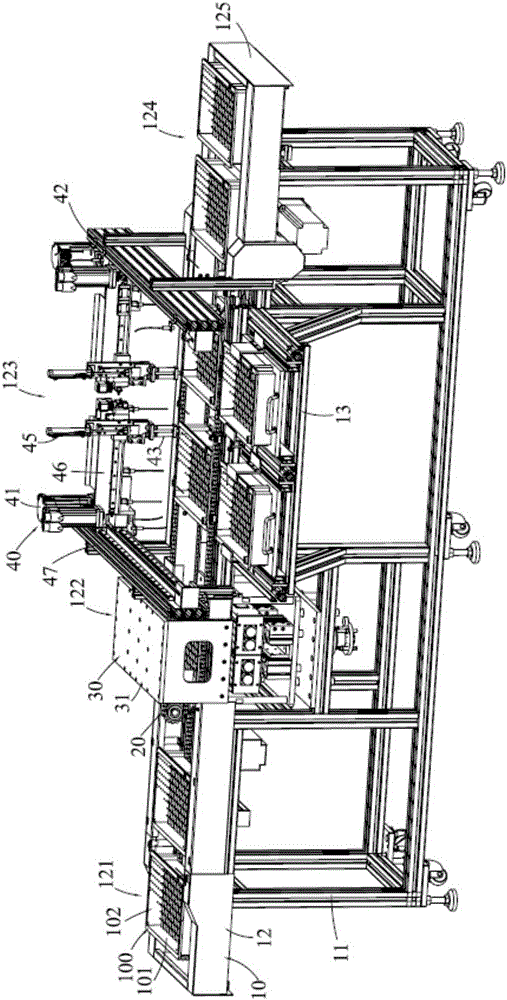

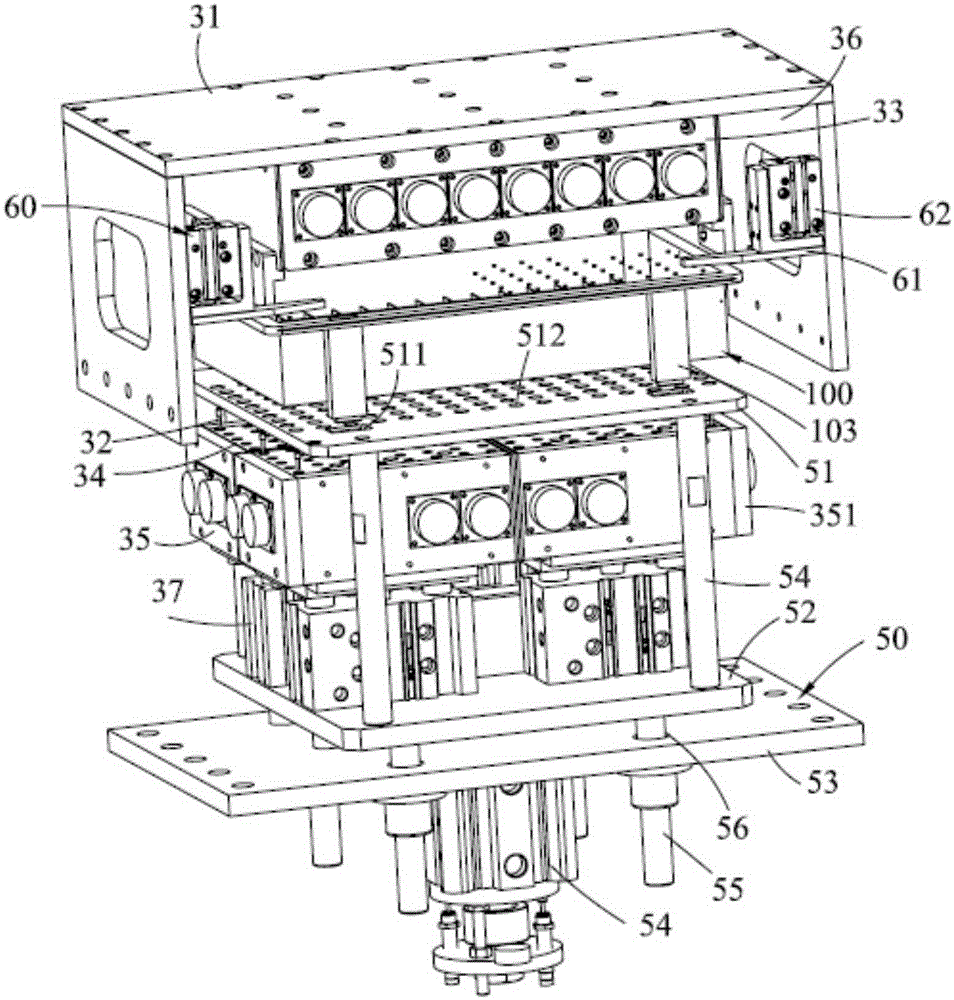

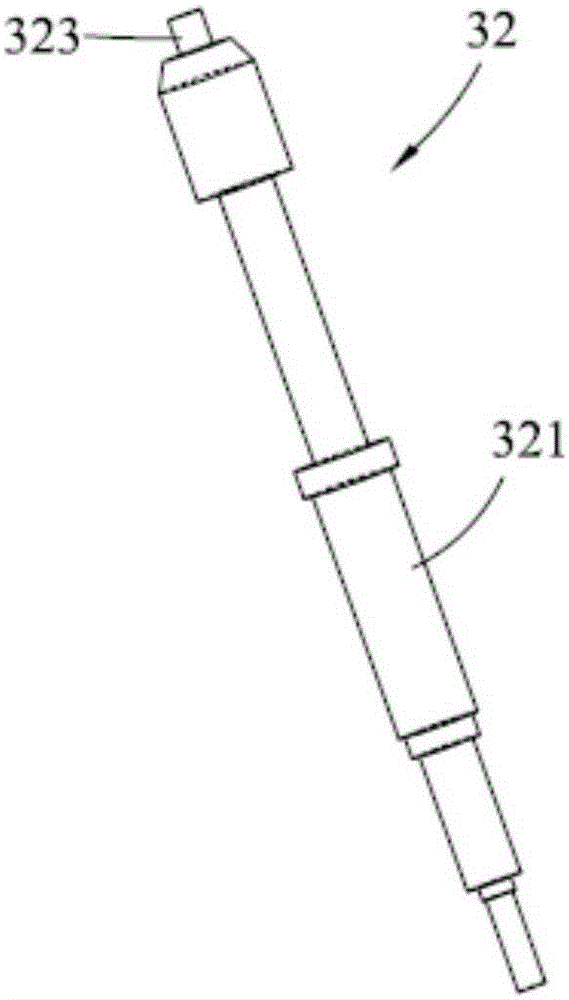

Battery detection apparatus and battery detection technology

InactiveCN105182242ARealize automated detectionReasonable production processElectrical testingSortingElectricityControl system

The invention relates to a battery detection apparatus used for detecting batteries in material boxes. The battery detection apparatus includes a frame body as well as a transmission device, a detection system and a material feeding and compensating system which are arranged on the frame body and a control system for controlling the transmission device, the detection system and the material feeding and compensating system; the material boxes are arranged on the transmission device and pass through the detection system and the material feeding and compensating system sequentially through the transmission of the transmission device; the detection system includes first probes and second probes which are arranged at two opposite sides of the transmission device, and a lifting device which drives the first probes and / or the second probes to move so as to make the first probes and the second probes to electrically contact with the batteries; the material feeding and compensating system comprises mechanical arms; when the first probes and the second probes electrically contact with the batteries, the control system analyzes the parameters of each battery and obtain analysis conditions; the control system controls the mechanical arms to remove batteries which do not accord with a parameter range from the material boxes according to the analysis conditions, and further controls the mechanical arms to move batteries which accord with the parameter range into the material boxes, so that vacancies in the material boxes can be filled.

