Producing process of quaternary ammonium type cation modifying starch

A technology of modified starch and production process, which is applied in the field of production technology of quaternary ammonium cationic modified starch, can solve the problems of low-level repeated extension of products, weak product market competitiveness, increased cost of production enterprises, etc. Effects of gelatinization temperature and retrogradation, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 1000 parts of starch into the mixer, start the mixer, add 5-20 parts of powdered sodium hydroxide, 0.2 parts of sodium hexametaphosphate, 30-80 parts of 3-chloro-2-hydroxypropyl with a concentration of 69% Chlorotrimethylammonium chloride (CHPTMA) solution, stirred at room temperature for 10-20 minutes, then fully mixed by a high-speed mixer, sent to the inlet of microwave far-infrared equipment, adjusting the thickness of the material layer to 3-6cm, and turning on microwave far-infrared equipment, adjust the temperature of the material at 50-150°C, keep it for 5-60 minutes, test the moisture content, viscosity and degree of substitution to reach 10-13%, 30-80mpa.s and 0.02-0.05 respectively, then put the material into the cooling compound When the temperature in the machine drops below 40°C, spray 8-20 parts of sulfuric acid solution with a concentration of 4% to 10% and add 5 to 15 parts of potassium ferrocyanide, and then mix thoroughly for 10 to 20 minutes to in...

Embodiment 2

[0022] Add 1000 parts of starch into the mixer, start the mixer, add 20-30 parts of composite catalyst composed of sodium metasilicate, sodium carbonate or sodium metaaluminate, 0.3 parts of epichlorohydrin, and active ether with a concentration of 69%. Chemical agent N-(2,3 epoxypropyl) trimethyl ammonium chloride (GTA) solution 30 ~ 90 parts, stir at room temperature for 10 ~ 15min, follow-up procedure is the same as Example 1, and then put this material into cooling complex When the temperature drops below 40°C in the dispenser, spray 8-15 parts of dilute hydrochloric acid solution with a concentration of 3%-8% and add 5-15 parts of sodium aluminosilicate, and then mix thoroughly for 10-20 minutes to increase and improve The various performances of the product meet the various requirements of users for the modified starch, and finally the product of the present invention is obtained by sieving and packaging.

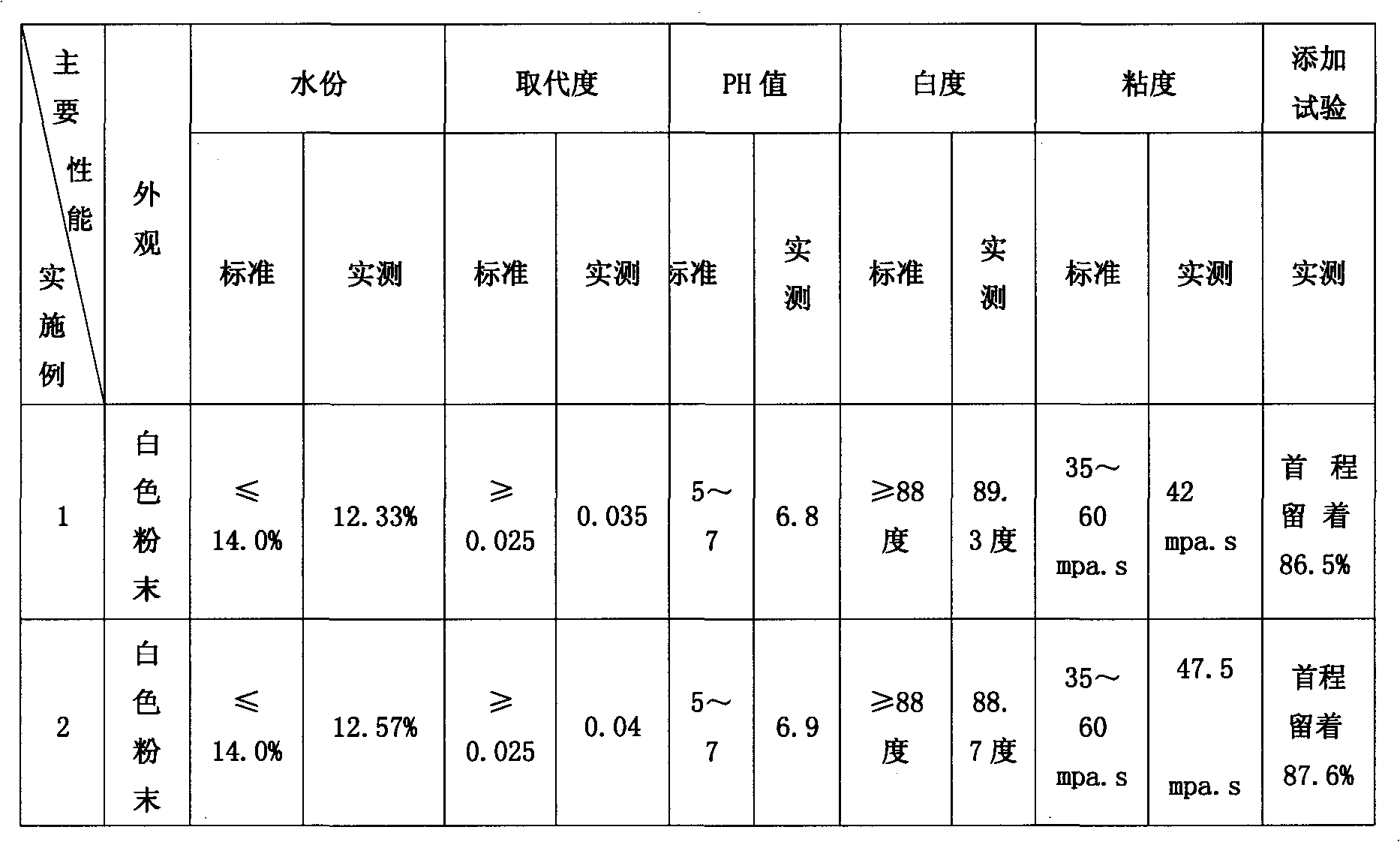

[0023] The modified starch obtained in the above examples is mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com