Gray cast iron and production method thereof

A production method, the technology of gray cast iron, applied in the field of cast iron and its production, can solve the problems of poor casting performance, high casting manufacturing cost, high casting rejection rate, etc., and achieve the solution of large shrinkage tendency, reasonable production process, and superior casting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

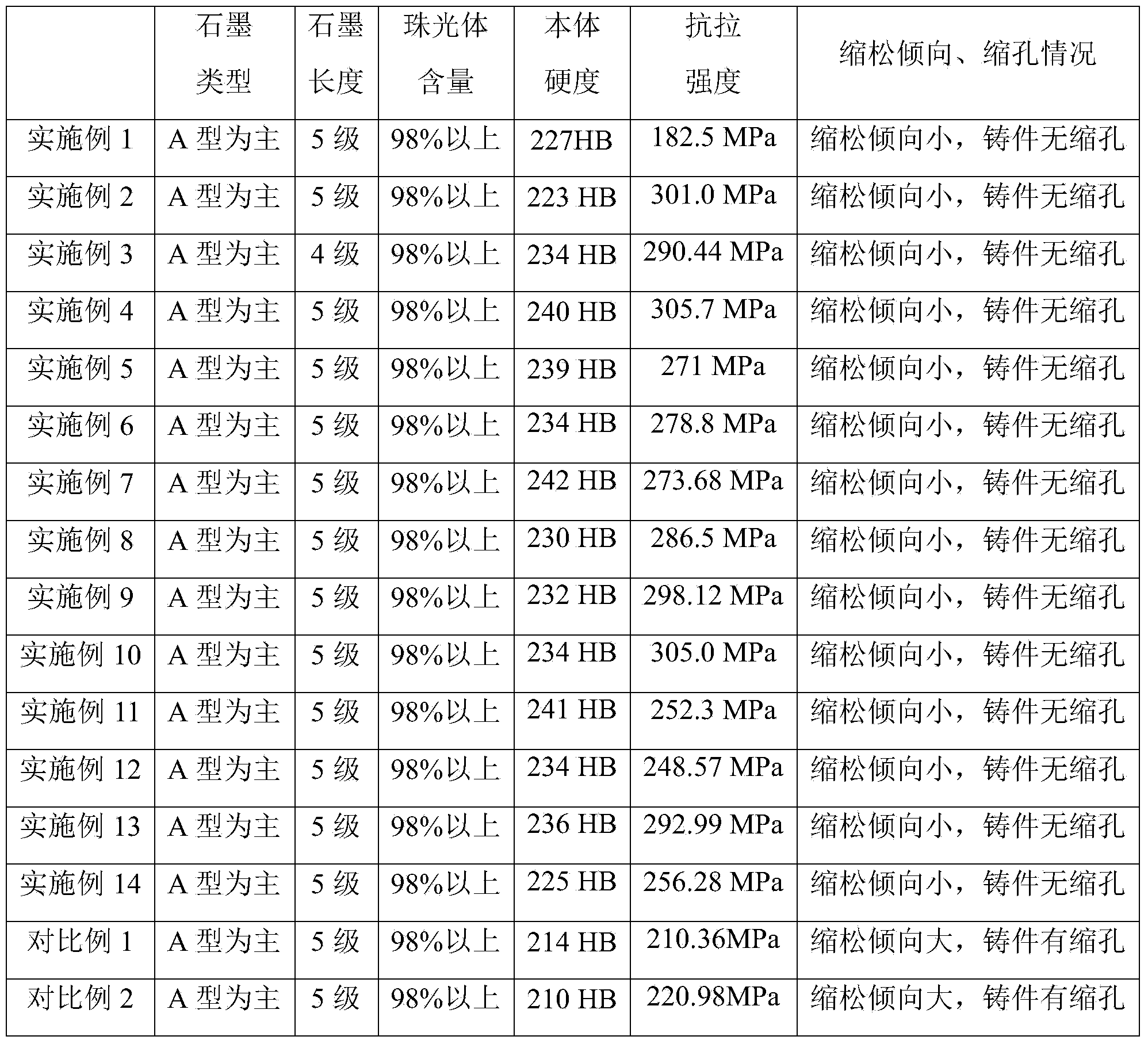

Examples

Embodiment 1

[0025] The weight percentage of each chemical component in the final molten mixture of furnace pretreatment is controlled as: C: 3.1%, Si: 1.8%, Mn: 0.8%, P: 0-0.04%, S: 0.1%, Cr: 0.4%, Cu: 0.5%, Sn: 0.06%, Sb: <0.02%, the balance is Fe. Finally, casting and molding.

Embodiment 2

[0027] The weight percentage of each chemical component in the final molten mixture of furnace pretreatment is controlled as: C: 3.1%, Si: 1.8%, Mn: 0.5%, P: 0.04%, S: 0.08%, Cr: 0.2%, Cu: 0.4% , Sn: 0.06%, Sb: <0.02%, and the balance is Fe. Finally, casting and molding.

Embodiment 3

[0029] The weight percentage of each chemical component in the final molten mixture of furnace pretreatment is controlled as: C: 3.2%, Si: 2.0%, Mn: 0.8%, P: 0.02%, S: 0.1%, Cr: 0.4%, Cu: 0.5% , Sn: 0.06%, Sb: <0.02%, and the balance is Fe. Finally, casting and molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com