Owner:苏州大源自动化科技股份有限公司

Synthetic method for N(2)-L-alanyl-L-glutamine dipeptide

InactiveCN1683391AEasy to separate and purifyThe synthesis process is simpleDipeptidesL-alanyl-l-glutamineDipeptide

The present invention relates to synthesis of dipeptide containing amino acid, and provides a kind of synthesis process of N(2)-L-alanyl-L-glutamine dipeptide with low material cost, simplicity, high yield, no need of separating and purifying intermediate product, easy product separation and purification and environment friendship. The synthesis process includes the reaction of amino acid with protected N-terminal with phosphorus triphenyl oxide and triphosgene in organic solvent to form active ester; the reaction of the active ester with glutamine in water solution of inorganic alkali; acidifying with inorganic acid and eliminating N-terminal protecting radical.

Owner:XIAMEN UNIV

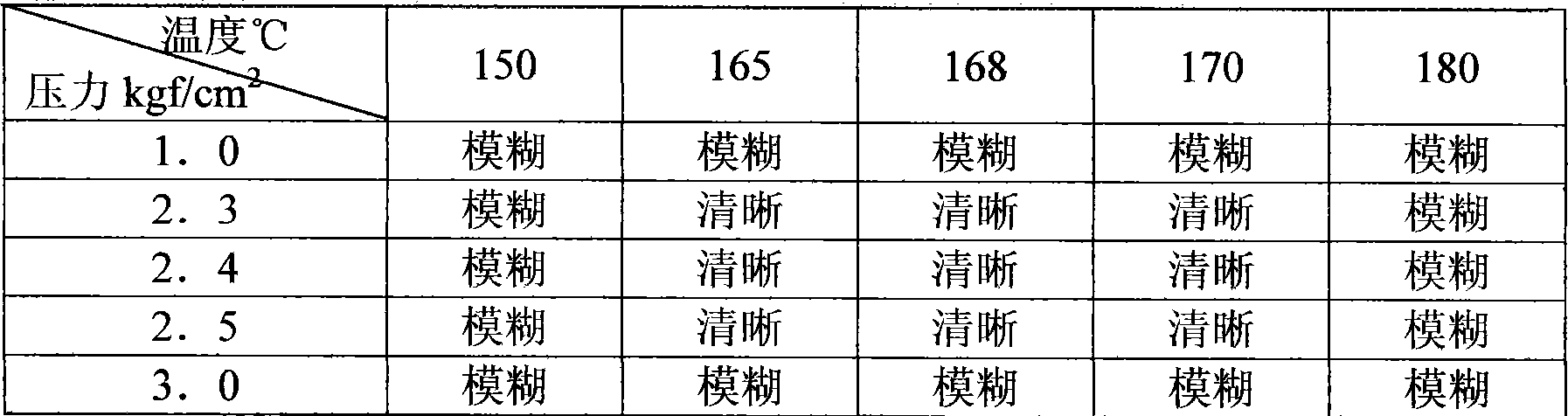

Production method of embossing form packing paper

InactiveCN101205695AStrong metal textureGood flexibilityFlexible coversMechanical working/deformationSurface layerPaper production

An embossing type tipping paper production method relates to the packaging material technical field. The invention comprises the following procedures that: a. coating: PET plastic light film is adopted as base material; a layer of macromolecule resin material is uniformly coated on the base material in advance; after drying and solidification, a layer of transparent surface coat with strippable performance is formed; b. mould pressing: after the coating, under the conditions of the pressure of 2Kg / cm<2> to 4Kg / cm<2>, the temperature of 160 to 180 DEG C and the speed of 35 to 45 m / min, characters or patterns on a mould pressing plate are transferred on the transparent surface coat of the PET plastic light film; a printing layer stuck on the transparent surface coat is produced to form a surface layer; c. aluminium plating; d. transferring; e. embossing: aluminum transferring paper achieved by the procedures is sleeved between a reverse rotating knaggy patterned roller and an elastic roller which are tangential. The invention has good anti-fake effect and suboptical effect and is easy to mass production.

