Waste rubber powder/styrene-butadiene-styrene (SBS) composite modified asphalt and production process thereof

A technology of composite modified asphalt and production process, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of long process route, prolong production time, expensive and other problems, and achieve the effect of simple production process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

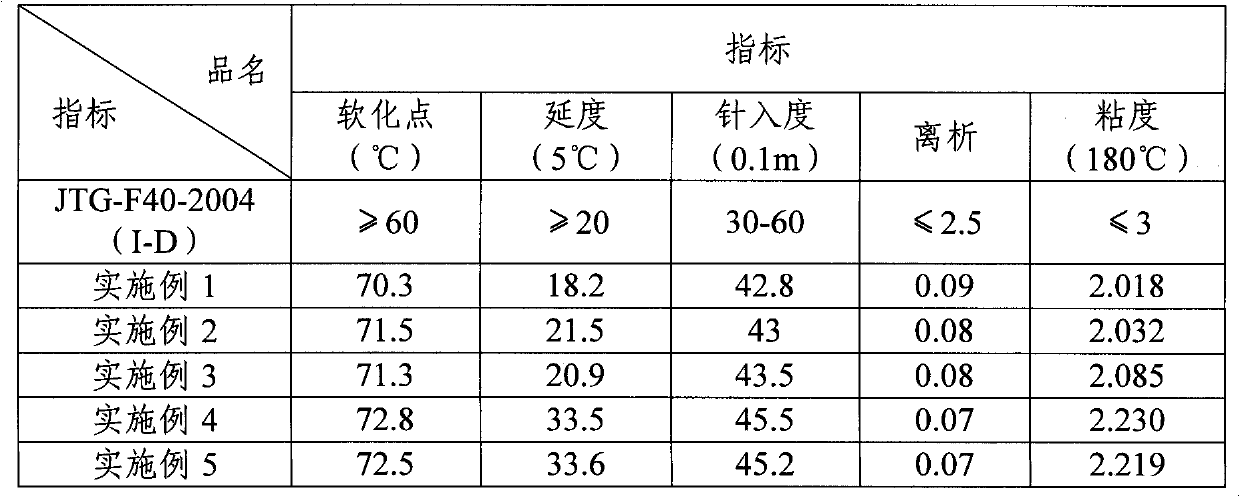

Examples

Embodiment 1

[0019] The invention is a waste rubber powder / SBS composite modified asphalt, its components include activator 0.3wt‰, penetrant 1wt‰, waste rubber powder 20wt%, SBS 0.2wt%, aromatic oil 2wt%, and the rest is matrix asphalt .

[0020] Among them, the activator is sulfur; the penetrating agent is diesel.

[0021] Wherein, the particle size of the waste rubber powder is 30 meshes, and the content of natural rubber hydrocarbons in the waste rubber powder is 35%.

[0022] Taking the above waste rubber powder / SBS composite modified asphalt as an example, its production process includes the following processing steps:

[0023] Step 1: Heat the base asphalt in the reactor to 180°C to melt;

[0024] The second step: keep warm and stir the base asphalt, add waste rubber powder, penetrant, SBS, aromatic oil, and activator to the above base asphalt at a temperature of 180-185°C to swell, and at the same time start the high-speed shearing machine cycle connected to the reactor Shearing...

Embodiment 2

[0028] The invention is a waste rubber powder / SBS composite modified asphalt, its components include activator 0.3wt‰, penetrant 1wt‰, waste rubber powder 20wt%, SBS 0.3wt%, aromatic oil 2wt%, and the rest is matrix asphalt .

[0029] Among them, the activator is sulfur, and the penetrating agent is diesel.

[0030] Wherein, the particle size of the waste rubber powder is 30 meshes, and the content of natural rubber hydrocarbons in the waste rubber powder is 35%.

[0031] Taking the above waste rubber powder / SBS composite modified asphalt as an example, its production process includes the following processing steps:

[0032] Step 1: Heat the base asphalt in the reactor to 190°C to melt;

[0033] The second step: keep warm and stir the base asphalt, add waste rubber powder, penetrant, SBS, aromatic oil, and activator to the above base asphalt at a temperature of 180-185°C to swell, and at the same time start the high-speed shearing machine cycle connected to the reactor Shea...

Embodiment 3

[0037] The invention is a waste rubber powder / SBS composite modified asphalt, its components include activator 0.3wt‰, penetrant 1wt‰, waste rubber powder 20wt%, SBS 0.4wt%, aromatic oil 2wt%, the rest is base asphalt .

[0038] Wherein, the activator is sulfur, and the penetrating agent is diesel.

[0039] Wherein, the particle size of the waste rubber powder is 30 mesh, and the content of natural rubber hydrocarbons in the waste rubber powder is 35%.

[0040] Taking the above waste rubber powder / SBS composite modified asphalt as an example, its production process includes the following processing steps:

[0041] Step 1: Heat the base asphalt in the reactor to 190°C to melt;

[0042] The second step: keep warm and stir the base asphalt, add waste rubber powder, penetrant, SBS, aromatic oil, and activator to the above base asphalt at a temperature of 180-185°C to swell, and at the same time start the high-speed shearing machine cycle connected to the reactor Shearing, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com