Method and device for collecting fins and arranging and combining fins and flat pipes

A technology of arrangement and collection device, which is applied in the field of production device, fin collection and arrangement and combination of flat tubes, can solve the problems of multi-capital investment of tube arrangement equipment, affect assembly speed, affect performance, etc., to save equipment import costs, The effect of reducing transfer procedures and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the device for fin collection and arrangement and combination with flat tubes of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following implementation.

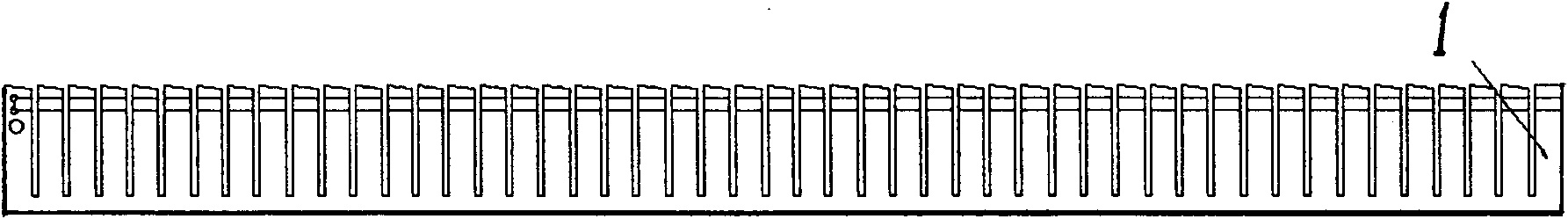

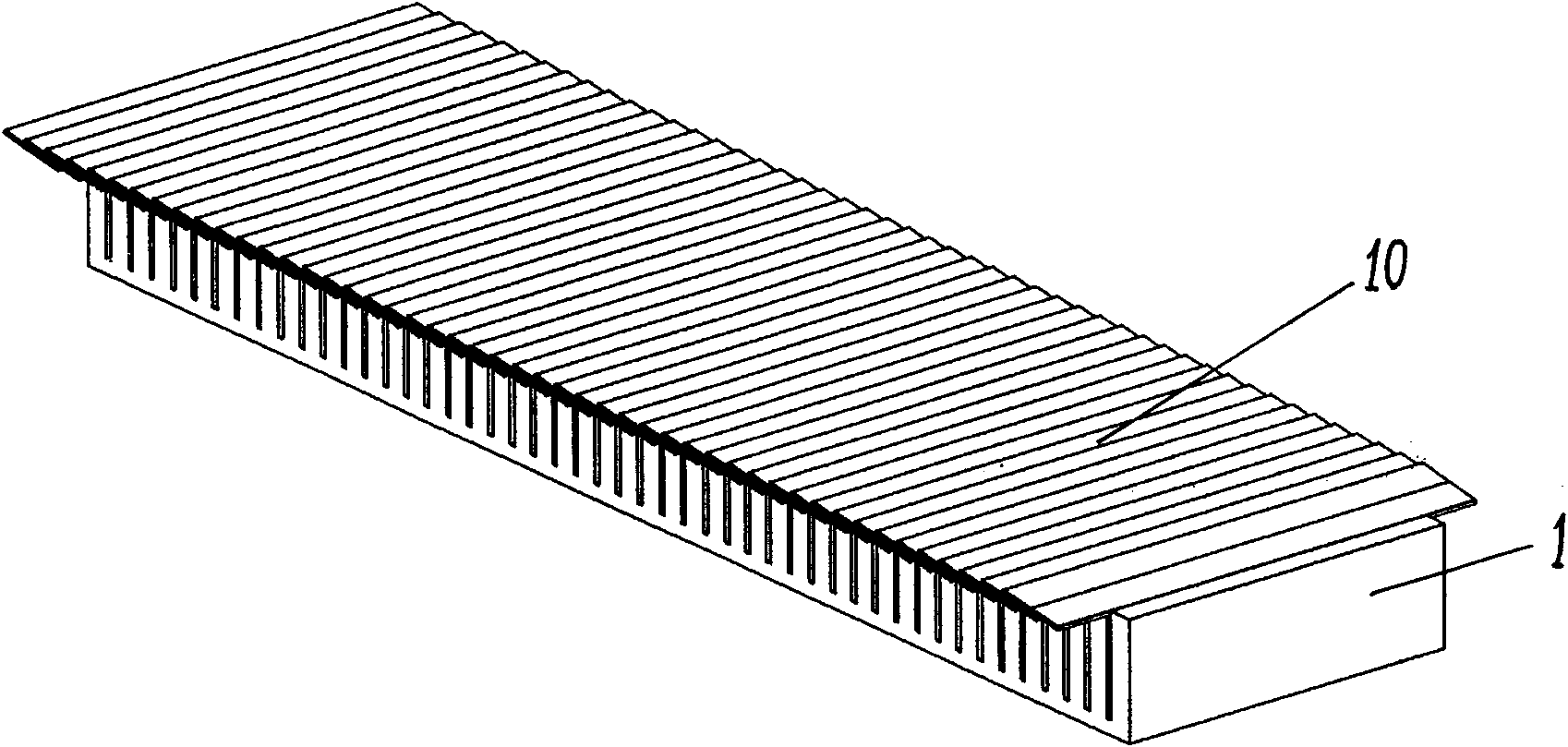