Owner:DARE TECH

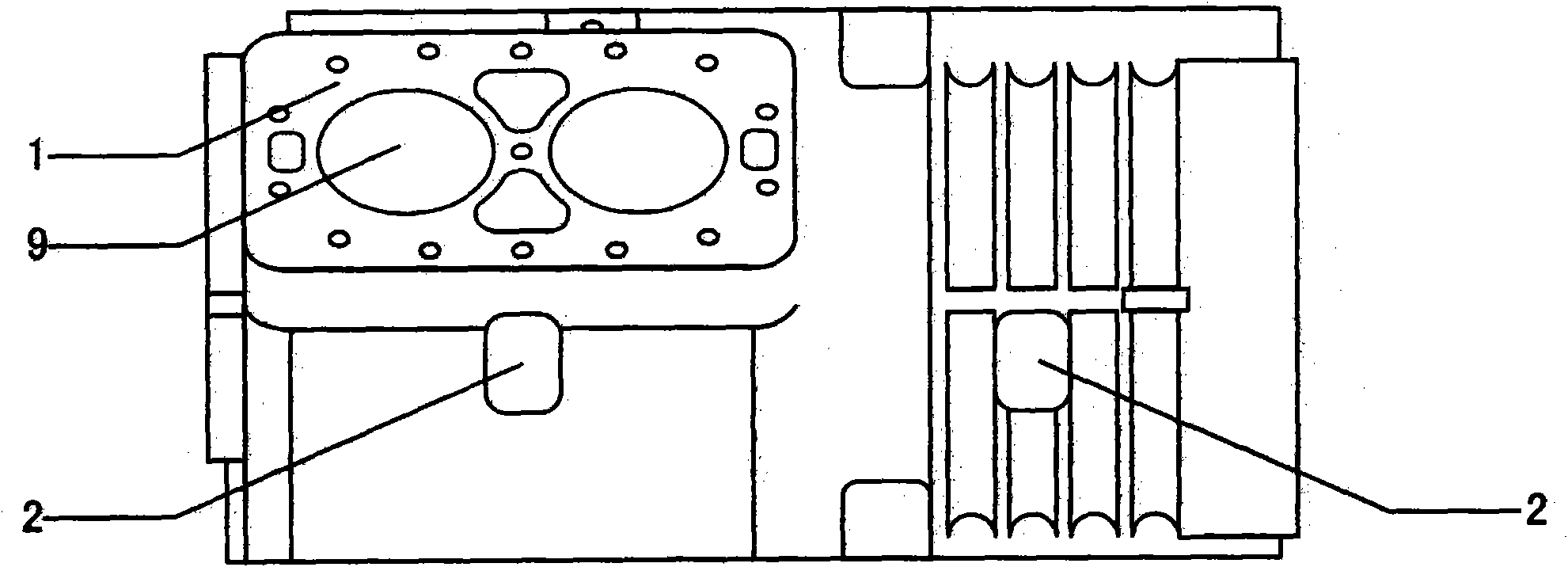

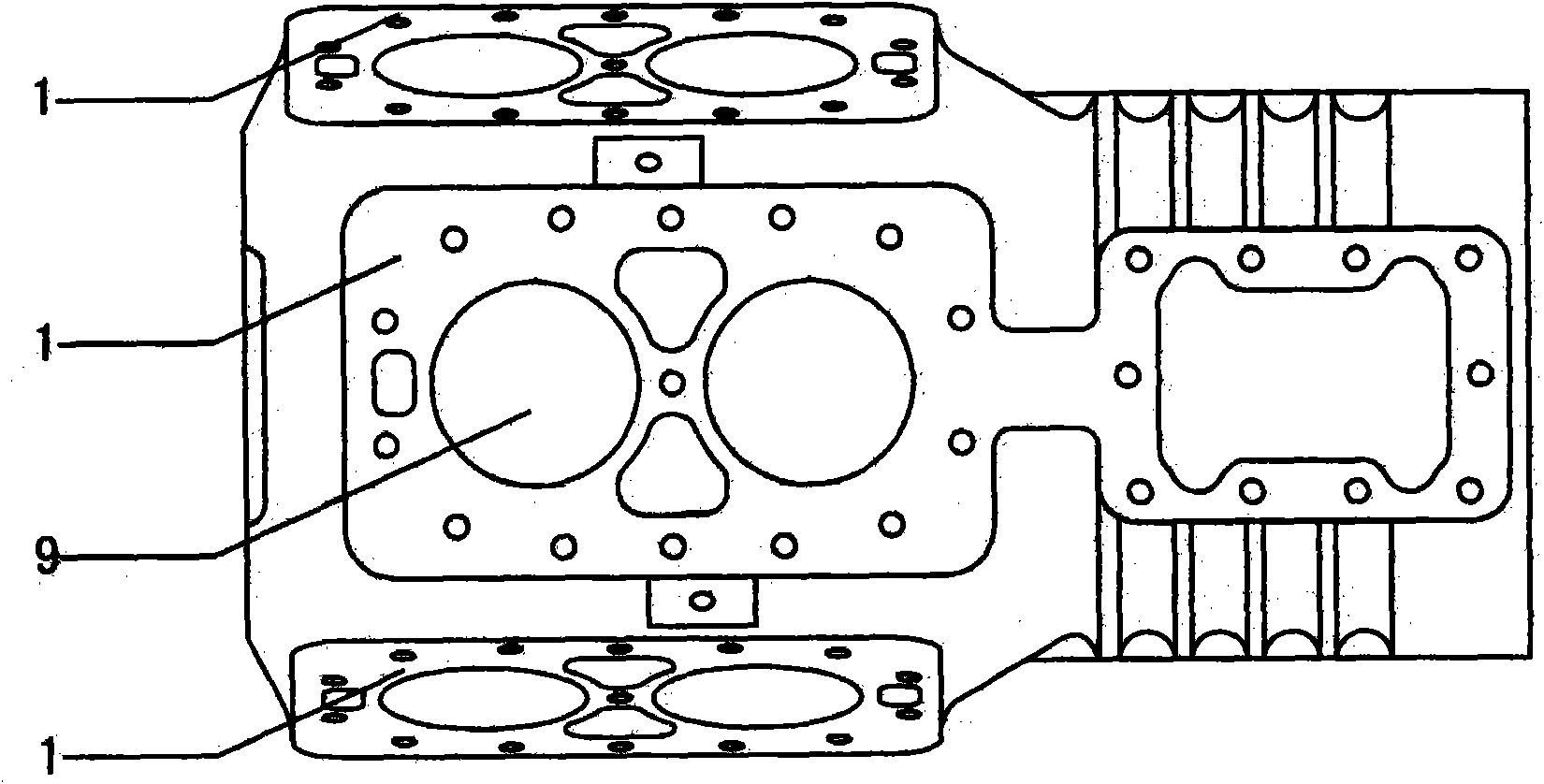

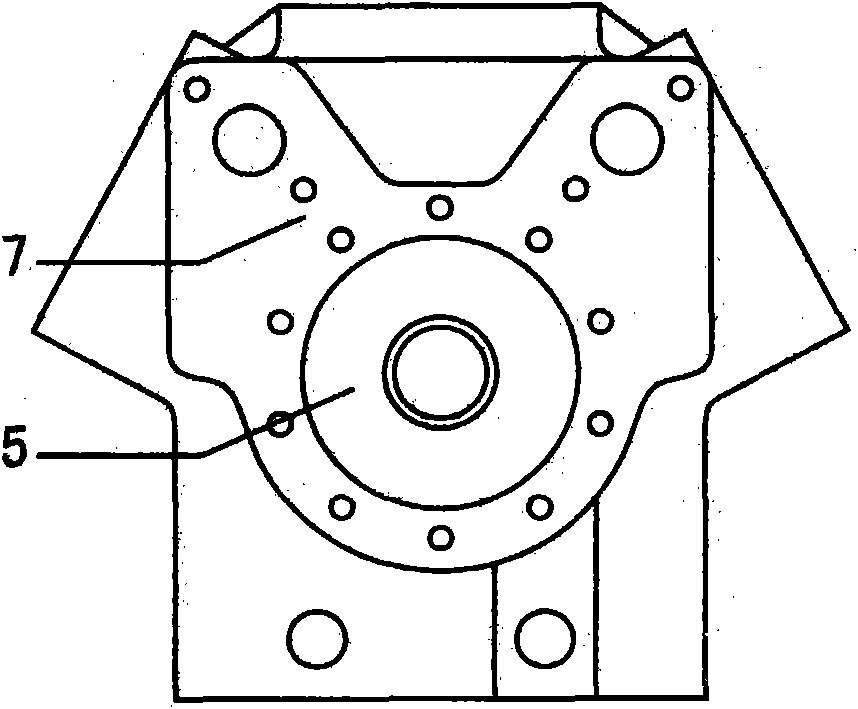

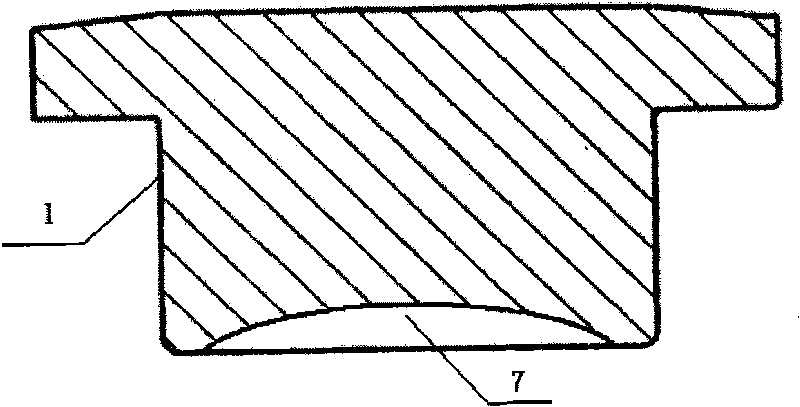

Manufacturing method of large-scale reciprocating type refrigeration compressor

The invention discloses a manufacturing method of a large-scale reciprocating type refrigeration compressor, which mainly comprises the following steps of: (1) sorting: selecting appropriate casting iron; (2) casting; (3) milling and rough machining an upper face and a lower face; (4) rough machining three holes and the faces; (5) milling and fine machining the upper face and the lower face; (6) fine machining the three holes and the faces; (7) boring an air cylinder hole; (8) drilling and tapping a cylinder body face, an end cover face and a motor cavity face; (9) honing the surface of the air cylinder hole; (10) plasma quenching the surface of the air cylinder hole; and (11) honing the surface of the air cylinder