[0037] A device for collecting fins and arranging and combining them with flat tubes, first of all, needs to use the tube-arranging mold 1 for production. The pipe row mold 1 is formed by wire-cutting of aluminum profiles, and is provided with grooves arranged in parallel and at consistent intervals, which match the thickness of the flat pipe 10 and are slightly larger than the thickness of the flat pipe 10 . The top of the pipe row mold 1 boss is a jagged slope (see attached figure 1 ), to facilitate the "domino" arrangement of flat tubes 10 (see attached figure 2 ).

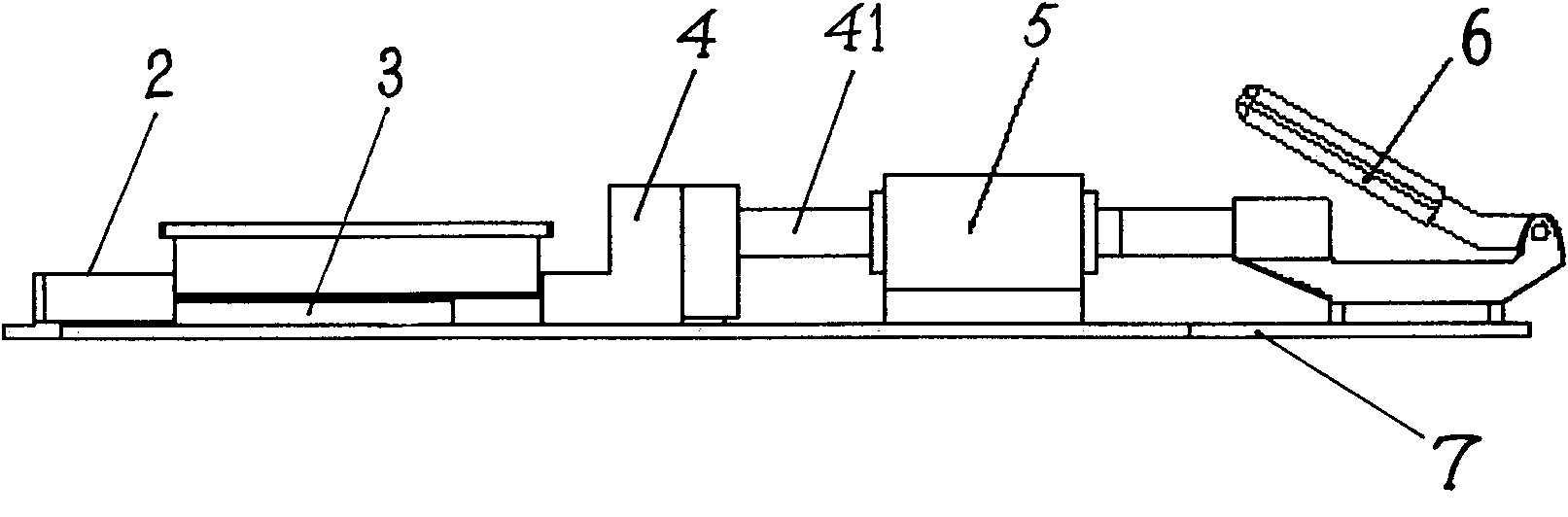

[0038] See attached image 3 with 4 .

[0039] The fin and flat tube collecting device assembly adopted in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com