hole again. The manufacturing method of the large-scale reciprocating type refrigeration compressor has the advantages that the accuracy of a product can be effectively improved; and the hardness of the surface of the air cylinder hole of the product can be improved in a double mode.

Owner:李永达

Production technology for blanking by using a through-hole type universal joint finish forging pot shell capable of moving axially

ActiveCN101733350ASolve unreasonable phenomenaReasonable production processYielding couplingForging/hammering/pressing machinesMaximum diameterUniversal joint

The invention discloses a production technology for blanking by using a through-hole type universal joint forging pot shell capable of moving axially. The production technology comprises the following steps: blanking, heating, performing local upsetting and extruding in a blanking impression to form a pole part and a blank disk part, wherein the pole part is composed of cylindrical entity parts with different diameters and transition parts thereof, each transition part is an entity part formed by rounds with gradually increased diameter or gradually decreased diameter, and the difference between the product of the maximum diameter of the pole part and the overall length of the pole part and the volume of the pole part is less than the volume of the inner hole which is formed through the backward extrusion of a flange part; then placing the blank in a finishing impression, performing backward extrusion on the blank disk part to form an inner hole ball path in the centre of the blank, perform extrusion molding on the blank disk part to form the flange part of the product, sawing the bottom and dressing. The invention mainly solves the technical problem that the proportion of technical excess material is larger in the existing forging technology, saves raw materials and reduces the production cost.

Owner:江苏威鹰机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com